Mutton chop seasoning and preparation method thereof

A production method and seasoning technology, applied in the field of seasoning, can solve the problems of seasoning without lamb chops and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

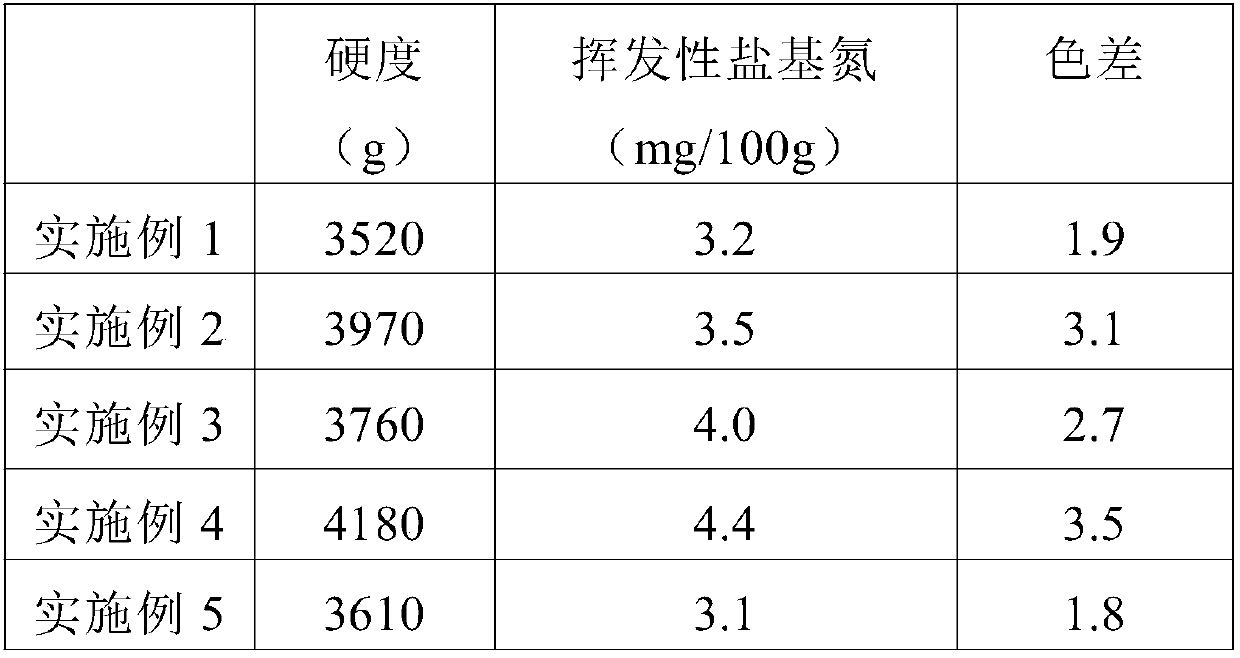

Examples

Embodiment 1

[0046] The preparation method of seasoning for lamb chops comprises the following steps:

[0047] S1: Grind Zanthoxylum bungeanum and pass through a 30-mesh sieve to obtain Zanthoxylum bungeanum powder; mix Zanthoxylum bungeanum powder with ethanol with a mass fraction of 75% (that is, an aqueous solution of ethanol, wherein the mass fraction of ethanol is 75%) at a solid-to-liquid mass ratio of 1:10 Uniform, under the condition of ultrasonic power 300W, ultrasonic frequency 35kHz, carry out ultrasonic extraction at 65°C for 2.5 hours to obtain the extract; centrifuge the extract at 3000 rpm for 15 minutes, discard the precipitate, take the supernatant at temperature Carry out rotary evaporation at 50°C, vacuum degree of 0.08MPa, and rotating speed of 60 rpm to remove the solvent, and obtain Zanthoxylum bungeanum oleoresin;

[0048] S2: uniformly mix Zanthoxylum bungeanum oleoresin, maltodextrin, and cornstarch in a mass ratio of 1:8:1 to obtain adsorption type Zanthoxylum bun...

Embodiment 2

[0052] The preparation method of seasoning for lamb chops comprises the following steps:

[0053]S1: Grind Zanthoxylum bungeanum and pass through a 30-mesh sieve to obtain Zanthoxylum bungeanum powder; mix Zanthoxylum bungeanum powder with ethanol with a mass fraction of 75% (that is, an aqueous solution of ethanol, wherein the mass fraction of ethanol is 75%) at a solid-to-liquid mass ratio of 1:10 Evenly, under the condition of microwave power 300W, carry out microwave extraction at 65°C for 2.5 hours to obtain the extract; centrifuge the extract at a speed of 3000 rpm for 15 minutes, discard the precipitate, and take the supernatant at a temperature of 50°C. The vacuum degree is 0.08MPa, and the rotation speed is 60 rpm to carry out rotary evaporation to remove the solvent to obtain the pepper oleoresin;

[0054] S2: uniformly mix Zanthoxylum bungeanum oleoresin, maltodextrin, and cornstarch in a mass ratio of 1:8:1 to obtain adsorption type Zanthoxylum bungeanum oleoresin;...

Embodiment 3

[0058] The preparation method of seasoning for lamb chops comprises the following steps:

[0059] S1: Grind Zanthoxylum bungeanum and pass through a 30-mesh sieve to obtain Zanthoxylum bungeanum powder; mix Zanthoxylum bungeanum powder with ethanol with a mass fraction of 75% (that is, an aqueous solution of ethanol, wherein the mass fraction of ethanol is 75%) at a solid-to-liquid mass ratio of 1:10 Evenly, carry out Soxhlet extraction for 2.5 hours to obtain the extract; centrifuge the extract at a speed of 3000 rpm for 15 minutes, discard the precipitate, and take the supernatant at a temperature of 50 °C, a vacuum of 0.08 MPa, and a speed of 60 Carry out rotary evaporation to remove solvent under rev / min, obtain Zanthoxylum bungeanum oleoresin;

[0060] S2: uniformly mix Zanthoxylum bungeanum oleoresin, maltodextrin, and cornstarch in a mass ratio of 1:8:1 to obtain adsorption type Zanthoxylum bungeanum oleoresin;

[0061] S3: Weigh each raw material by weight: 50 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com