Short thermocouple calibration system

A technology of calibration system and thermocouple, applied in the direction of thermometer testing/calibration, measuring heat, measuring device, etc., can solve the problems of calibration hole depth, the inability of calibration hole to provide temperature field uniformity, affecting the development of short thermocouples, etc. Improve calibration accuracy, improve accuracy, and reduce the effect of temperature difference between holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

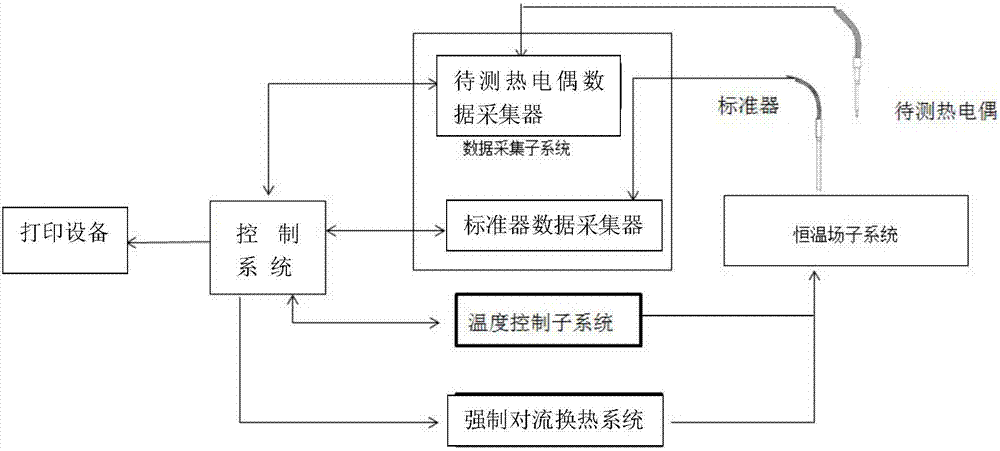

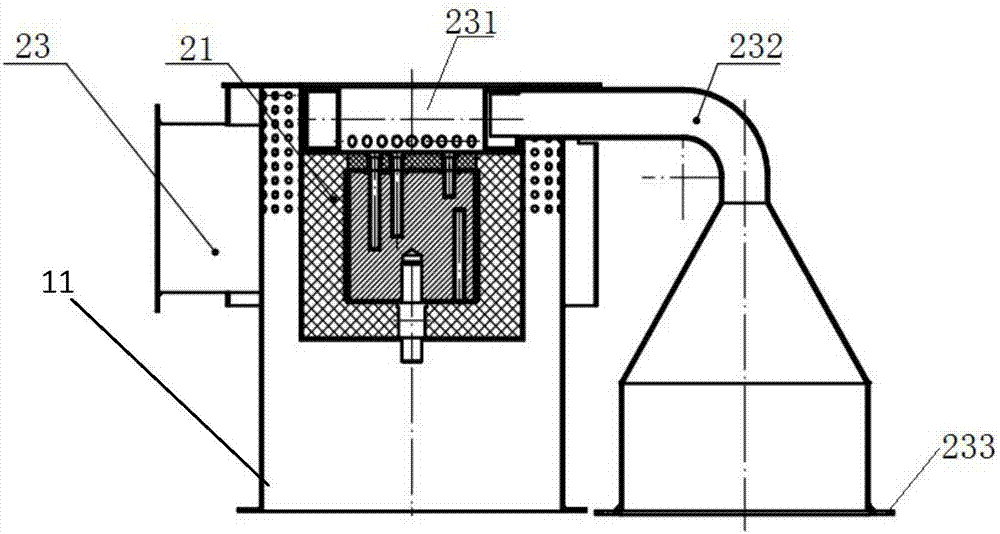

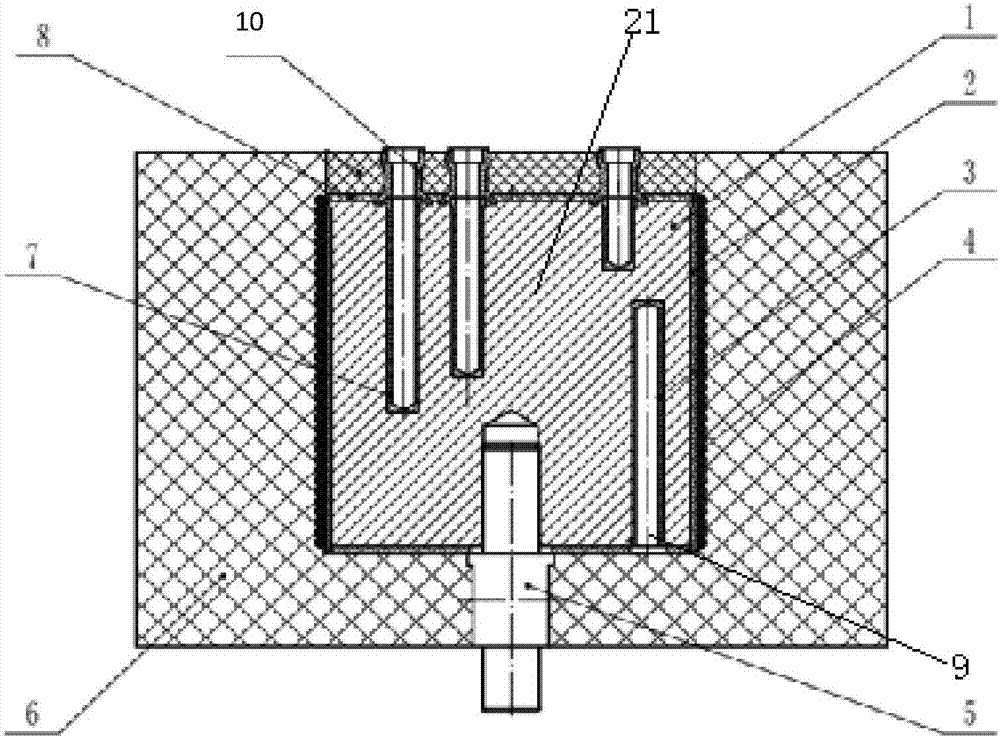

[0032] From figure 1 It can be seen that the short thermocouple calibration system of the present invention includes a control system, a constant temperature field subsystem, a temperature control subsystem connected with the control system and a data acquisition subsystem, and the temperature control subsystem is also connected with the constant temperature field subsystem. It may include a printing device connected to the control system and a forced convection heat exchange subsystem, and the forced convection heat exchange subsystem is located between the control system and the constant temperature field subsystem.

[0033] In the present invention, the control system sends control commands to the temperature control subsystem. The temperature control subsystem controls the temperature of the constant temperature field subsystem. The constant temperature field subsystem feeds back the temperature information collected by the temperature control sensor installed in it to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com