Automatic correcting-recovering equipment for U-shaped steel plate for water-conservation lake flood control dam

A technology of steel sheet piles and lakes, applied in metal processing equipment, forming tools, feeding devices, etc., can solve problems such as low work efficiency, time-consuming and laborious, and inaccurate fixed-point repair of steel sheet piles, so as to reduce labor intensity and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

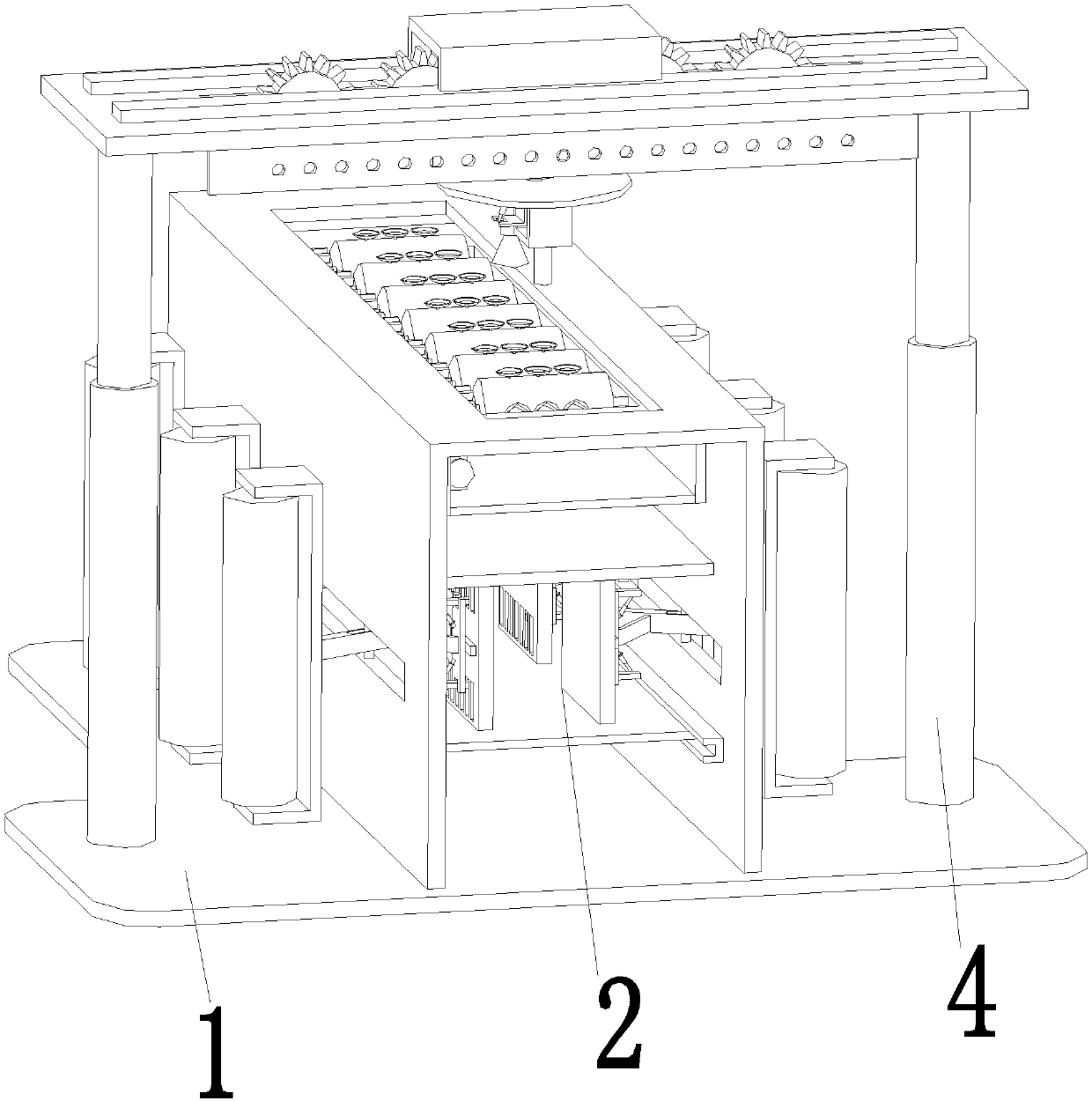

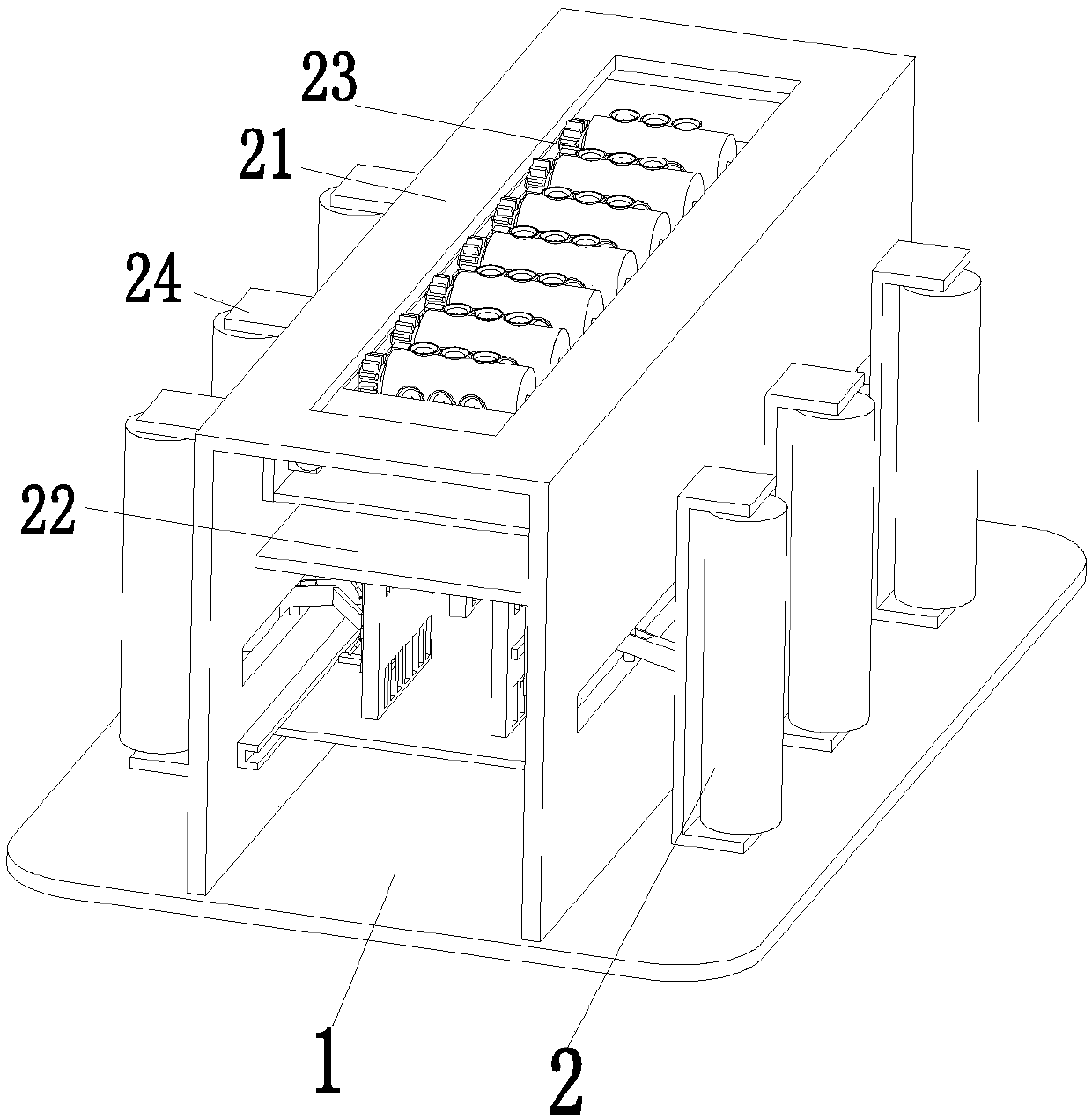

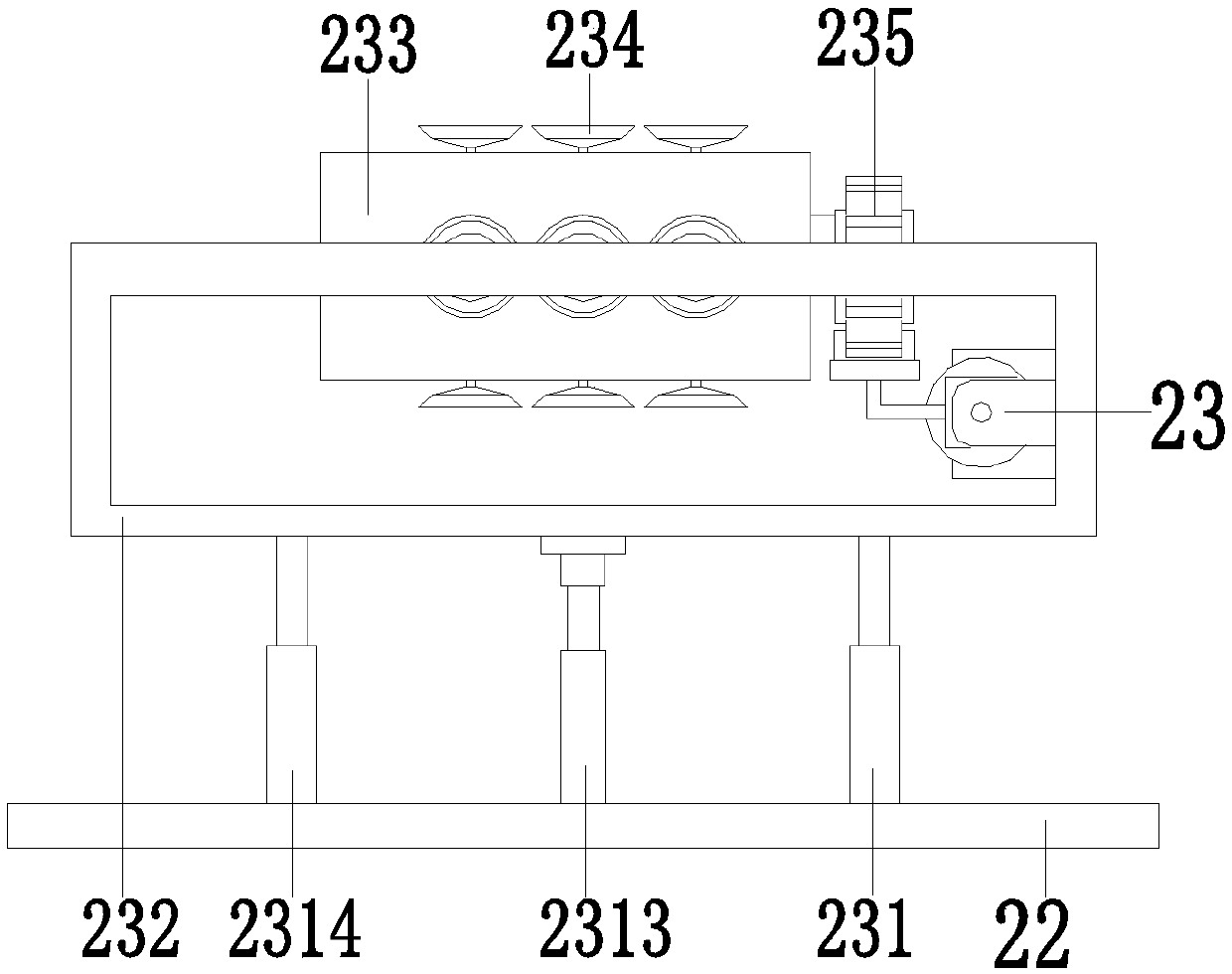

[0029] Such as Figure 1 to Figure 8 As shown, a U-shaped steel sheet pile automatic rectification and restoration equipment for water conservancy lakes and flood control dams includes a bottom plate 1, a fixed conveying device 2 is installed in the middle of the upper end of the bottom plate 1, a baking straightening device 4 is installed on the bottom plate 1, and the baking straightening device 4. It is located directly above the fixed conveying device 2. The fixed conveying device 2 can convey and fix the steel sheet piles that need to be repaired. The baking correction device 4 can correct the deformed position of the steel sheet pile surface. The fixed conveying device 2 and the baking The correcting devices 4 are used in conjunction with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com