Fast constructed three-span continuous space special-shaped cable-stayed combined bridge and construction method

A continuous and spatial technology, applied in cable-stayed bridges, bridges, bridge forms, etc., can solve problems such as difficult construction control, increased tower bottom bending moment, and large change in cable force amplitude of stay cables, and achieves easy manufacturing quality. Control, increase strength and toughness, effect with little influence of surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

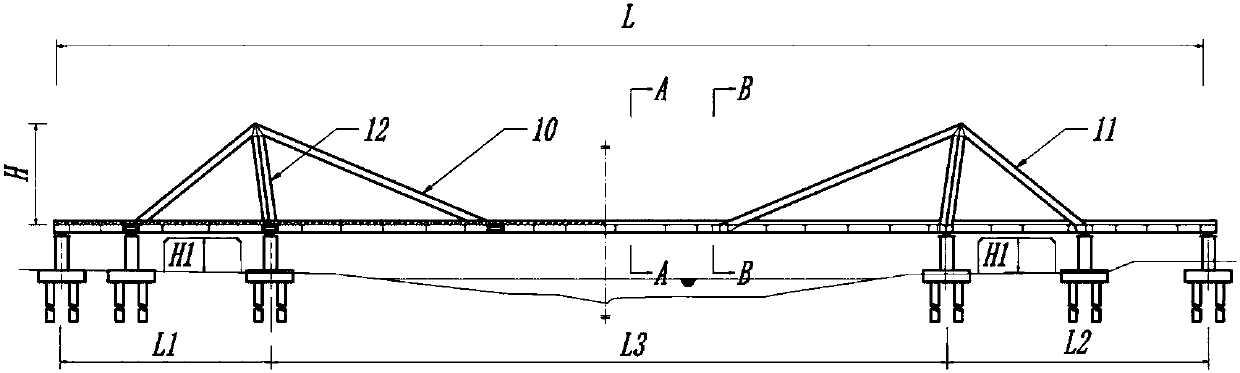

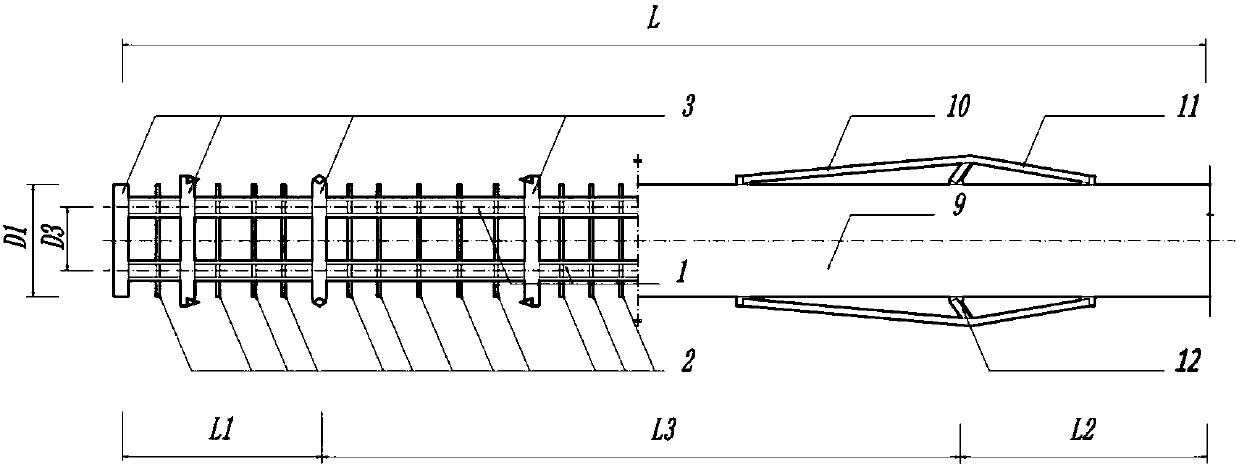

[0070] Such as figure 1 , 2 As shown, the total span L of the bridge is 150m, the side span L1 is 25m, the side span L2 is 35m, the main span L3 is 90m, the bridge deck width D is 15m, and the tower height is 13.5m. sides. There are riverside roads on both sides of the river bank, and the clearance H1 above the roads is guaranteed to be 5m. The bridge adopts 2 longitudinal girders, 8 transverse box girders, 25 diaphragm girders, 4 mid-span tie rods, 4 side-span tie rods and 4 bridge towers. The layout is as follows: figure 1 , 2 .

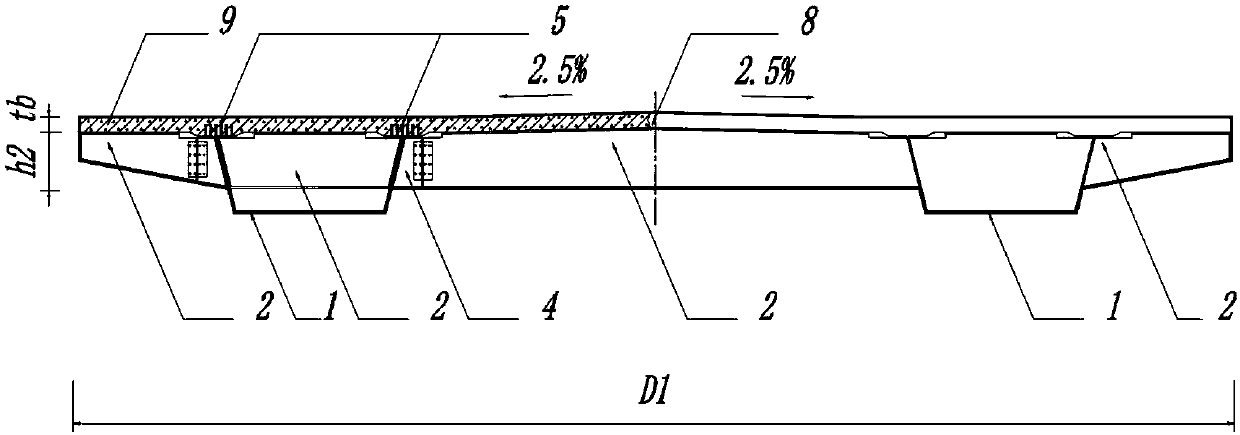

[0071] Stringer ( Figure 9 ) presents a trapezoid with a wide top and a narrow bottom, and the distance D3 between two longitudinal beams is 9m. The upper width l1 of each longitudinal girder is 2.5m, the lower width l2 is 2m, and the girder height h1 is 1m. The thickness of the web and bottom plate varies along the length of the bridge. A group of studs are welded at certain intervals to connect the bridge deck and longitudinal girders.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com