Grading treatment circulating system for producing ground calcium carbonate

A heavy calcium carbonate, graded treatment technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., to achieve the effects of reducing the generation of fine particles, uniform distribution, and narrowing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to embodiments and drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

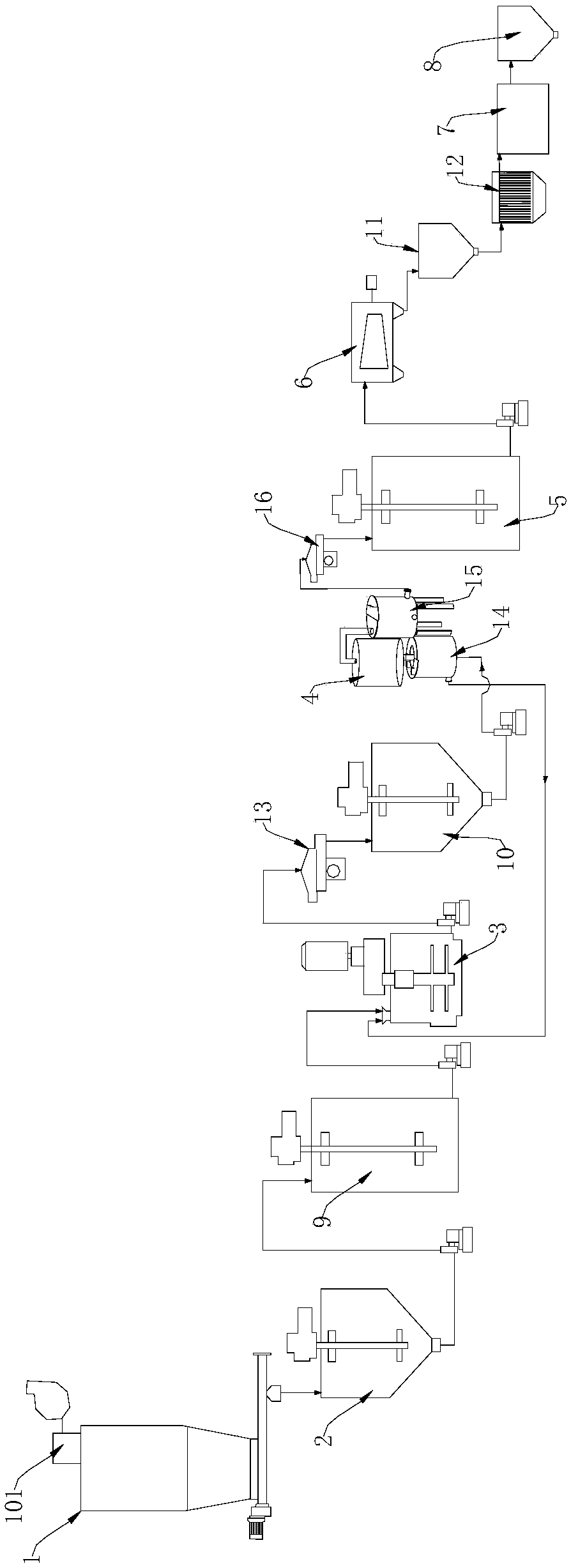

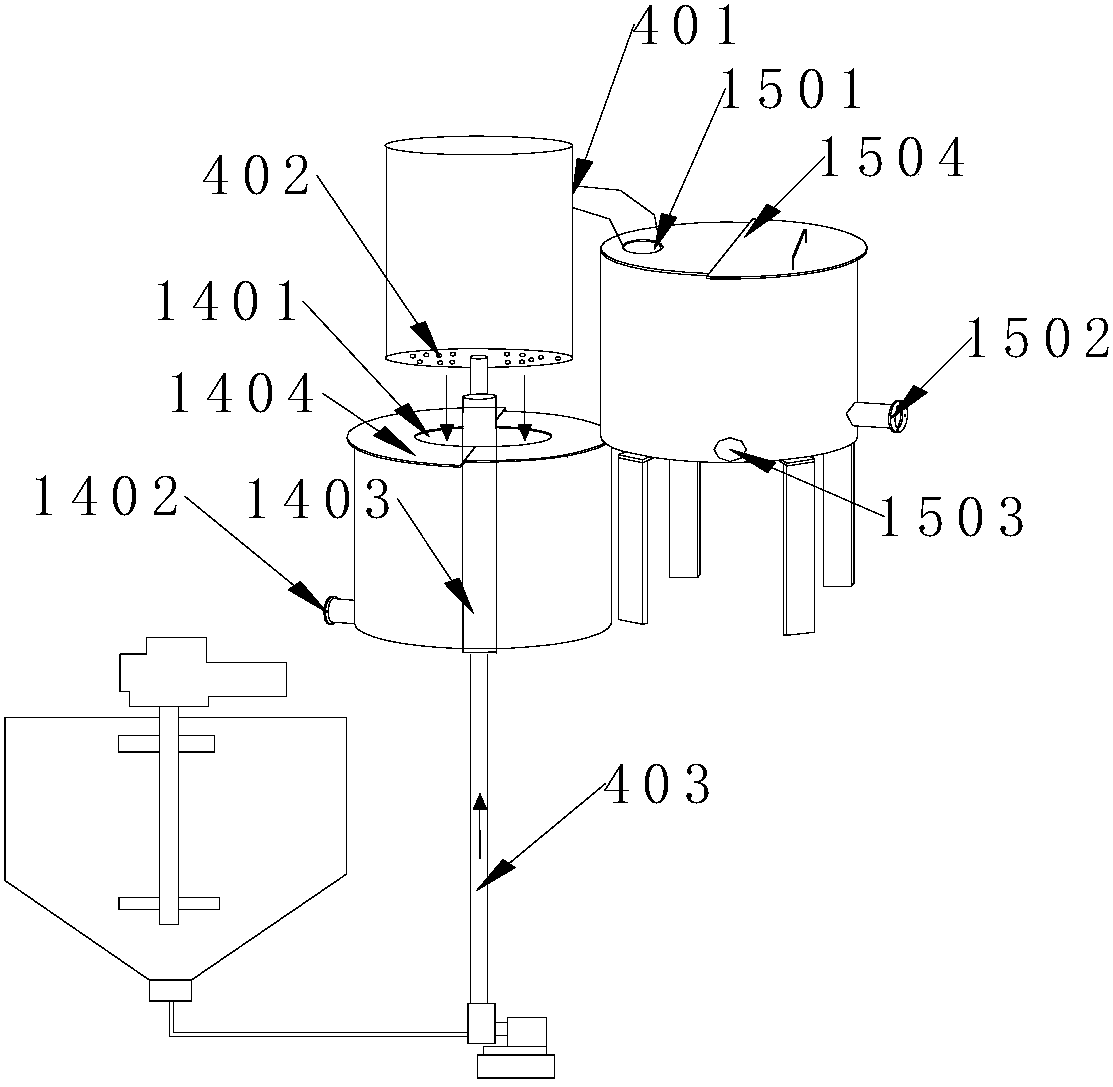

[0031] Such as figure 1 with figure 2 As shown together, a classification treatment cycle system for the production of heavy calcium carbonate and a classification treatment cycle system for the production of heavy calcium carbonate are arranged in sequence according to the direction of the raw materials with a raw material tank 1, a batching tank 2, a wet mill 3, and a cyclone Device 4, finished slurry tank 5, centrifuge 6, dryer 7 and finished product tank 8.

[0032] The raw material tank 1 is connected to the batching tank 2 through a screw conveyor, a wet mill buffer tank 9 is also arranged between the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com