Solder composition

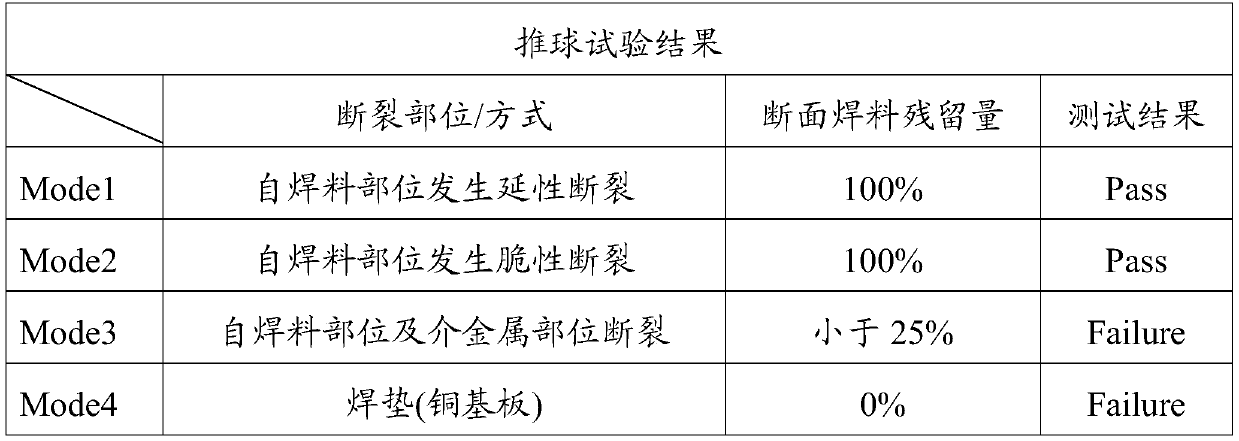

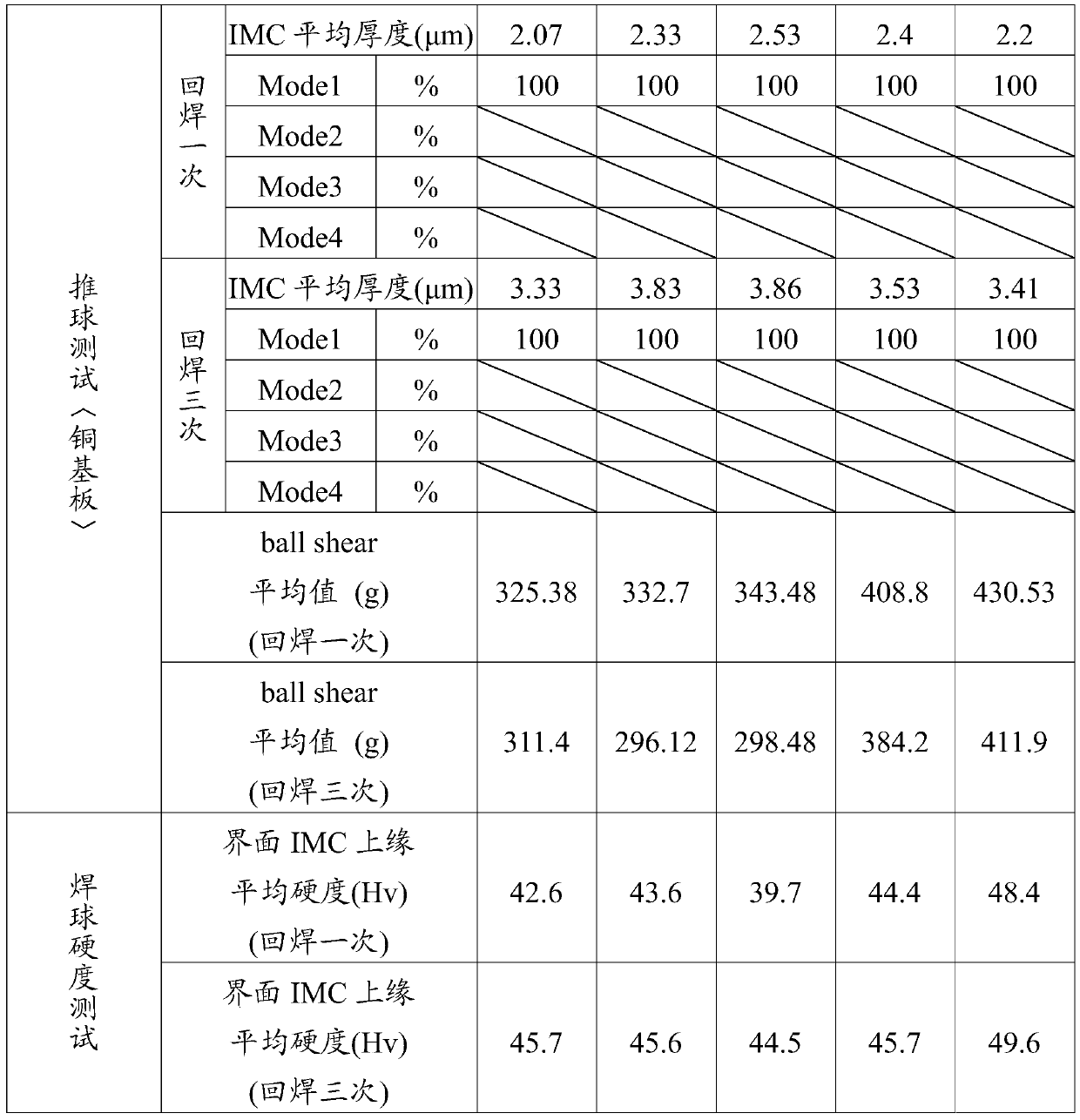

A composition and solder technology, used in welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of poor pad peeling, brittle fracture and fracture of self-bound metal, and improve yield strength and tensile strength. The effect of strength, good shear strength and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

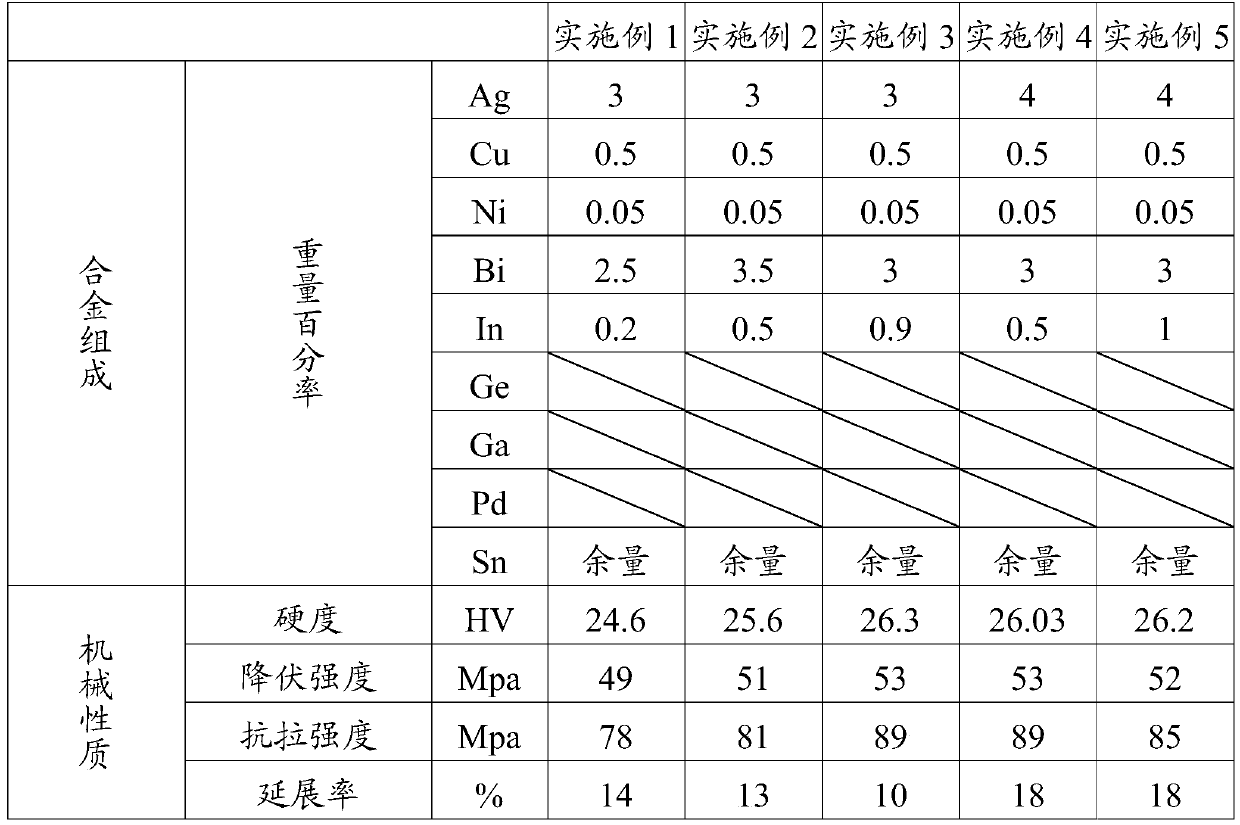

Embodiment 1

[0052] This embodiment provides a solder composition, which includes: 3 wt% silver, 0.5 wt% copper, 0.05 wt% nickel, 2.5 wt% bismuth, 0.2 wt% indium, and the balance tin.

Embodiment 2

[0054] This embodiment provides a solder composition, which includes: 3wt% silver, 0.5wt% copper, 0.05wt% nickel, 3.5wt% bismuth, 0.5 wt% indium, and the balance tin.

Embodiment 3

[0056] This embodiment provides a solder composition, which includes: 3wt% silver, 0.5wt% copper, 0.05wt% nickel, 3wt% bismuth, 0.9wt% % indium, and the balance tin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com