Indirect heating carbonization system

A technology of carbonization treatment and heating method, which is applied in the field of carbonization treatment system of indirect heating method, can solve problems such as heavy burden, and achieve the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

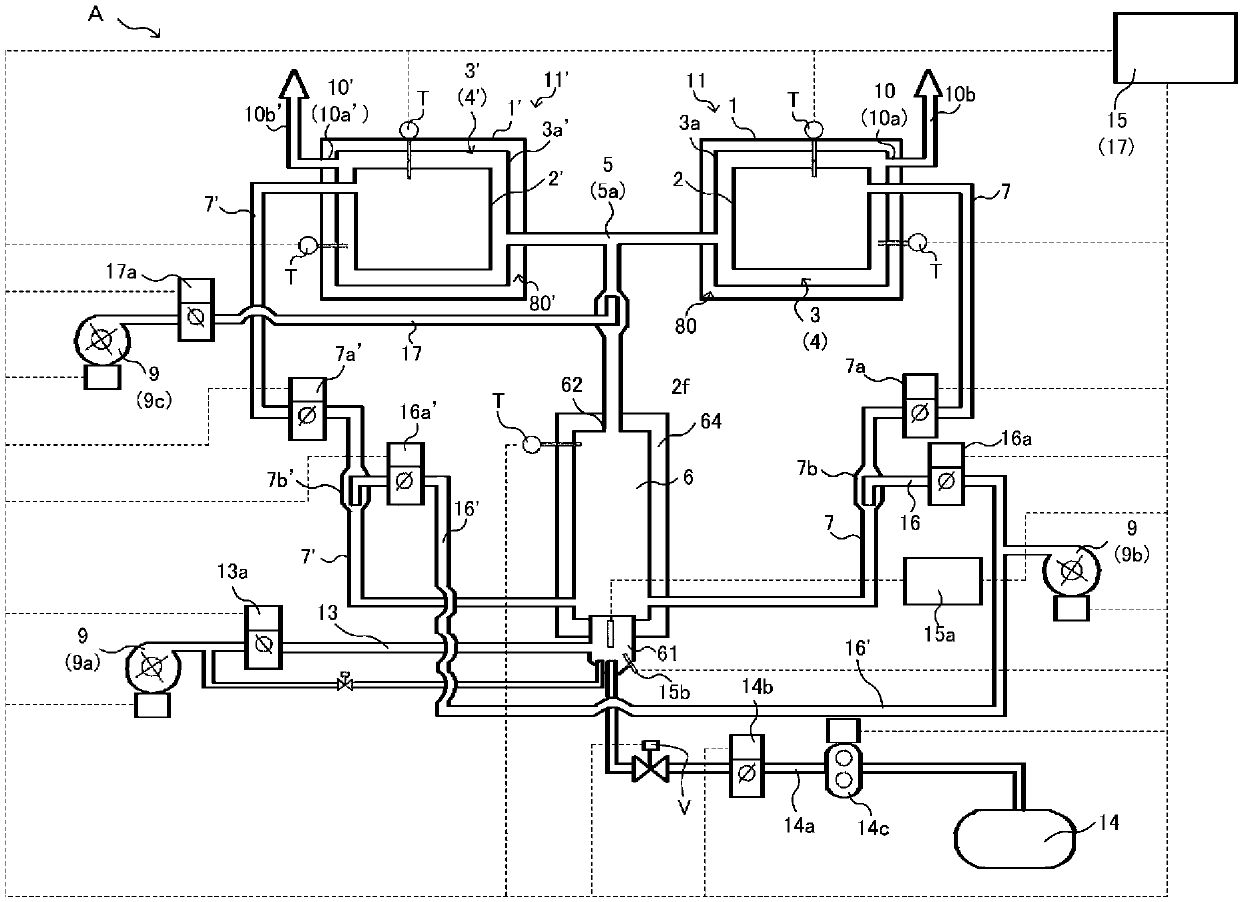

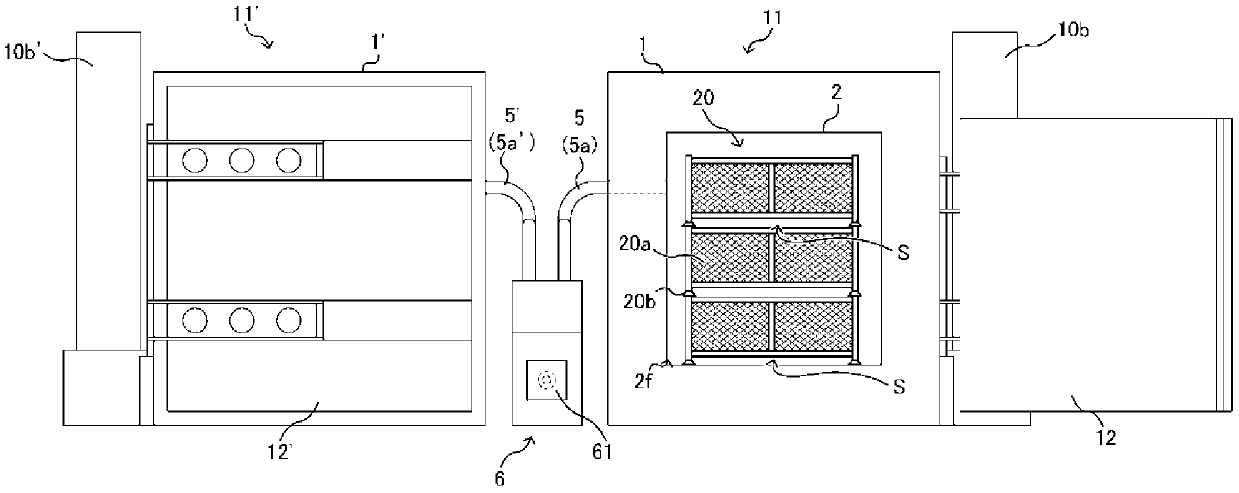

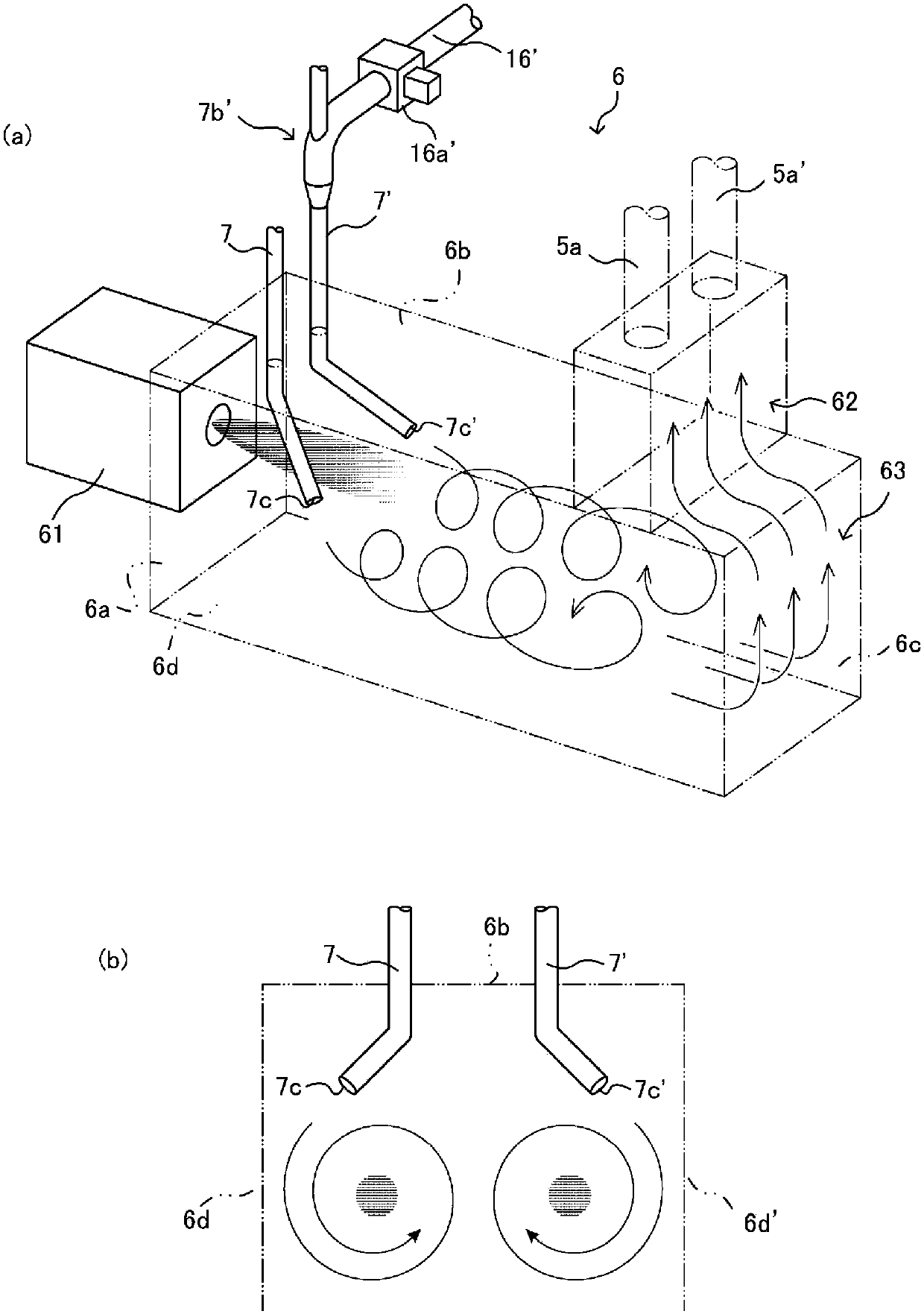

[0036] Hereinafter, an indirect heating system carbonization treatment system A (hereinafter, simply referred to as carbonization treatment system A) according to an embodiment will be described with reference to the drawings. figure 1 It is an explanatory diagram showing the concept of the overall structure of the carbonization treatment system A. also, figure 2 It is a front view showing the appearance of the carbonization treatment system A. Figure 4 It is a perspective view when the structure of the heat flow path 4 surrounding the carbonization chamber 2 is seen from the upper side of one side.

[0037] like figure 1 and figure 2 As shown, the carbonization treatment system A involved in the present invention is equipped with: a combustion chamber 6 that generates hot air in its central part; and a heat flow path layer 3, 3' that circulates hot air on both ends of the combustion chamber 6. The two carbonization chambers 2, 2' on the periphery other than the front m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com