A method of cladding tungsten copper on copper surface based on arc additive material

A copper surface and arc technology, applied in the field of tungsten copper cladding, can solve the problems of easy oxidation of copper alloys, preparation of coatings, high thermal conductivity, and achieve the effects of good electrical conductivity and high forming efficiency of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

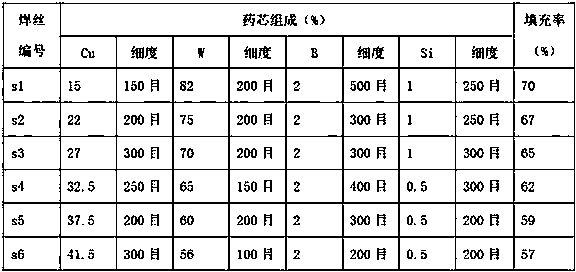

[0030] Example 1 Preparation of flux-cored welding wire.

[0031] Prepare flux-cored welding wire according to the formula in Table 1, and the specific preparation method is as follows:

[0032] a) Weigh the drug core components in proportion, then dry, sieve, and mix powder;

[0033] b) The copper strip is first cleaned and dried, and then processed into U-line grooves;

[0034] c) Fill the powder into the U-shaped groove copper strip according to a certain filling rate, and then roll it into a tubular welding wire by a closed forming roll;

[0035] d) The tubular welding wire is sent into the wire drawing machine, and the welding wire with a diameter of 2.0mm is obtained through drawing processing.

[0036] Table 1 welding wire formula

[0037]

Embodiment 2

[0038] Example 2 Preparation of a copper material whose surface is clad with tungsten copper.

[0039] According to the parameters in Table 2, tungsten copper is clad on the surface of copper material by arc additive material, and the products S1-S4 are obtained. The specific operation is as follows:

[0040] (1) Choose red copper as the base material, place the copper alloy sample in a closed argon-filled device, the pressure inside the device is 0.105MPa, and it has the function of continuous gas exchange, and the purity of the argon gas used is 99.99%; warm up;

[0041] (2) Adopt multi-layer and multi-channel tungsten argon arc welding, direct current connection, tungsten electrode diameter is 2.5mm, argon gas purity is 99.99%, set argon gas flow, welding current, welding speed, wire feeding speed, tungsten electrode distance.

[0042] Table 2 Parameter setting of arc additive

[0043] .

[0044] The thickness of the tungsten-copper layer of the obtained material is me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com