Pearly mask and preparation method thereof

A pearlescent and facial mask technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of poor thickness uniformity, poor printing performance, unreliable process, etc., and achieve good dimensional stability, good printing performance, good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

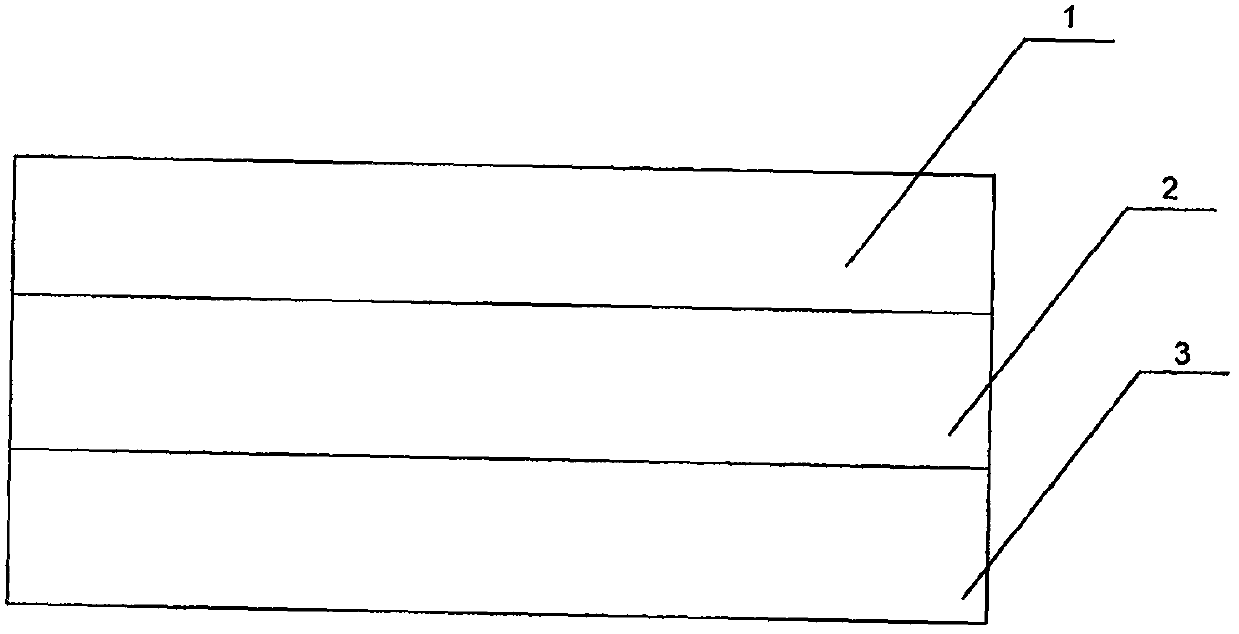

Image

Examples

Embodiment approach

[0023] As a preferred embodiment of the present invention, the longitudinal stretching comprises the following steps: the mask sheet is heated to the stretching temperature on a preheating roller; the mask sheet is stretched longitudinally on at least two sets of stretching rollers, and The diameter of the stretching roller is small, and the stretching gap can be adjusted within a certain range, which can reduce the necking of the sheet; in order to avoid excessive shrinkage of the product during storage, the mask sheet is shaped on the heat setting roller after longitudinal stretching . During longitudinal stretching, the rotational speed of each roller must be kept constant. The longitudinal stretching system consists of many rollers. It is troublesome and unsafe to thread the film manually. Generally, the sheet threading system is used.

[0024]As a preferred embodiment of the present invention, the transverse stretching includes the following steps: first, heat in an air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com