Seedling pushing and inclined cutting type pot clamping and seedling picking end actuating device and method

An end-effector and oblique inserting technology, applied in the field of agricultural machinery, can solve the problems of unavoidable damage to seedlings, large plant height, pinching off the stems of seedlings, etc., and achieves the effect of avoiding needles to pick up damaged seedlings and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

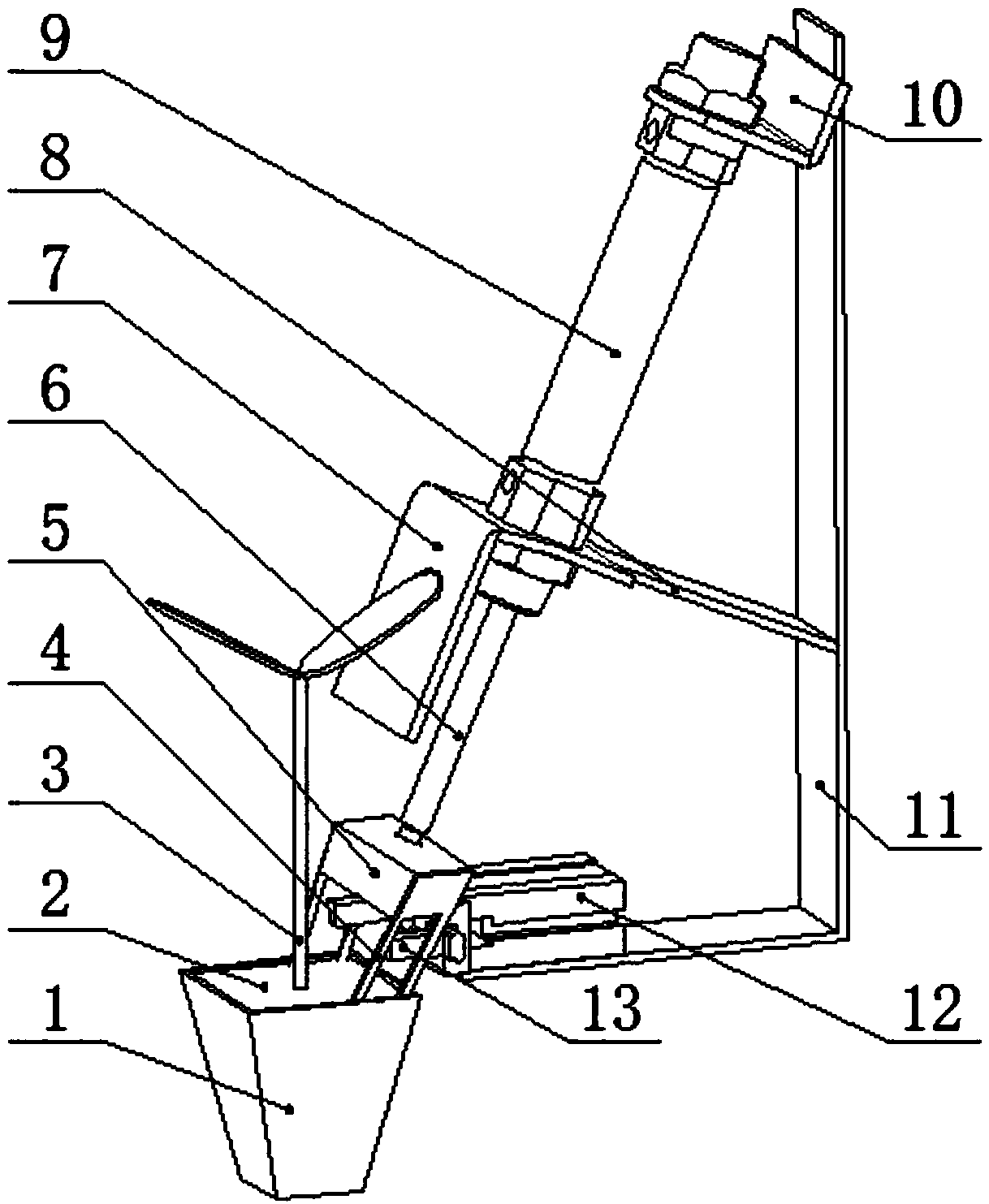

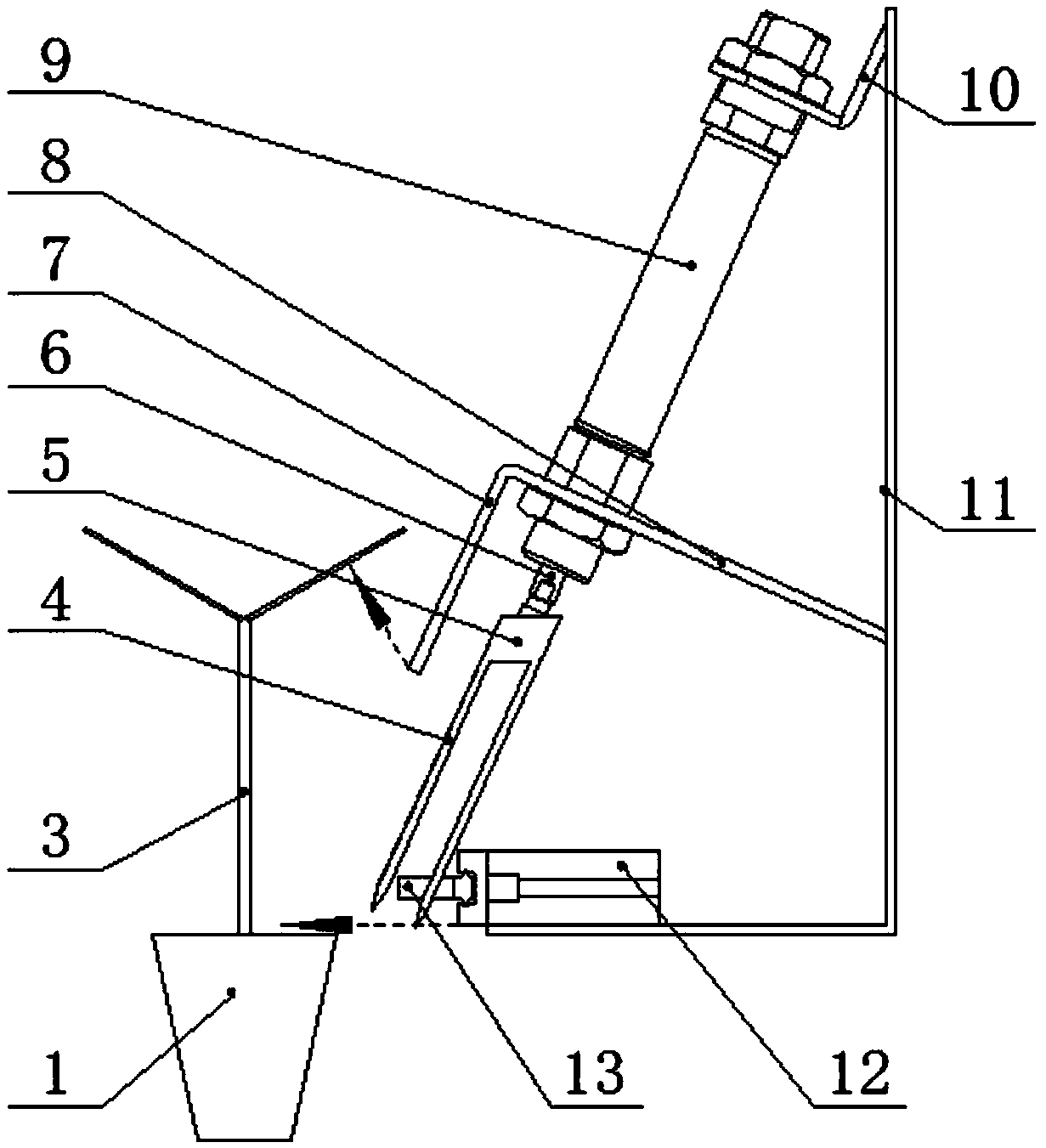

[0037] figure 1 Shown is an embodiment of the end effector for pushing seedlings obliquely inserted into a pot for seedling retrieval. The end effector for pushing seedlings obliquely inserted into a pot for seedling retrieval includes a seedling pushing obliquely inserted unit, a parallel opening and closing unit and and control unit.

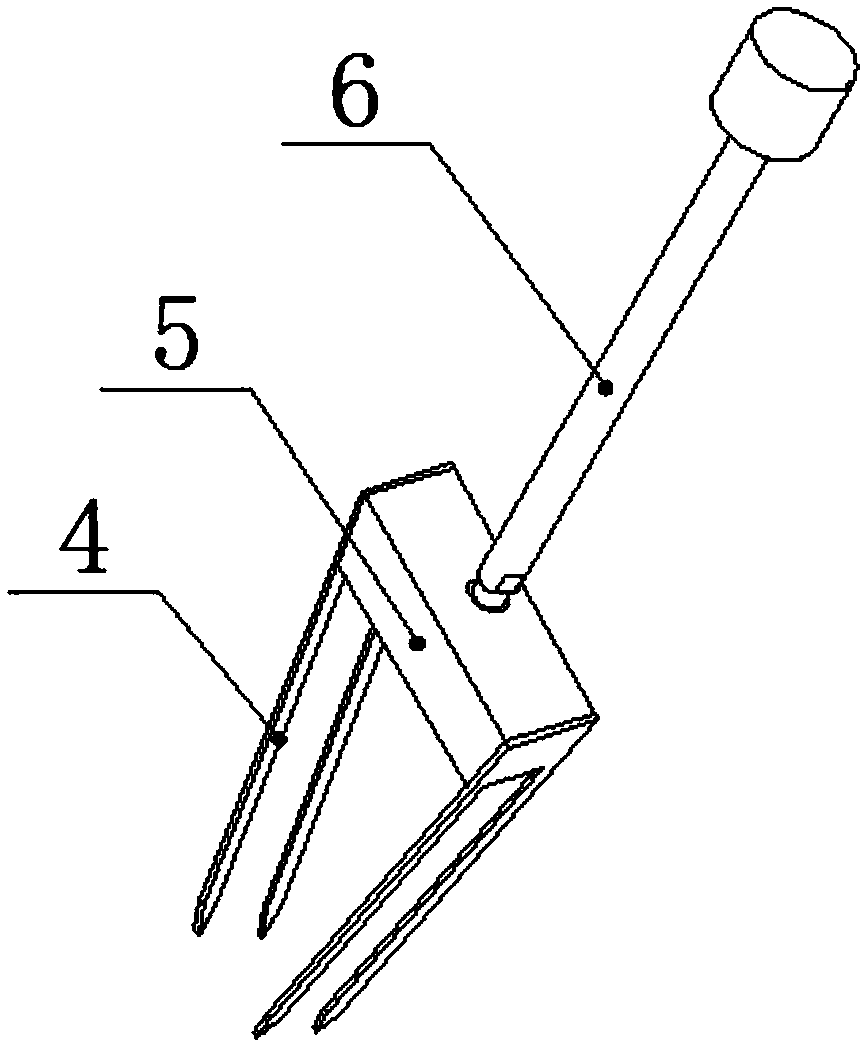

[0038] The oblique insertion unit for pushing seedlings is obliquely fastened on the bracket 11, and includes a clamping needle 4, a tapered block 5, a telescopic rod 6, a seedling pushing plate 7, a support plate 8, a direct-acting telescopic mechanism 9 and a tailstock 10; figure 2 As shown, the clamping needle 4 is fork-shaped, symmetrically arranged on both sides of the conical block 5, the conical block 5 is locked and connected to the end of the telescopic rod 6, and the other end of the telescopic rod 6 Fastened on the telescopic rod of the direct-acting telescopic mechanism 9, the described seedling pushing plate 7 is facing the seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com