Siphon floor drain

A floor drain and siphon technology, applied in the field of bathroom accessories, can solve the problems of narrow water flow channels, easy to throw away and bend the buckled bowl, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

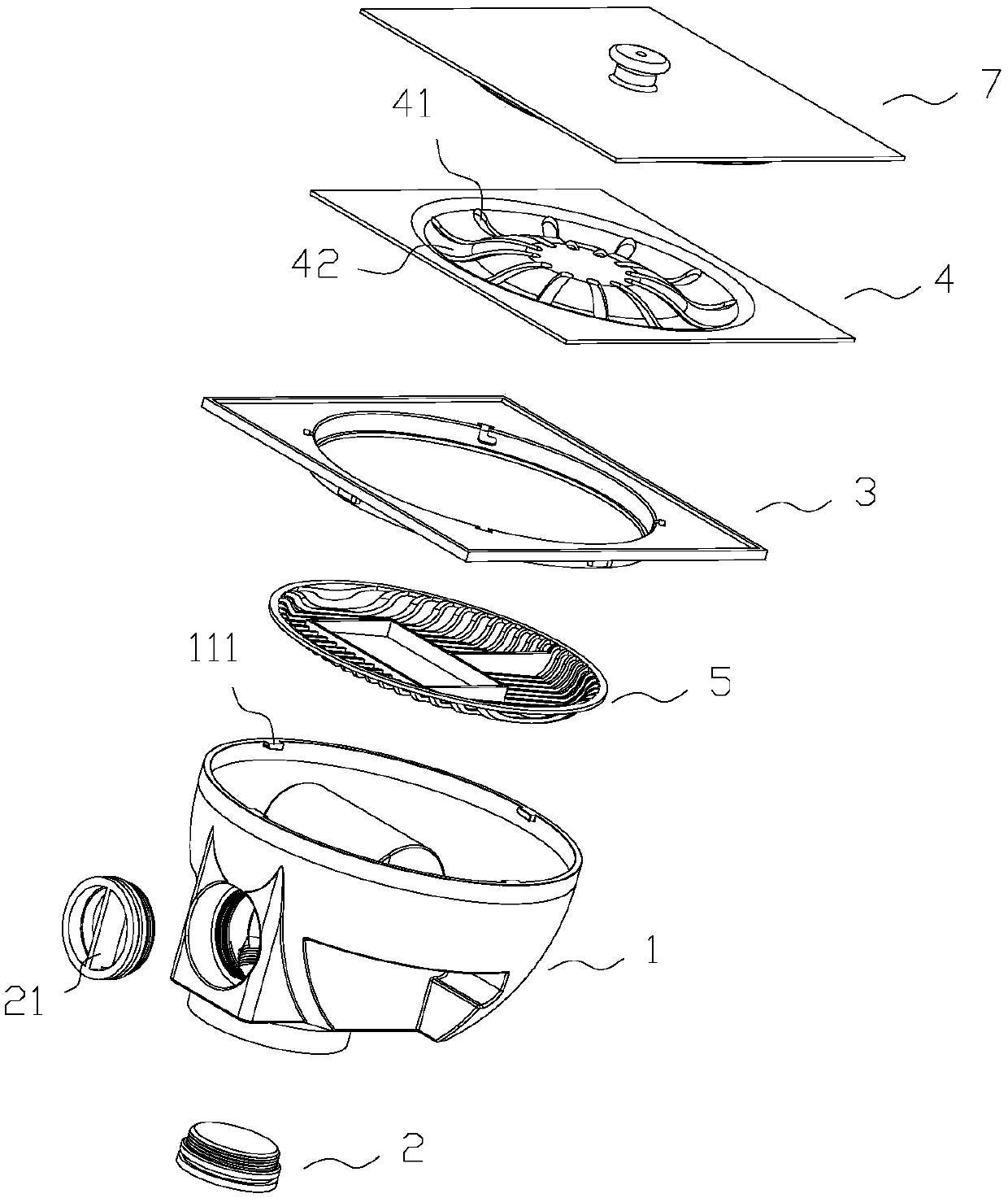

[0028] Embodiment 1 A kind of siphon floor drain

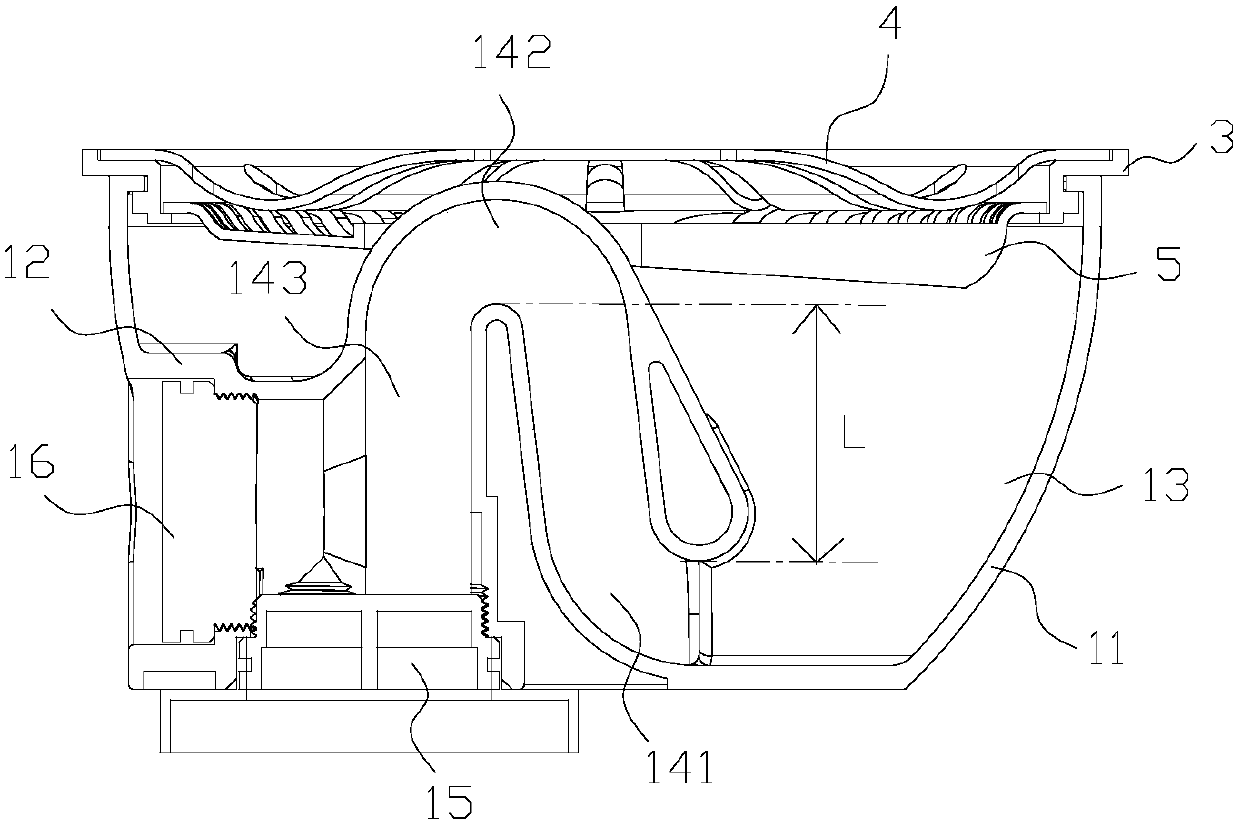

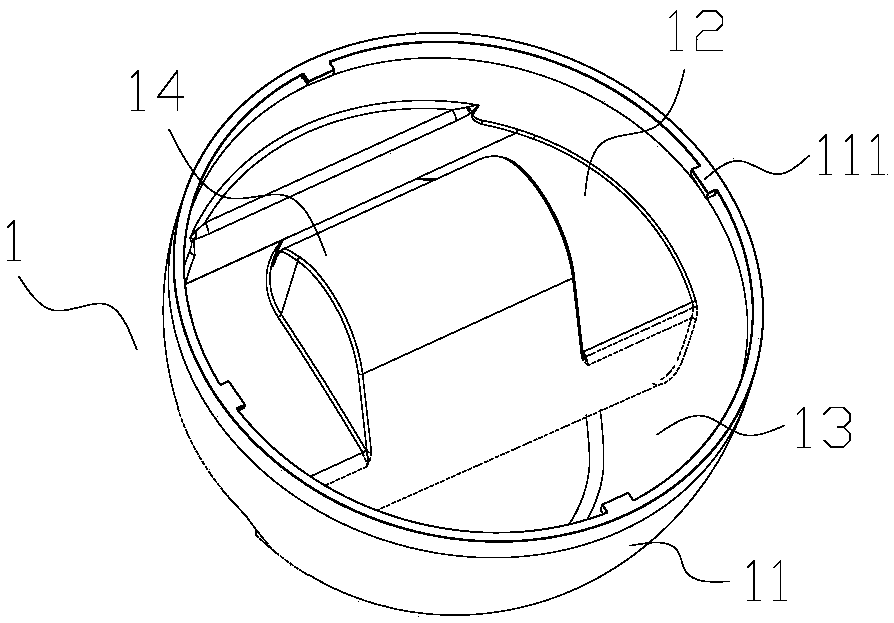

[0029] like Figure 1-6 As shown, the siphon floor drain includes a siphon body 1 and a plug 2; the siphon body is a shell 11 with an upper opening, one side of the shell cavity is provided with a drain table 12, and the other side of the shell cavity is a trap 13. An inverted U-shaped flat siphon 14 is provided on the discharge platform, and the flat siphon includes a water inlet pipe 141, an elbow 142 connected to the end of the water inlet pipe, and an outlet pipe 143 connected to the end of the elbow; The elbow is protruded on the discharge platform, the inlet pipe is connected with the outlet of the water trap, and the end of the outlet pipe is provided with a straight outlet 15 and a horizontal outlet 16; the plug is installed on the straight outlet or the horizontal outlet. on the drain.

[0030] This application adopts the principle of toilet siphon. On the one hand, an inverted U-shaped flat siphon and trap are arra...

Embodiment 2

[0040] Embodiment 2 A siphon floor drain applied to a washing machine

[0041] like Figure 6-9 As shown, the present invention also provides a siphon floor drain applied to a washing machine. Specifically, the siphon floor drain also includes a snap-in sleeve 6 arranged between the grate and the garbage filter on the basis of the embodiment; The in-type casing includes a mounting plate 61 and a pipe body 62 arranged on the mounting plate; the mounting plate is provided with radial drainage holes to facilitate drainage; the outer peripheral edge of the mounting plate is provided with a limit bump 611, The tray is provided with a guide groove 35 for installing the limit protrusion and an L-shaped limit groove 36 for limiting the movement of the limit protrusion; the guide groove is connected with the L-shaped limit groove; the guide groove is located on the hollow tray The upper surface of the upper surface of the L-shaped limit groove is located on the annular installation ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com