A modified flake graphite powder, resin-based carbon brush and preparation method thereof

A flake graphite and resin-based technology, applied in the field of modified flake graphite powder and its preparation, can solve the problems of poor arc ablation resistance, poor flexural strength, poor heat dissipation, etc., and achieve high flexural strength, low cost, matching good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

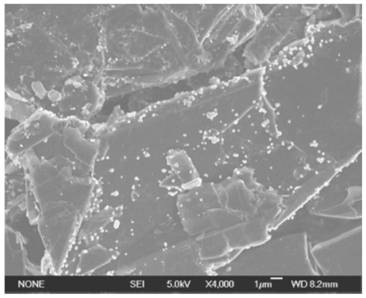

[0038] The modified flake graphite powder of this embodiment is composed of flake graphite and tungsten alloy powder coated on the surface of the flake graphite, wherein the tungsten alloy powder is tungsten copper alloy powder, its mass is 5% of the flake graphite, and the particle size is 0.2 μm, the SEM photo of the modified flake graphite is as shown in the accompanying drawing figure 1 shown.

[0039] The preparation method of the modified flake graphite powder of the present embodiment may further comprise the steps:

[0040] (1) preparation concentration is the carboxymethyl cellulose solution of 1%;

[0041] (2) Add the flake graphite powder into the carboxymethyl cellulose solution, after ultrasonic stirring for 2 hours under the condition of 60°C, place it in a tray and put it in an oven to dry the water, and pass the obtained material through a 200-mesh sieve to obtain Treated graphite powder, standby;

[0042] (3) Add the treated graphite powder into deionized w...

Embodiment 2

[0051] The modified flake graphite powder of this embodiment is composed of flake graphite and tungsten alloy powder coated on the surface of the flake graphite, wherein the tungsten alloy powder is tungsten copper alloy powder, its mass is 5% of the flake graphite, and the particle size is 0.2 μm.

[0052] The preparation method of the modified flake graphite powder of the present embodiment may further comprise the steps:

[0053] (1) preparation concentration is the carboxymethyl cellulose solution of 1%;

[0054] (2) Add the flake graphite powder into the carboxymethyl cellulose solution, after ultrasonic stirring for 2 hours under the condition of 60°C, place it in a tray and put it in an oven to dry the water, and pass the obtained material through a 200-mesh sieve to obtain Treated graphite powder, standby;

[0055] (3) Add the treated graphite powder into deionized water, stir at room temperature until the system is in a suspension state, add tungsten alloy powder un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com