Supporting system for connection position of fabricated shear wall slab with bottom with height difference and installing method

A support system and shear wall technology, applied in the direction of wall, building material processing, building components, etc., can solve the problem of time-consuming and labor-intensive post-cast formwork support for nodes, and meet construction safety requirements, save costs, and meet construction accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

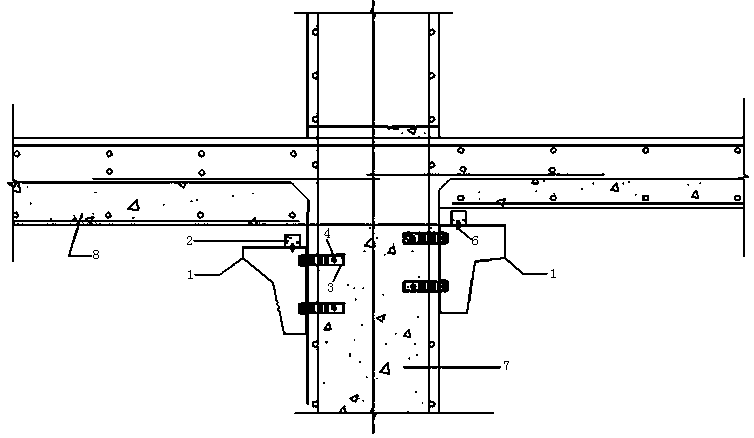

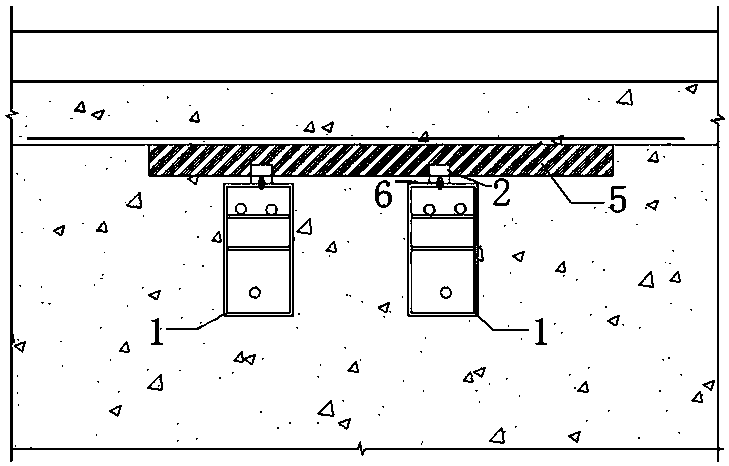

[0032] Such as Figure 1-7 As shown, at the joint of the middle support plate end of the prefabricated concrete structure shear wall (there is a height difference at the bottom of the plate), the prefabricated plate 8 is supported by the pre-embedded pipe fitting 3 pre-buried in the precast concrete shear wall 7 as a fulcrum , Cancel the vertical support of the lower part of the plate 8. It can be dismantled after the construction is completed without affecting the original structure. It has no effect on the later decoration. The on-site operation is also relatively simple, which can effectively solve the problems of construction difficulties when the primary and secondary beams are overlapped, and the reinforcement, support and removal of the post-cast joint formwork. Under the premise of reasonable construction, the entire support frame has the necessary bearing capacity and rigidity, and meets the safety requirements of on-site construction.

[0033] This embodiment is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com