A method and device for adjusting the focal length of a microlens array

A micro-lens array and micro-mirror array technology, which is applied in the field of micro-optical elements, can solve the problems of complex structure of adjustable focus micro-lenses, and achieve the effects of simple structure, convenient operation and fast adjustment speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

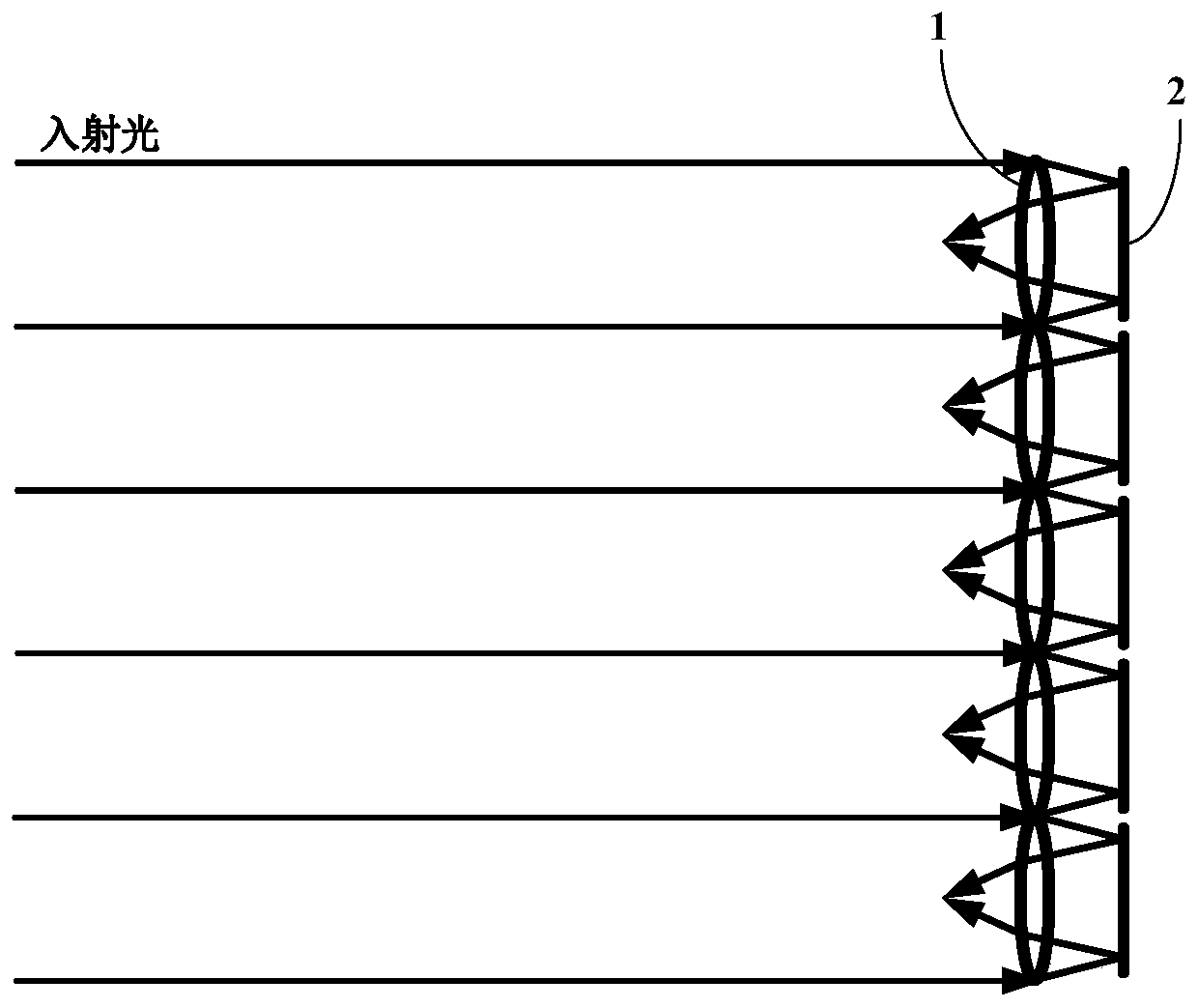

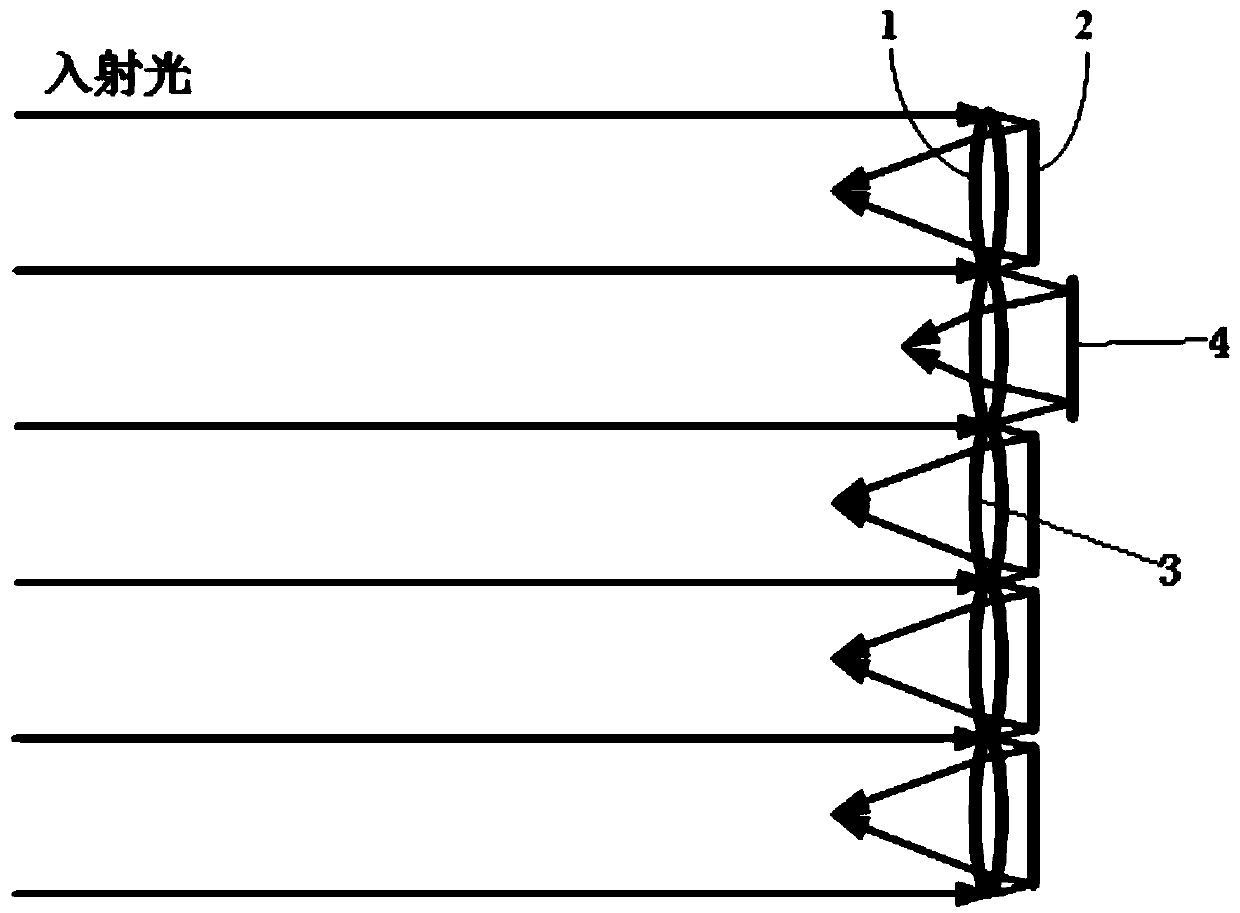

[0029] The device for adjusting the focal length of the microlens array includes a microlens array and a micromirror array. The microlens array and the micromirror array have the same unit spacing. The incident light is divided and converged after passing through the microlens array, and then enters the micromirror array. The surface is reflected, so that it passes through the microlens array again and finally converges into an array of light spots in front of the microlens array. Each micromirror of the micromirror array can move back and forth along the optical axis, thereby changing the position of the focused light spot, and realizing the adjustment and change of the focal length of the microlens array. The number of micromirrors moving back and forth is 1 or several, and the focal length of individual or several microlenses is changed; the micromirrors are transmissive.

[0030] Such as figure 1 The method for adjusting the focal length of the microlens array in the pres...

Embodiment 2

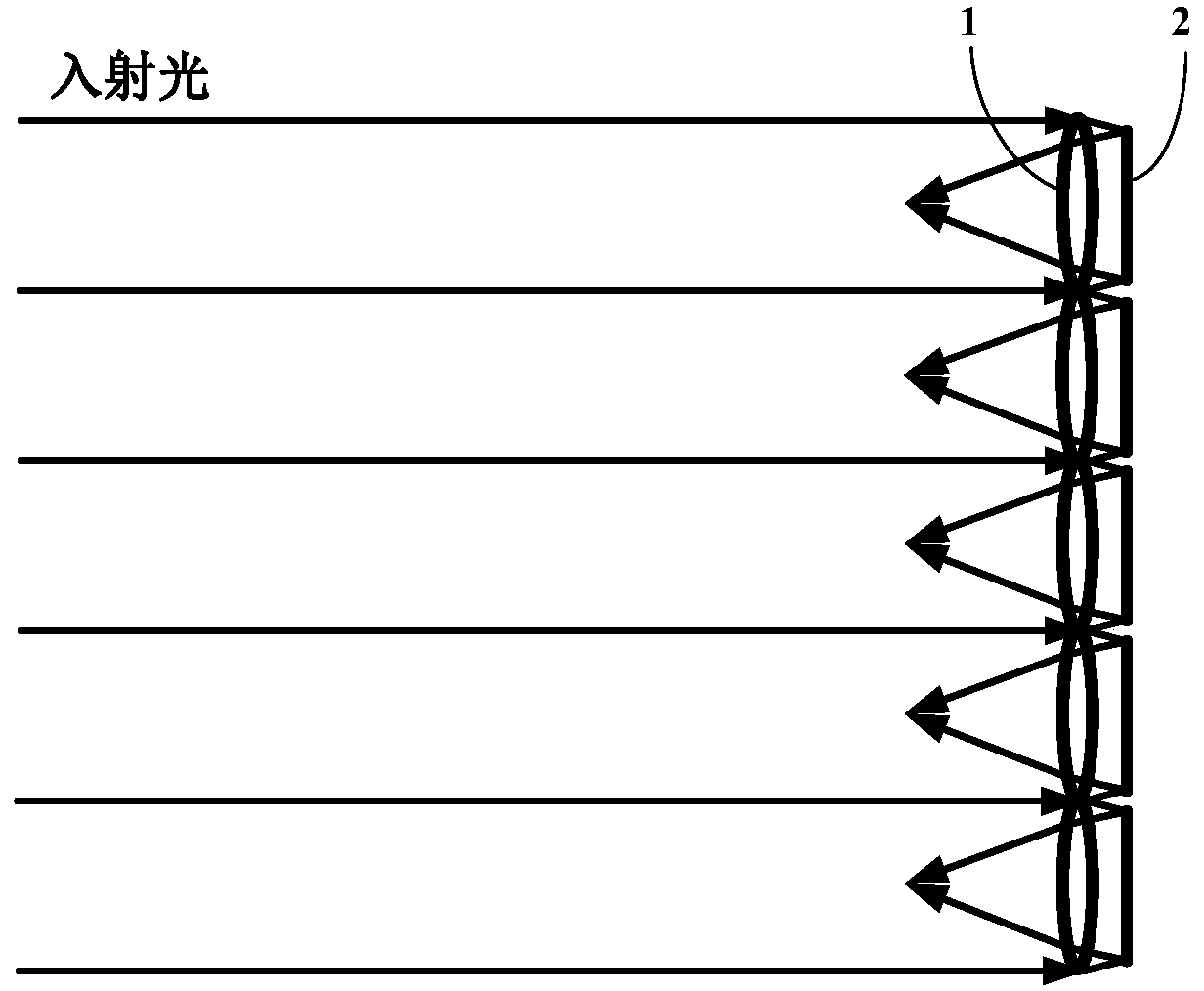

[0033] Other content is as content in embodiment 1, and the present invention also can change the focal length of all microlenses with the same size simultaneously by all micromirrors all moving the same size distance at the same time, as image 3 shown. The microlens array is a refractive microlens array.

Embodiment 3

[0035] Other content is as content in embodiment 1, and the present invention also can change the focal length of all microlenses with the same size simultaneously by all micromirrors all moving the same size distance at the same time, as image 3 shown. The microlens array can also be a diffractive microlens array to accomplish the same function, such as Figure 6 shown. Refractive microlenses and diffractive microlenses have their own advantages and disadvantages, and can be selected according to different situations and application fields.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com