Tail gas treatment method of chlorohydrin method propylene oxide plant

A method of propylene oxide and tail gas treatment technology, which is applied in the field of chlorohydrin method propylene oxide device tail gas treatment, can solve problems such as organic waste gas pollution, and achieve the effect of economical and safe process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

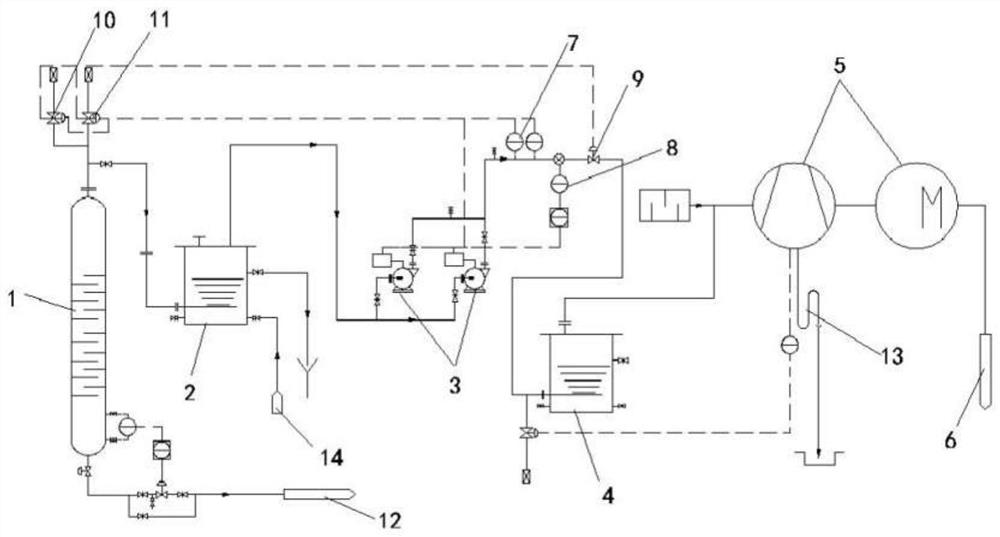

[0034] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings, and those skilled in the art can clearly understand the present invention and implement the present invention according to the detailed description. Without departing from the principles of the present invention, the features in different embodiments can be combined to obtain new implementations, or some features in certain embodiments can be replaced to obtain other preferred implementations.

[0035] figure 1 A method for treating tail gas of a propylene oxide plant by chlorohydrin method constituted according to a preferred embodiment of the present invention is shown. like figure 1 As shown, after the chloroalcoholization tail gas of the propylene oxide plant is removed the acid gas by the alkali washing tower 1, it is introduced into the safety water-sealed tank 2, and the water-sealed tank 2 is equipped with an air inlet, and the chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com