A kind of natural concentrated dietary fiber and its preparation method

A dietary fiber, natural technology, applied in the direction of bacteria, food processing, food science, etc. used in food preparation, can solve the problems of high insoluble fiber content, poor feed palatability, low fiber content, etc., to reduce production costs and acid production. The effect of high capacity and low enzyme dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

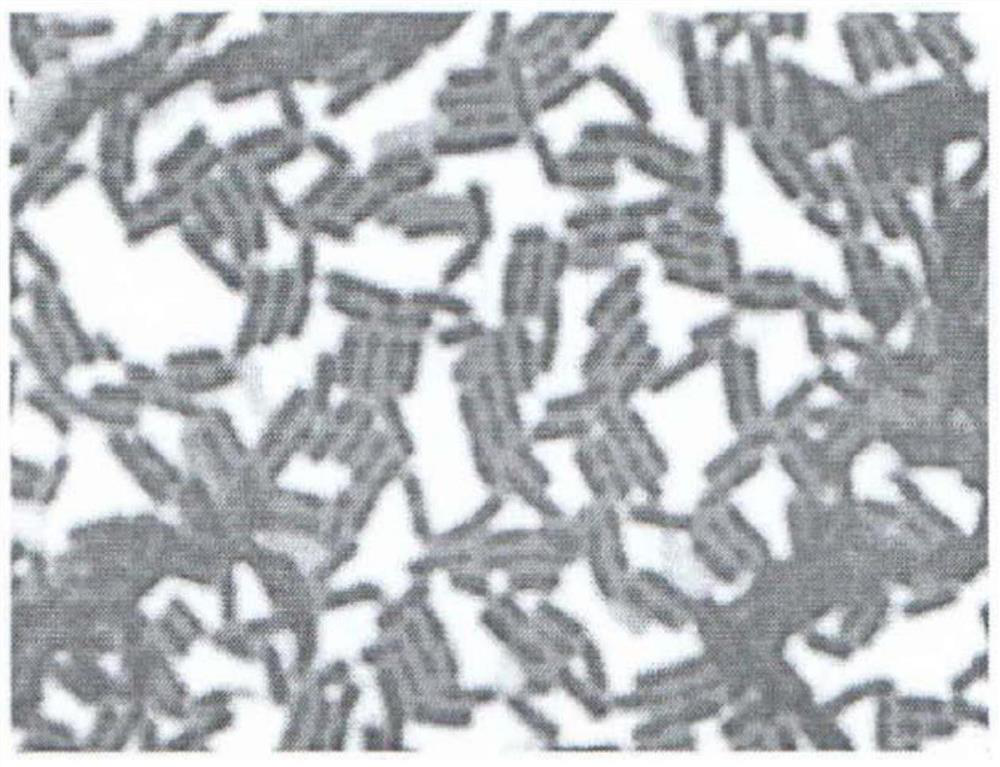

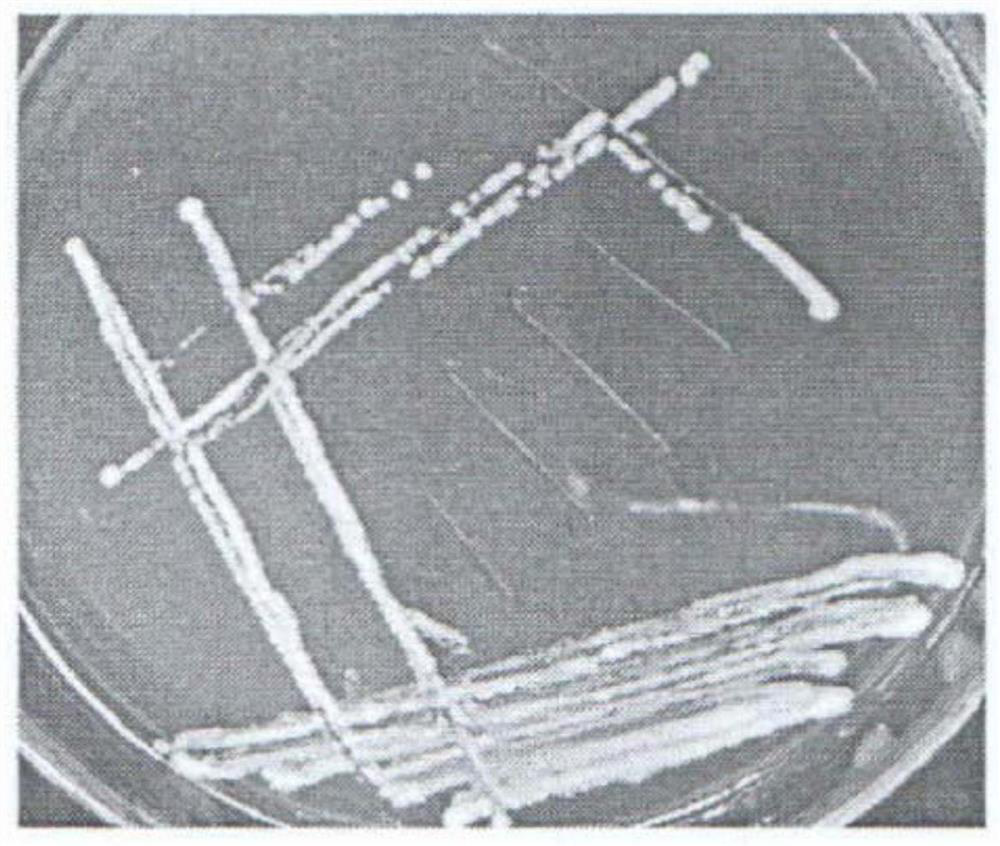

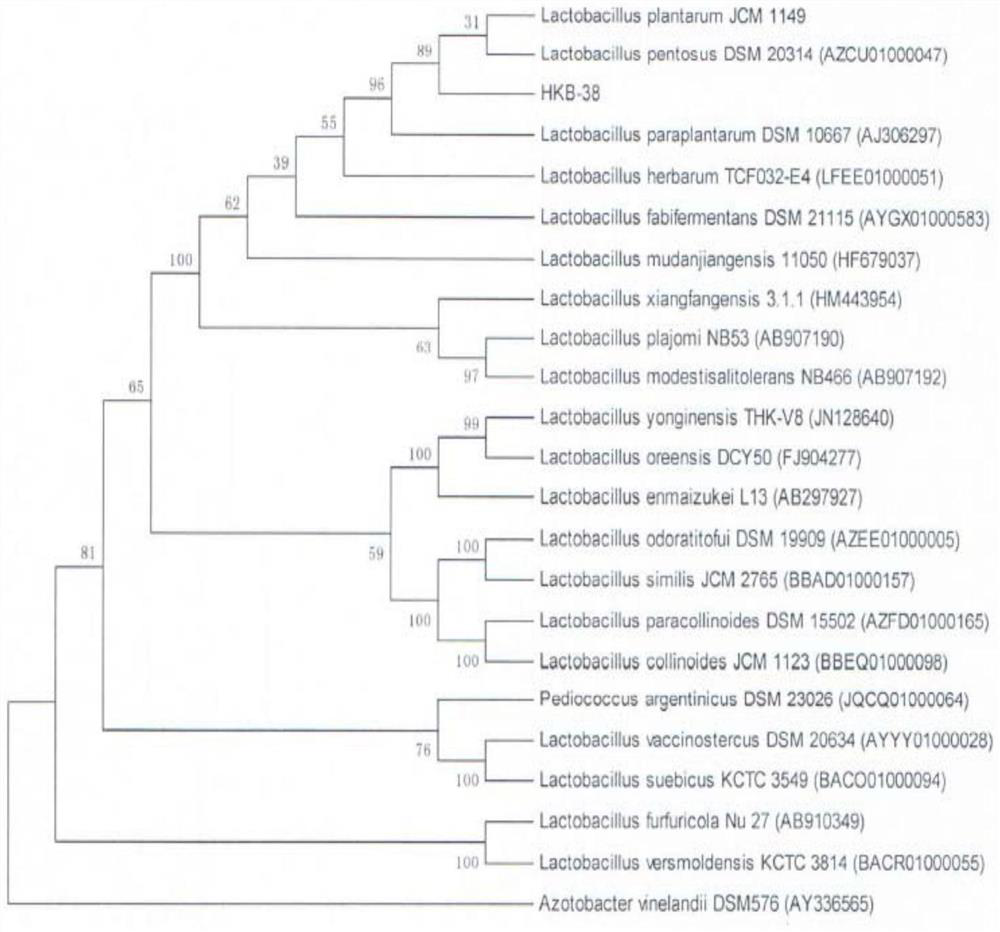

[0029] Example 1: Isolation and identification of a strain of Lactobacillus plantarum

[0030] 1. Take healthy piglet small intestine (such as duodenum, jejunum, ileum, cecum, colon) intestinal mucosa 5cm 2 , put it in a sterilized beaker, wash the contents on the mucosa with sterile saline, immerse the mucosa in a beaker filled with 15mL of HEPES buffer, shake the mucosa back and forth with tweezers for 5min, and draw 0.2mL of the supernatant with a sterile syringe Put the liquid into the Hungates rolling tube with Rogosa SL agar, roll it gently by hand to make the supernatant evenly distributed on the surface of the agar in the tube, put in 5% CO 2Incubator, after incubating at 37°C for 72 hours, perform aseptic operation in a biological safety cabinet, use a needle to pick up white needle-sized colonies into anaerobic sterile Rogosa broth for cultivation, observe whether the broth becomes turbid, and select well-growing, If there is turbidity, store in a 4°C refrigerator f...

Embodiment 2

[0043] Example 2: Effect of different pine bark raw materials on natural concentrated dietary fiber

[0044] 1) After cleaning and removing impurities from the bark of Yunnan pine, larch and masson pine, crush them through a 20-mesh sieve, add room temperature water to soak, the ratio of crushed raw materials to room temperature water is 1g: 10mL, soaking time is 4h , to discharge the waste water.

[0045] 2) Transfer the three kinds of pine bark raw materials obtained in step 1) to the reactor respectively, add water again, the ratio of pine bark raw material to normal temperature water is 1g:20mL, and carry out ultrasonic-assisted enzymolysis, which is specifically after ultrasonic pretreatment for 5 minutes , adding 1g enzyme activity in every liter of mixed solution is the pectinase of 1.0U / mg (the product number that U.S. Sigma company sells is the pectinase of 17389) and 5g enzyme activity is the papain (the U.S. Sigma company sells) of 12U / mg The product number is 7621...

Embodiment 3

[0051] Example 3: Effects of Fermentation of Different Probiotics on Natural Concentrated Dietary Fiber

[0052] 1) After cleaning and removing impurities from the bark of pine yunnanensis, crush it through a 30-mesh sieve, add room temperature water to soak, the ratio of crushed raw material to room temperature water is 1g:5mL, soak for 2 hours, and drain the waste water.

[0053] 2) Transfer the pine bark raw material obtained in step 1) to the reactor, add water again, the ratio of pine bark raw material to normal temperature water is 1g: 10mL, and carry out ultrasonic-assisted enzymolysis, which is specifically after ultrasonic pretreatment for 10 minutes. Adding 1.2g enzyme activity is the pectinase of 1.0U / mg (the product number sold by U.S. Sigma company is the pectinase of 17389) and 6g enzyme activity is the papain (the product sold by U.S. Sigma company) of 12U / mg No. 76218 papain) for enzymolysis, the enzymolysis temperature is 55°C, the enzymolysis pH value is 6.0,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| swelling | aaaaa | aaaaa |

| swelling | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com