Early-strength binder for permeable concrete

A permeable concrete and early-strength technology, applied in the field of urban pavement structure, can solve problems such as weak innovation, achieve the effects of reducing sensitivity, reducing dosage, and improving water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

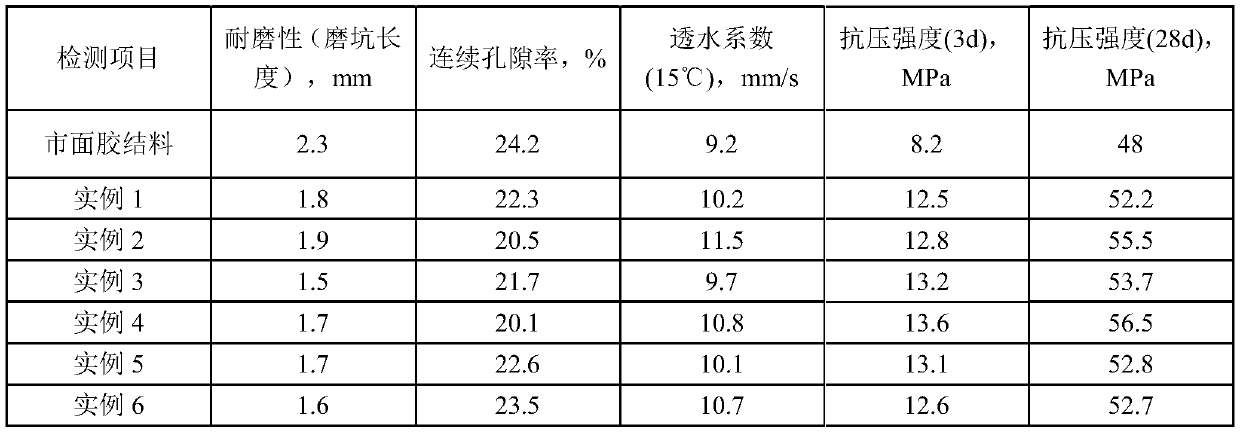

Examples

Embodiment 2

[0041] An early-strength binder for permeable concrete, its raw material formula includes the following components in weight percentage:

[0042] P.O52.5: 33.4%;

[0043] The composition is CaO: 60wt%, Al 2 o 3 : 25wt%, Fe 2 o 3 : 15wt% high-iron calcium aluminate cement: 18%;

[0044] Specific surface area 852m2 / kg ultrafine mineral powder: 27%;

[0045] Ferrous sulfate: 17%;

[0046] Wenlun glue: 0.6%;

[0047] Calcium bentonite: 1.3%;

[0048] Melamine superplasticizer powder: 0.7%;

[0049] Magnesium Stearate: 2.0%.

Embodiment 3

[0051] An early-strength binder for permeable concrete, its raw material formula includes the following components in weight percentage:

[0052] P.O42.5: 41%;

[0053] The composition is CaO: 62wt%, Al 2 o 3 : 23wt%, Fe 2 o 3 : 15wt% high-iron calcium aluminate cement: 11%;

[0054] Specific surface area 918m 2 / kg ultrafine mineral powder: 24%;

[0055] Zinc sulfate: 15%;

[0056] Natural gum: 1.7%;

[0057] Calcium bentonite: 2.2%;

[0058] Melamine superplasticizer powder: 1.0%;

[0059] Zinc stearate: 4.1%.

Embodiment 4

[0061] An early-strength binder for permeable concrete, its raw material formula includes the following components in weight percentage:

[0062] P.O52.5R: 48.5%;

[0063] The composition is CaO: 64wt%, Al 2 o 3 : 23wt%, Fe 2 o 3 : 13wt% high iron type calcium aluminate cement: 13%;

[0064] Specific surface area 863m 2 / kg ultrafine mineral powder: 19%;

[0065] Magnesium sulfate: 12%;

[0066] Wenlun rubber: 1.9%;

[0067] Sodium bentonite: 3.1%;

[0068] Melamine superplasticizer powder: 0.5%;

[0069] Aluminum stearate: 2.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com