Application of hollow glass bead biological membrane carrier in wastewater treatment

A technology of biofilm carrier and glass microspheres, which is applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., and can solve solid waste treatment difficulties, complex processing techniques, and environmental hazards, etc. problems, to achieve the effect of easy microbial attachment, stable chemical properties, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

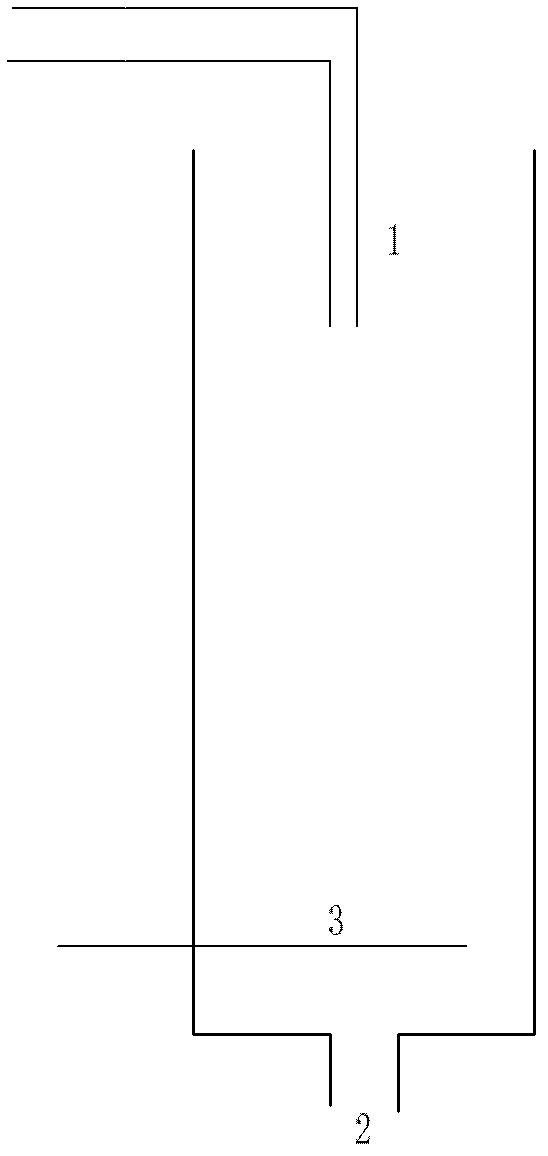

[0030] 1) Hanging film of biofilm reactor

[0031] The activated sludge in the airlift reactor operated stably in the laboratory was respectively inoculated into two aerobic biofilm reactors R with the same configuration and reactor size. 1 , R 2 ( figure 1 shown), where R 1 , R 2 The same amount of activated sludge inoculated in the same, the inoculated sludge volume is 1.5L, where R 1 The polyethersulfone hollow fiber membrane is added to the aerobic biofilm reactor as a biofilm carrier (it is fibrous in shape and is a supporting membrane, and its physical parameters are: inner diameter 0.4mm, outer diameter 0.8mm, membrane pore diameter 0.2×10 -3 mm, porosity 80%, total membrane area 0.36m 2 , manufacturer: provided by Shanghai Bingqi Chemical Technology Co., Ltd.); R 2 The carrier added in the reactor is the hollow glass microsphere (the parameter conditions are: a single mass of about 0.001g, a particle diameter of 0.01-0.075mm, and a density of 180-190Kg·m -3 , M...

Embodiment 2

[0037] The actual domestic sewage is used as the feed water of the biofilm reactor, and the parameters of the feed water are: (COD600mg / L, SS 150mg / L, pH 6-8), and the hollow glass microspheres are added to the biofilm reactor, and the biofilm The configuration of the reactor and the operation of the film-hanging process are the same as in Example 1. After the film-hanging is successful, the aeration rate is 0.8-1.0m 3 / h, (can also be adjusted according to actual needs, the adjustment range is based on the relationship between the influent flow rate of 1: (7.7 ~ 8.5) m 3 / h, the hydraulic retention time is 5h, and the biofilm reactor is operated, because the biofilm is easy to attach to the hollow glass beads, and because the hollow glass beads are light and easy to form a turbulent fluidization state with the downward flow and rising gas, The formation speed of the biofilm and the start-up time of the reactor are accelerated, so that the biomass retained in the reactor is la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com