Composite of multilayer structure comprising polyester foam and polyester resin layer, and use thereof

A technology of polyester resin and compound, which is applied in the field of compound with multi-layer structure, can solve the problems of high melt viscosity, difficult to collect bubbles, low foaming rate, etc., and achieve the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

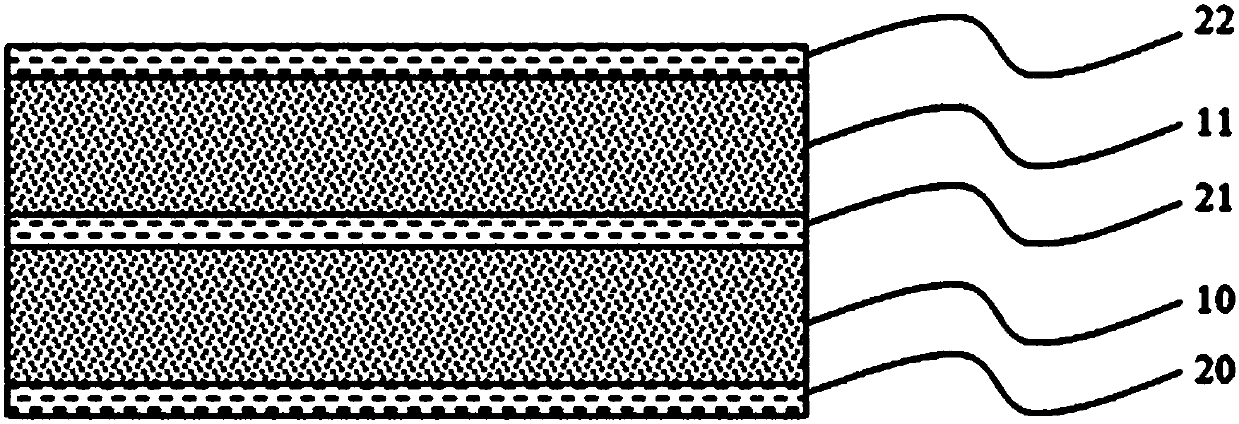

[0107] Embodiment 1: the preparation of polyester compound

[0108] In order to prepare the polyester compound according to the invention,

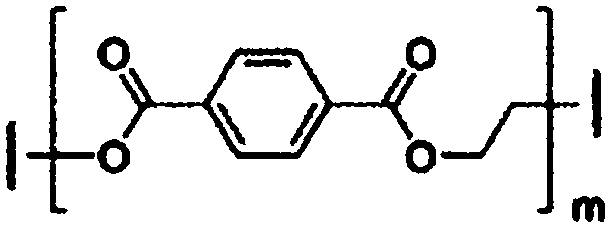

[0109] (1) First, 100 parts by weight of PET resin was dried at 130° C. to remove moisture. In the first extruder, PET resin from which moisture was removed, 1 part by weight of pyromellitic dianhydride (PMDA), 1 part by weight of talc, and 0.1 part by weight of Irganox (IRG 1010) were mixed and heated to 280°C to prepare a resin melt . Next, carbon dioxide gas was mixed as a foaming agent in the first extruder, and the resin melt was sent to the second extruder and cooled to 220°C. The cooled resin melt is extruded and expanded through a die, whereby a polyester foam is produced.

[0110] (2) Then, under the conditions of a pressure of 3kgf and a temperature of 250°C, a biaxially stretched film with a longitudinal elongation of 3 times, a transverse elongation of 1.5 times, and a thickness of 150 μm is foamed in polyester. The interf...

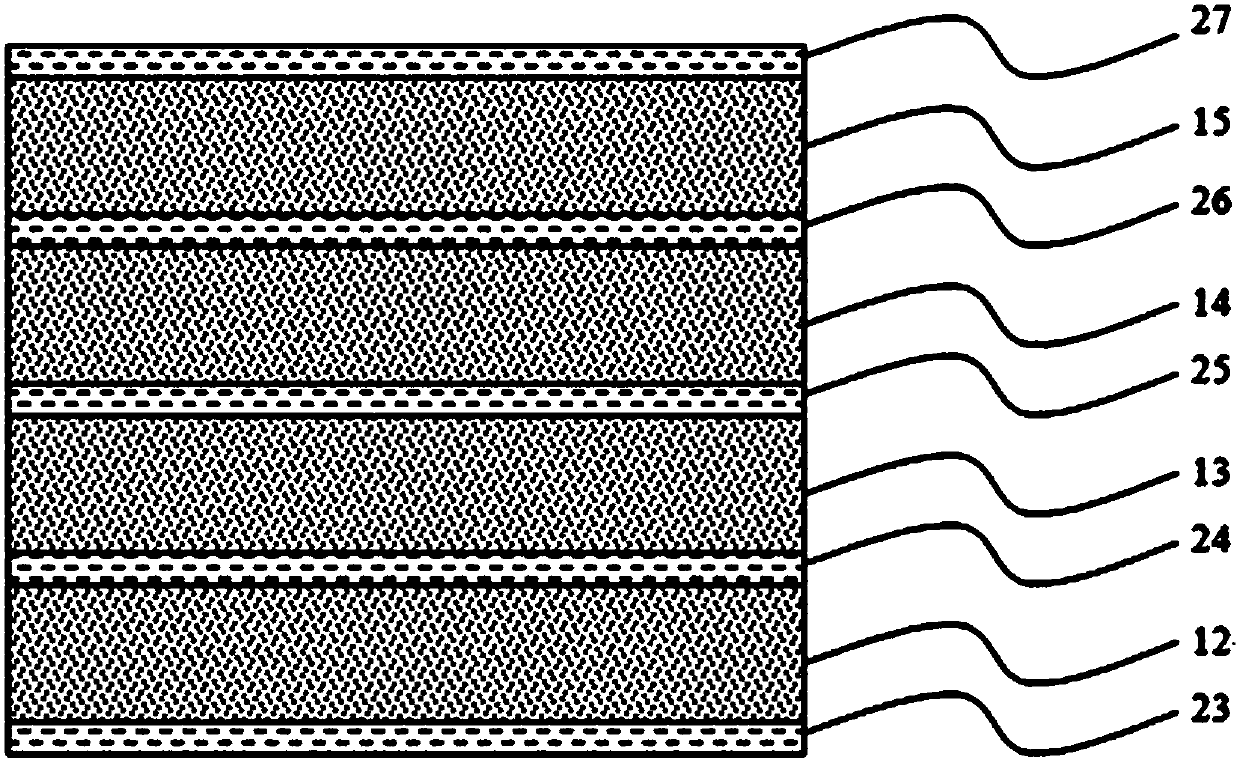

Embodiment 2

[0114] Embodiment 2: the preparation of polyester compound

[0115] A polyester composite was prepared in the same manner as in Example 1, except that 0.2 parts by weight of graphite was mixed based on 100 parts by weight of the resin when preparing the PET resin layer.

Embodiment 3

[0116] Embodiment 3: the preparation of polyester compound

[0117] A polyester compound was prepared in the same manner as in Example 1 except that a PET adhesive layer was formed between the PET foam and the PET resin layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com