Production system and production technology of fusion casting refractory material common mould

A technology for melting and casting refractory materials and production systems, which is applied to casting molding equipment, cleaning/processing machinery of casting mold materials, casting molds, etc., and can solve problems such as large manpower and material resources, environmental pollution, and long preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

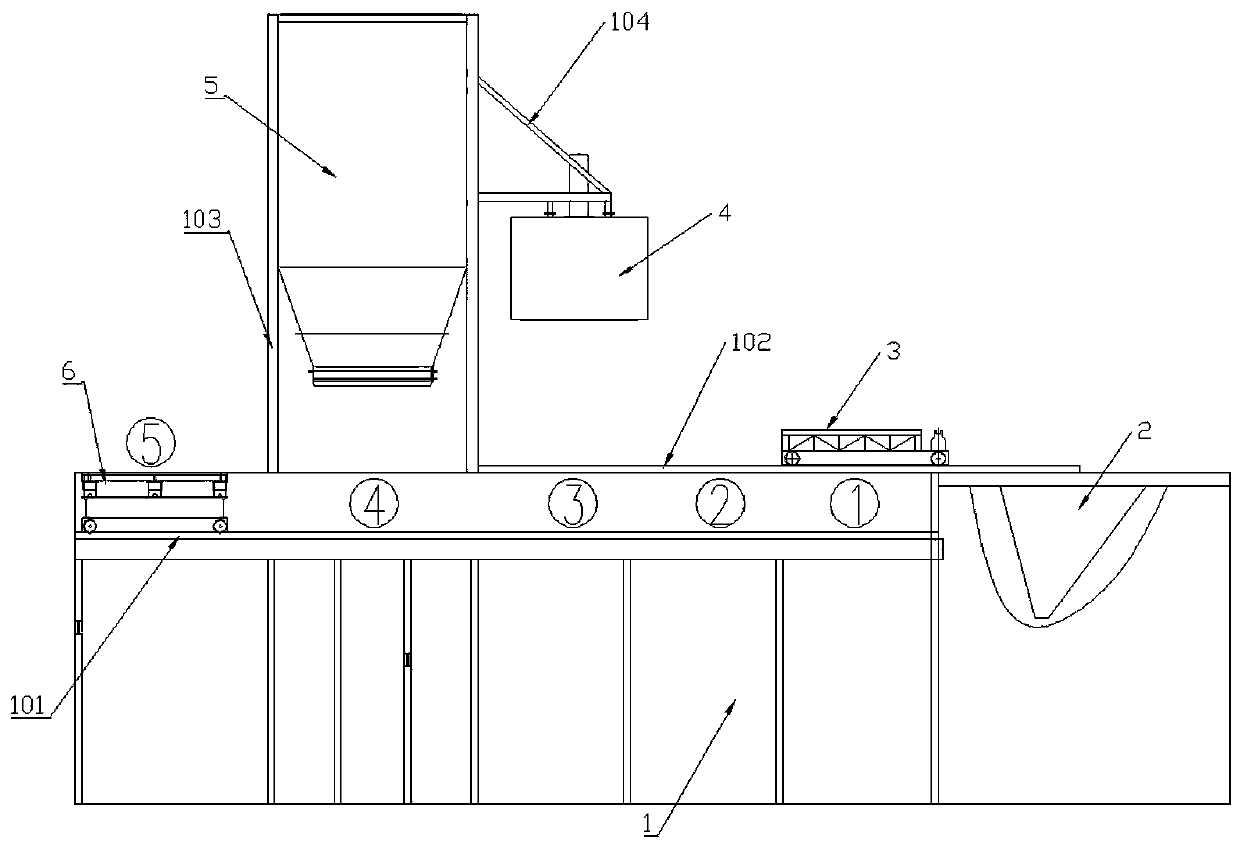

[0054] The specific embodiment of the present invention sees Figure 1-19 :

[0055] A general molding production system for melting and casting refractories, such as figure 1 , including a main frame and an auxiliary support positioned above the main frame and fixed with a sand bank, and also includes a film-covered box, a vibrating flat car and a film-supporting car, and the main frame is provided with a film-supporting machine for the film-supporting car to walk track, a vibrating track for the vibrating flat car to walk, the vibrating track is located under the supporting film track, the supporting film track is located on the upper surface of the main frame, and the right side of the main frame is provided with an outlet On the turntable, the lower outlet of the sand storehouse is provided with a rain-type sand lowering device.

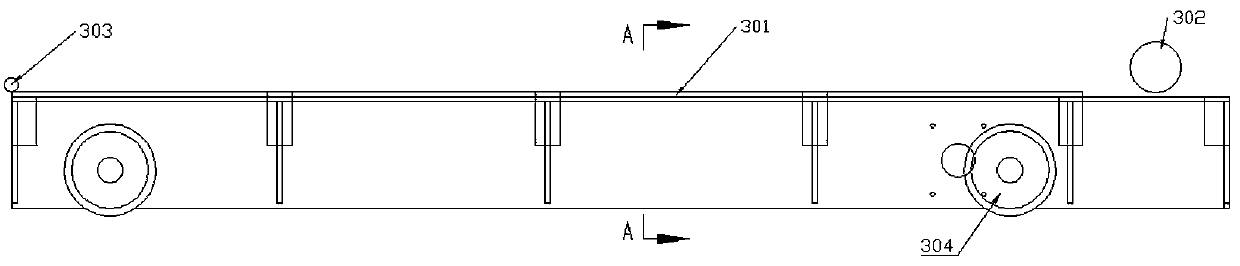

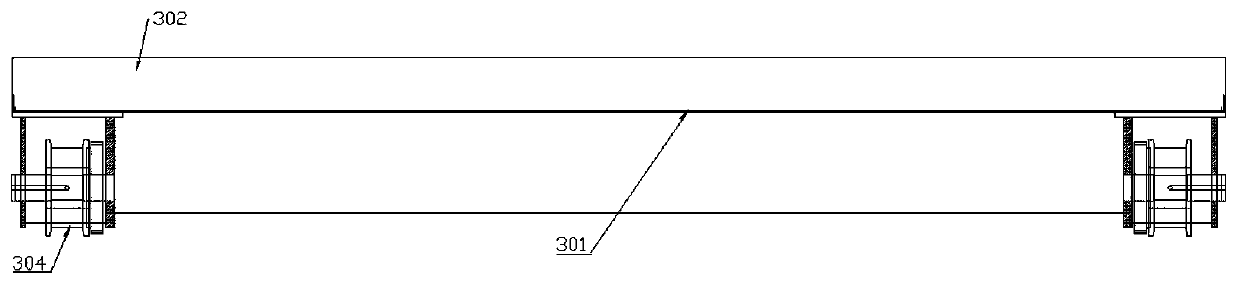

[0056] Such as Figure 4-9 , the inside of the film-coated box is provided with a film-coated box fixed on the auxiliary bracket with a tripo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com