Regeneration method of semisynthesis waste engine oil

A waste oil, semi-synthetic technology, applied in the direction of lubricating composition, can solve the problems of long regeneration cycle, low regeneration quality, difficult to remove oil oxides, etc., and achieve the effect of short regeneration cycle and high regeneration quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

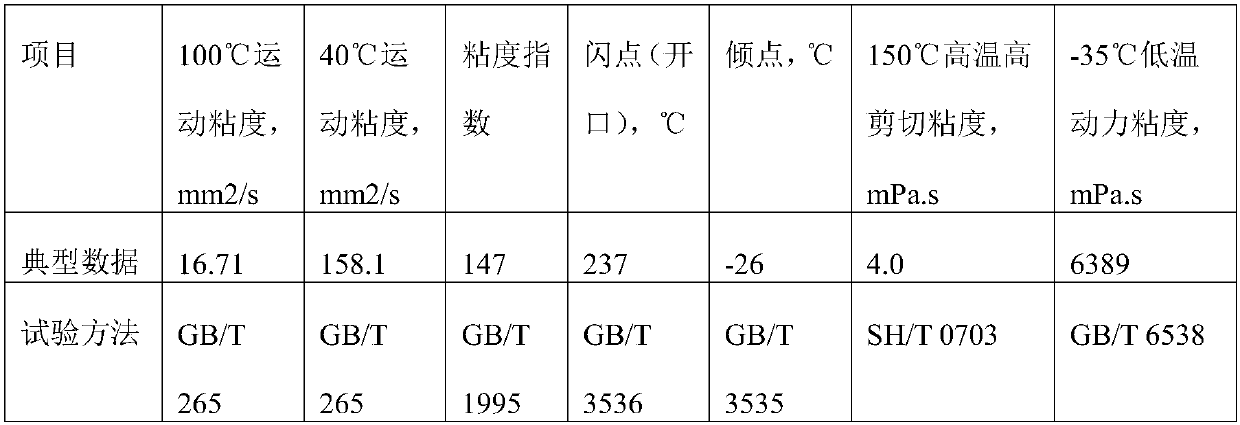

Embodiment 1

[0018] A method for regeneration of semi-synthetic waste engine oil, the steps of which are:

[0019] (1) Pretreatment

[0020] Put 100 parts of Shell semi-synthetic 5w-30 waste engine oil into a plastic container, add 3 parts of alum and 5 parts of polysilicate flocculant (PSAA), shake and stir for 50 minutes, let it stand for 3 hours, pour it into a centrifuge, 5000r / min Centrifuge for 5 minutes, collect the upper layer oil to obtain the first-stage upper layer clear oil; then add 20 parts of 3mol / L sulfuric acid solution to the first-stage upper layer clear oil, put it in a constant temperature box, set the temperature at 60°C, shake and stir for 20 minutes, and keep it warm After 12 hours, take it out and seal it, let it settle naturally at room temperature for 1 day, collect the upper layer oil to obtain the second-stage upper layer clear oil; add 0.2mol / L sodium hydroxide solution to the second-stage upper layer clear oil, wash the oil until neutral, add Wash with 30 pa...

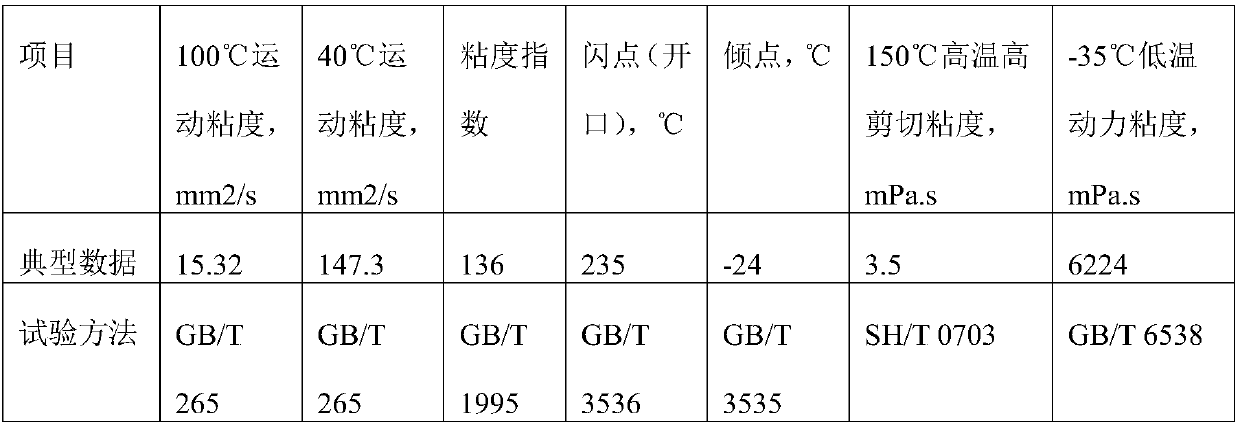

Embodiment 2

[0028] A method for regenerating semi-synthetic waste engine oil, the steps of which are:

[0029] (1) Pretreatment

[0030] Take 100 parts of Shell fully synthetic 5w-30 waste engine oil into a plastic container, add 3 parts of alum and 3 parts of polysilicate flocculant (PSAA), shake and stir for 50 minutes, let stand for 2 hours, centrifuge at 4000r / min for 3 minutes, and collect the upper layer The oil was obtained from the first-stage upper layer clear oil; then 20 parts of 3mol / L sulfuric acid solution was added to the first-stage upper layer clear oil, placed in a constant temperature box, set the temperature at 55°C, oscillated and stirred for 10 minutes, kept warm and stood for 12 hours, took out and sealed , naturally settle at room temperature for 1 day, collect the upper layer oil to obtain the second-stage supernatant clear oil; add 0.2mol / L sodium hydroxide solution to the second-stage upper layer clear oil, wash the oil to neutrality, add 20 parts of water to wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com