High efficiency spiral tunneling device and application method thereof

A high-efficiency, helical technology, applied to mining equipment, earthwork drilling, tunnels, etc., can solve problems such as low work efficiency, inconvenient soil and labor operation intensity, so as to improve tunneling efficiency, avoid manual lifting work, and improve output efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

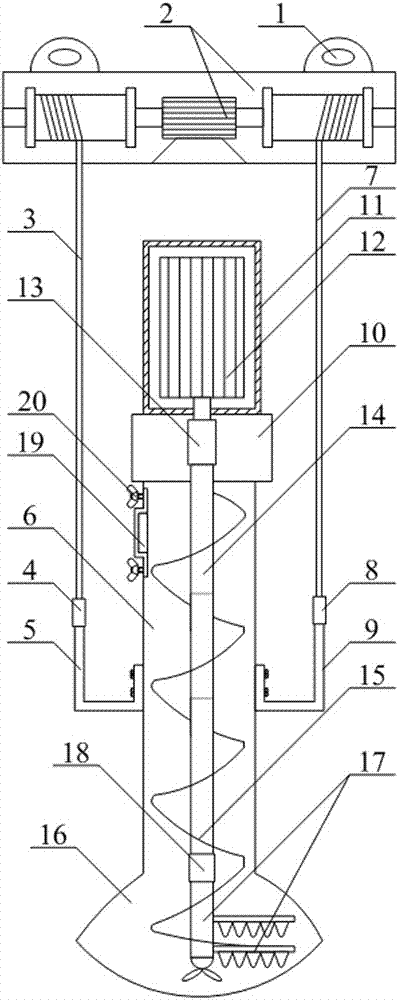

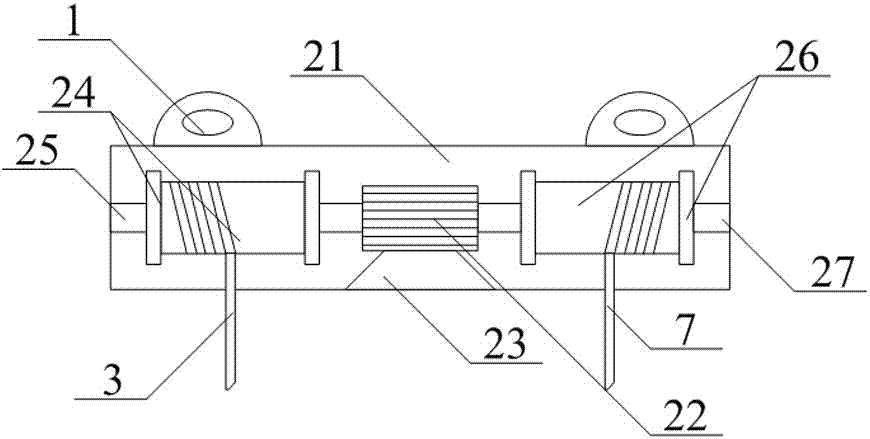

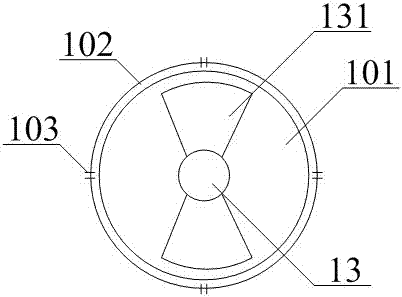

[0039] as attached figure 1 to attach Figure 4 shown

[0040]The present invention provides a high-efficiency spiral excavation equipment, including lug plate 1, hoist structure 2, first-level lifting rope 3, first-level lock 4, first-level hanger 5, outlet cylinder 6, second-level lifting rope 7, Secondary lock 8, secondary hanger 9, cooling tube structure 10, cooling shell 11, driving motor 12, primary coupling 13, screw shaft 14, screw blade 15, shield 16, fast screw-in shaft structure 17 , a secondary coupling 18, a lead-out door 19 and a quick release bolt 20, the lugs 1 are respectively welded on the left and right sides of the upper part of the hoist structure 2; one end of the primary rope 3 passes through a primary lock 4 is connected to the first-level hanger 5, and the other end is connected to the left part of the hoist structure 2; one end of the second-level lifting rope 7 is connected to the second-level hanger 9 through the second-level lock 8, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com