A PDMS-based elastic film that can quickly self-heal without external stimulation and its preparation method

A technology of elastic film and external stimulation, applied in the field of functional film, to achieve the effect of high repair efficiency, time reduction and repair efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

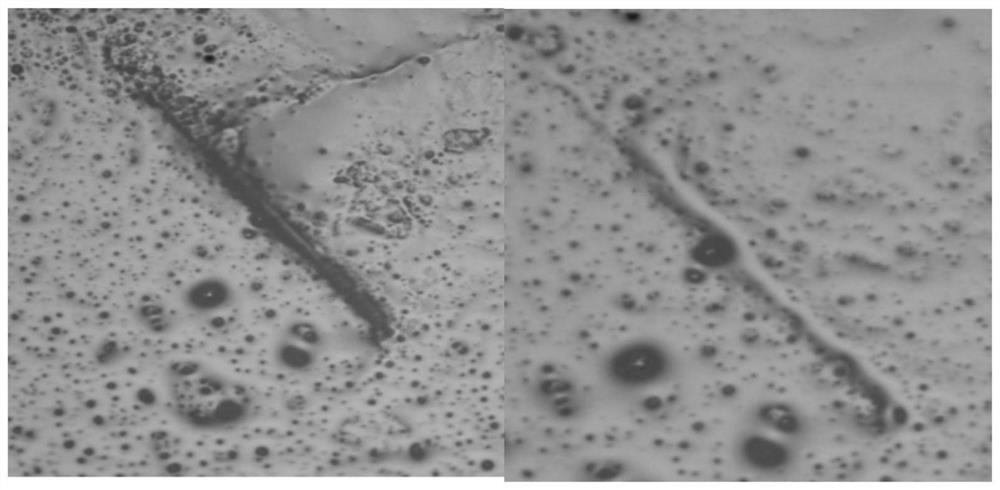

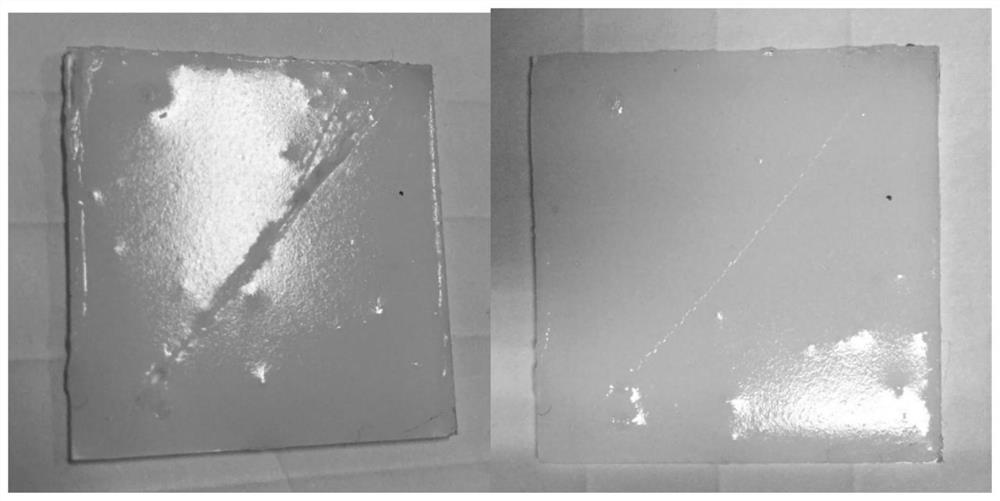

Image

Examples

preparation example Construction

[0039] A method for preparing a fast self-healing elastic film based on PDMS without external stimulation comprises the following steps:

[0040] Step 0: surface treatment of the rigid glass substrate;

[0041]Rigid glass pretreatment: The rigid glass substrate was ultrasonically cleaned in deionized water, acetone and absolute ethanol for 15-30 min, and then dried at 60-80°C for 30-40 min; hydrophilic treatment: the cleaned The final rigid glass substrate is ultrasonically cleaned in a mixture of hydrogen peroxide and concentrated sulfuric acid with a volume ratio of 7:1-7:3 for 30-45 min, and then dried at a temperature of 60-80°C for 30-40 min; Put the hydrophilic treated glass substrate in a beaker, add 2-5 ml of trimethylchlorosilane (TMCS) dropwise and seal the beaker, put it in a constant temperature water bath and heat it in a water bath at 60-80°C 45-60 min.

[0042] Step 1: preparing a chain polymer material by using hydroxyl or amino-terminated polydimethylsiloxan...

specific Embodiment 1

[0047] A fast self-healing elastic film based on PDMS without external stimulation: including 1.4 parts by weight of hydroxyl-terminated polydimethylsiloxane; 4 parts by weight of polyacrylic acid (PAA); 1 part by weight of polyethyleneimine; also including 0.08 N,N'-dicyclohexylcarbodiimide (DCC) in parts by weight, 4-dimethylaminopyridine (DMAP) in 0.02 parts by weight, polydimethylsiloxane (PDMS) in 2 parts by weight, 0.2 parts by weight part polydimethylsiloxane (PDMS) curing agent.

[0048] A method for preparing a fast self-healing elastic film based on PDMS without external stimulation comprises the following steps:

[0049] Step 0: Cleaning, hydrophilic and hydrophobic treatment on the surface of the rigid glass substrate

[0050] Rigid glass pretreatment: The rigid glass substrate was ultrasonically cleaned in deionized water, acetone and absolute ethanol for 30 minutes, and dried in a blast drying oven at 60°C for 30 minutes;

[0051] Hydrophilic treatment: Ultraso...

specific Embodiment 2

[0063] A fast self-healing elastic film based on PDMS without external stimulation: including 4 parts by weight of hydroxyl-terminated polydimethylsiloxane; 4 parts by weight of polyacrylic acid (PAA); 1 part by weight of polyethyleneimine; also including 0.12 Parts by weight of N,N'-dicyclohexylcarbodiimide (DCC), 0.04 parts by weight of 4-dimethylaminopyridine (DMAP), 2 parts by weight of polydimethylsiloxane (PDMS), 0.2 parts by weight part polydimethylsiloxane (PDMS) curing agent.

[0064] A method for preparing a fast self-healing elastic film based on PDMS without external stimulation comprises the following steps:

[0065] Step 0: Cleaning, hydrophilic and hydrophobic treatment on the surface of the rigid glass substrate

[0066] Rigid glass pretreatment: The rigid glass substrate was ultrasonically cleaned in deionized water, acetone and absolute ethanol for 30 minutes, and dried in a blast drying oven at 80°C for 30 minutes;

[0067] Hydrophilic treatment: Ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com