Precise temperature control method for oil source of ultra precision machine tool pump station

An ultra-precision machine tool and oil source technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of inability to realize precise control of oil source temperature, temperature fluctuation of refrigerator, unfavorable system stability, etc. , to achieve the effect of stabilizing temperature fluctuations, reducing temperature overshoot, and avoiding frequent start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

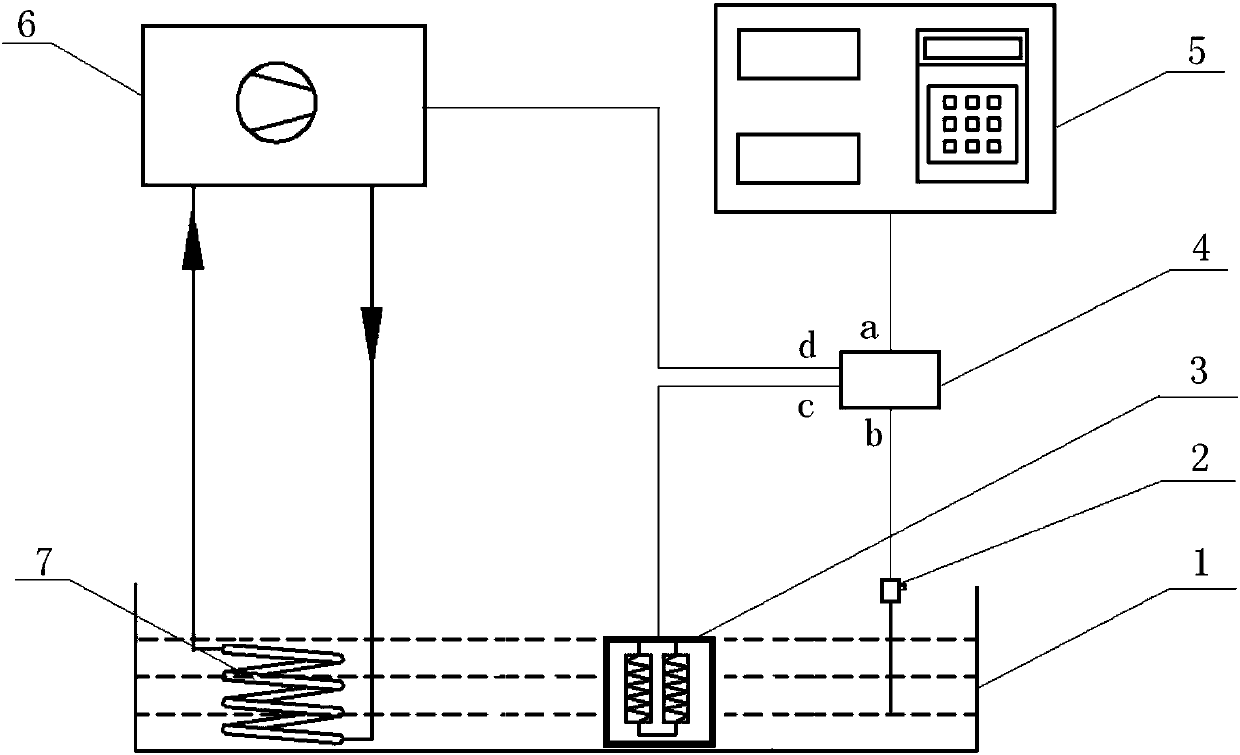

[0028] 1. Set the oil source temperature of the fuel tank: according to the processing accuracy requirements of the ultra-precision machine tool, set the preset value of the oil source temperature through the controller 5 to 20°C;

[0029] 2. Oil source temperature detection of the fuel tank: the temperature sensor 2 detects that the actual value of the oil source temperature of the fuel tank is 21°C, and the controller 5 compares the actual value with the preset value, and obtains the difference between the actual value minus the preset value as 1°C, according to the difference, the current state of the oil source temperature of the fuel tank is determined to be an overheated state;

[0030] 3. Control the oil source temperature of the fuel tank: At this time, the oil source temperature of the fuel tank is in an overheated state. The controller 5 starts the refrigeration unit 6 through the temperature control unit 4 to cool the oil source temperature of the fuel tank. When it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com