Method for purifying cephalosporin C fermentation broth

A cephalosporin and fermentation liquid technology, applied in organic chemistry and other directions, can solve the problems of separation and purification process influence, high labor intensity, harsh labor environment, etc., and achieve the effect of improving the quality of feed liquid, low labor intensity, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

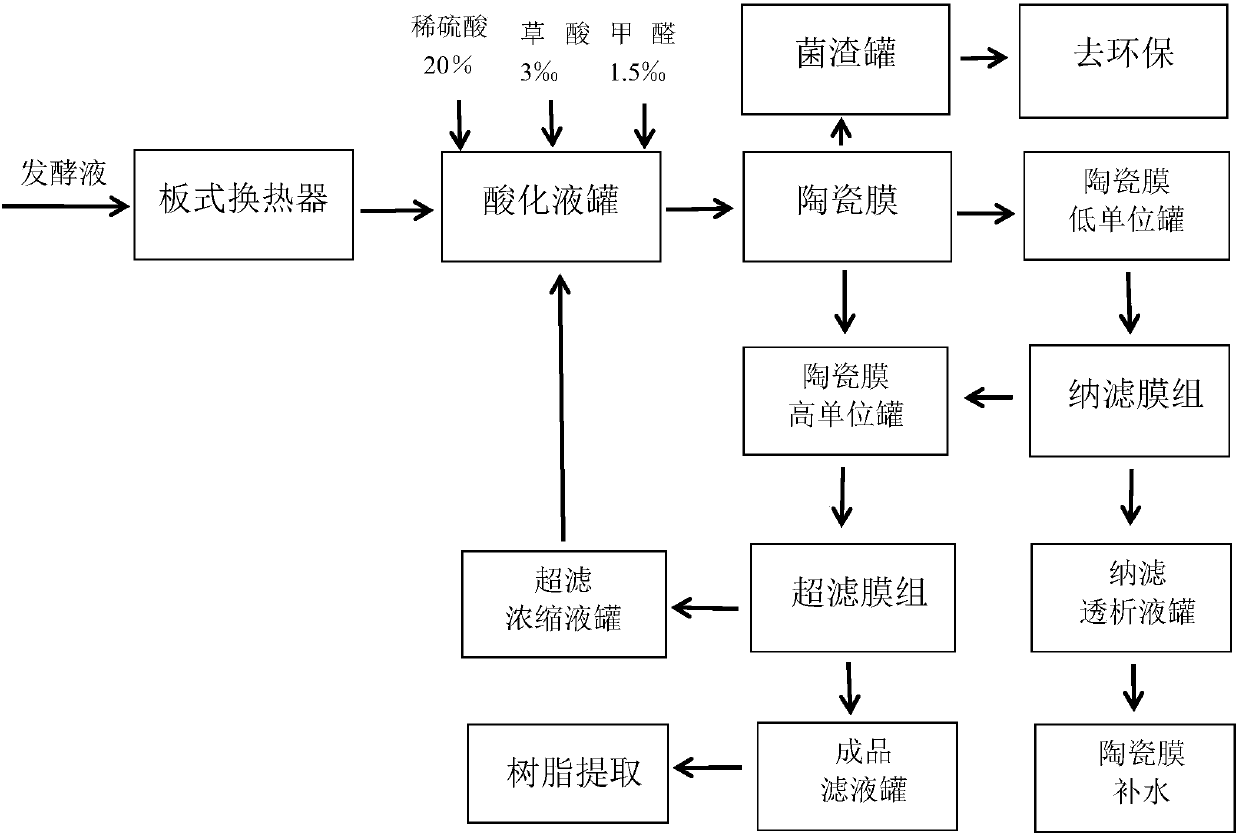

Method used

Image

Examples

preparation example Construction

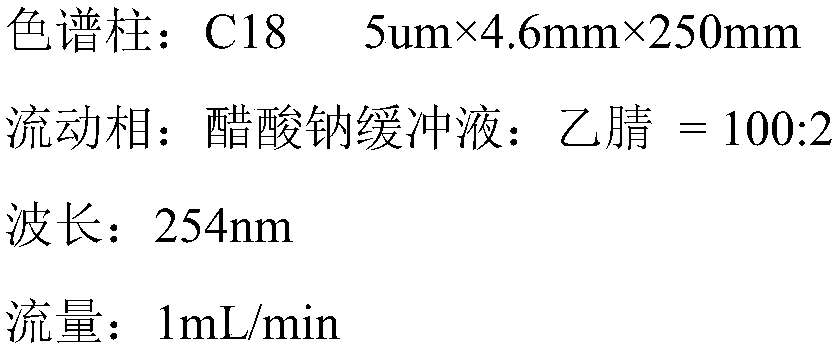

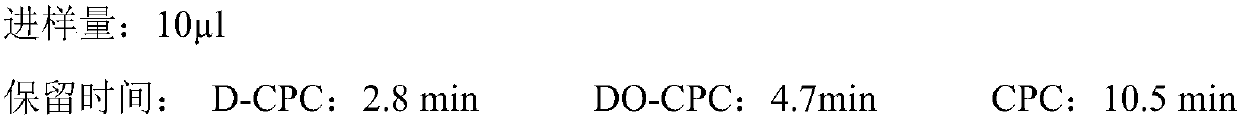

[0035] a. Preparation of reference substance:

[0036] Accurately weighed (24-26 mg) CPC sodium salt reference substance, add an appropriate amount of pH 4.75 sodium acetate buffer solution, dissolve it with ultrasonic waves, transfer it to a 100mL volumetric flask after dissolving, adjust the volume to the mark with buffer solution, and shake well. The preparation of the reference substance should be weighed in duplicate, and the relative average deviation of the response factors after the injection of the two reference substances should be less than 0.5%.

[0037] b. Preparation of sample solution:

[0038] Dilute the original sample solution with sodium acetate buffer solution according to the required dilution factor, so that the diluted concentration is about 200 titer units per milliliter, filter it into the injection vial with a 0.22um disposable needle filter and wait for injection .

[0039] c. Preparation of fermentation broth and acidification solution

[0040] A...

Embodiment 1

[0061] Embodiment 1 The method of the present invention

[0062] The fermentation liquid enters four 160m 3 For the acidification tank, when the liquid level of the acidification tank reaches 30%, the tank is turned on for stirring, and at the same time, the circulating water at -10°C is turned on to keep the temperature of the feed liquid from rising. When the liquid level of the acidification tank reaches 50%, slowly add 3‰ (w / w) oxalic acid, add 20% dilute sulfuric acid to adjust the pH to 3.0-3.2, add 1.5‰ (v / v) formaldehyde, after stirring evenly, Drive into the vibrating sieve through the acidification pump and enter the ceramic membrane raw material tank. When the volume in the tank reaches 30%, turn on the circulating water at -10°C in the tank to keep the temperature of the material liquid from rising. Wait until the liquid level reaches 50m 3When the ceramic membrane raw material pump enters the right-angle filter before the membrane, it enters the ceramic membrane...

Embodiment 2

[0066] Embodiment 2 The method of the present invention

[0067] The fermentation broth enters four 160m 3 For the acidification tank, when the liquid level of the acidification tank reaches 30%, the tank is turned on for stirring, and at the same time, the circulating water at -10°C is turned on to keep the temperature of the feed liquid from rising. When the liquid level of the acidification tank reaches 50%, slowly add 3‰ oxalic acid, add 20% dilute sulfuric acid to adjust the pH to 2.8-3.0, add 1-4‰ formaldehyde, and after stirring evenly, pour it into the vibrating screen through the acidification pump. Enter the ceramic membrane raw material tank, and when the volume in the tank reaches 30%, turn on the circulating water at -10°C in the tank to keep the temperature of the feed liquid from rising. Wait until the liquid level reaches 50m 3 At the same time, the ceramic membrane raw material pump is pumped into the right-angle filter before the membrane, and then enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com