Manufacturing method of animal hoof trimming machine

A production method and hoof technology, applied in the field of sheep hoof repairing machinery in sheep and poultry farms, can solve the problems of high labor intensity, inconvenient feeding, and inconvenient walking, and achieve the effect of convenient operation, simple structure, and easy pruning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

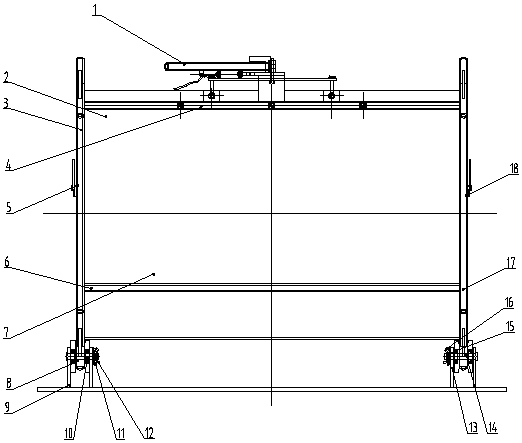

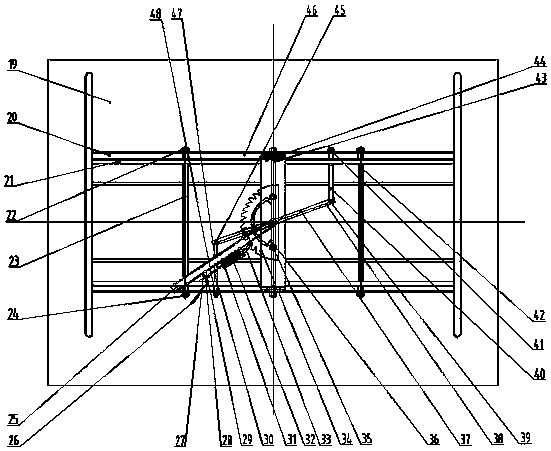

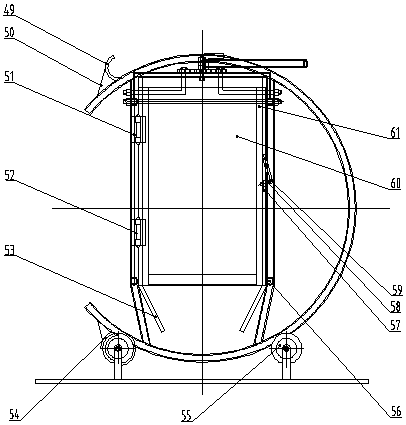

[0018] Such as figure 1 , figure 2 , image 3 As shown, the manufacturing method of the animal hoof trimming machine is characterized by: a fastening mechanism 1, a support frame 2, a roller structure 8, a lower fixed plate mechanism 19, a baffle mechanism 46, a front and rear door structure 60 and other structures. . The fastening mechanism 1 is arranged in the middle part of the upper end of the sheep's hoof repairing machine, and consists of an adjustment lever handle 25, an adjustment handle 26, a U-shaped connecting plate 27, a pin shaft 28, a split pin 29, a connecting wire 30, a fixing sleeve 31, a spring 32, and an adjustment Pin shaft 33, semicircular tooth type limit plate 34, fixing bolt 35, limit rod 36, lever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com