Automatic cleaning device for piston rod of shock absorber

An automatic cleaning and piston rod technology, applied in the directions of dry gas arrangement, chemical instruments and methods, cleaning methods and utensils, etc., can solve the complex internal structure of the shock absorber core, affect the cleanliness of the shock absorber package, and affect the product. Quality accident rate and other issues, to achieve the effect of saving manpower, occupying less space, and preventing water pump failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

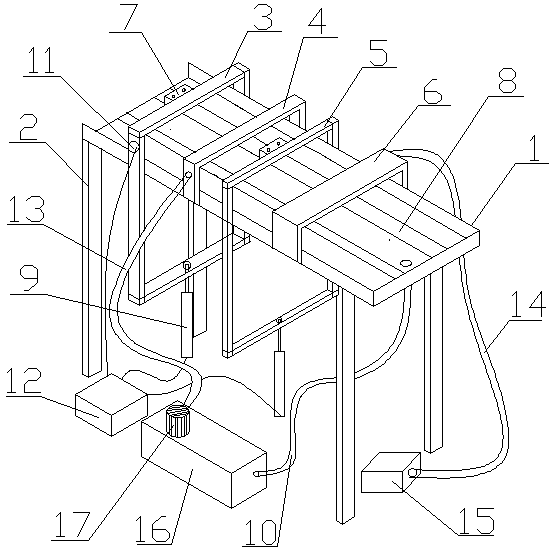

[0022] Such as figure 1 As shown, a shock absorber piston rod automatic cleaning device, the tank body 1 is arranged obliquely on a plurality of support columns 2, the first buffer frame 3, the spray device 4, the second Buffer block frame 5 and blowing device 6, on described first buffer block frame 3 and described second buffer block frame 5 all be provided with stopper 7, in described groove body 1, two horizontal bars 8 are suspended in the air, and described groove An electric push rod 9 supporting the buffer frame is arranged under the body 1, a drain hole is arranged on the bottom surface of the tank body 1, and a drain pipe 10 is connected to the drain hole, and a moving sensor 11 is arranged on the first buffer frame 3 , the motion sensor 11 and the electric push rod 9 are both electrically connected to the controller 12 .

[0023] Specifically, the spraying device 4 is a cuboid pipe arranged on the tank body, a plurality of holes are arranged on the bottom surface o...

Embodiment 2

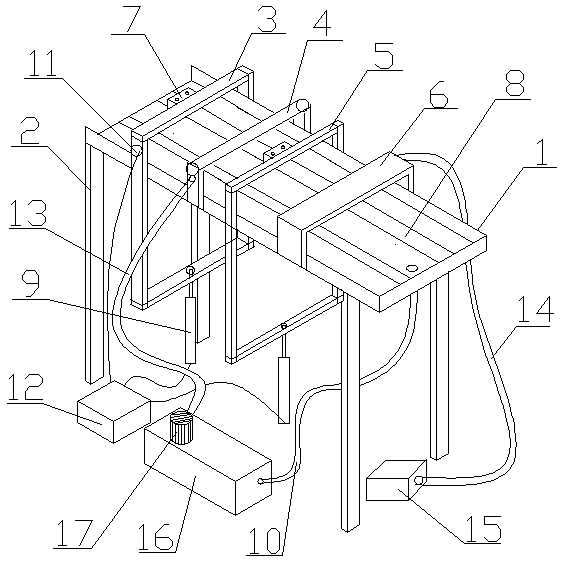

[0026] Such as figure 2 As shown, a shock absorber piston rod automatic cleaning device, the tank body 1 is arranged obliquely on a plurality of support columns 2, the first buffer frame 3, the spray device 4, the second Buffer block frame 5 and blowing device 6, on described first buffer block frame 3 and described second buffer block frame 5 all be provided with stopper 7, in described groove body 1, two horizontal bars 8 are suspended in the air, and described groove An electric push rod 9 supporting the buffer frame is arranged under the body 1, a drain hole is arranged on the bottom surface of the tank body 1, and a drain pipe 10 is connected to the drain hole, and a moving sensor 11 is arranged on the first buffer frame 3 , the motion sensor 11 and the electric push rod 9 are both electrically connected to the controller 12 .

[0027] Specifically, the spraying device 4 is a cuboid pipe arranged on the tank body, a plurality of holes are arranged on the bottom surface ...

Embodiment 3

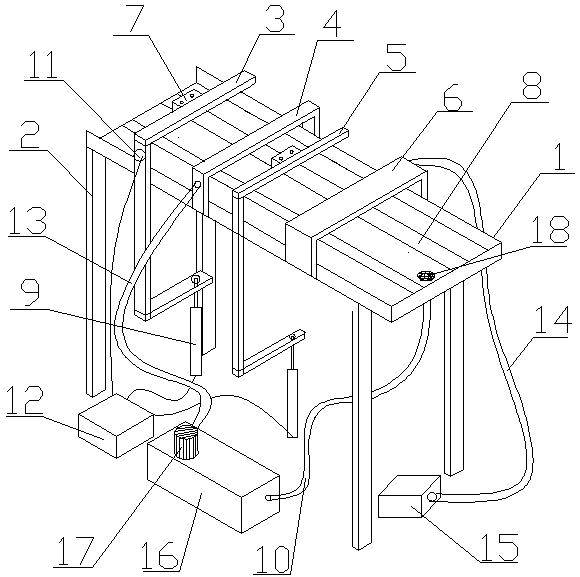

[0030] Such as image 3 As shown, a shock absorber piston rod automatic cleaning device, the tank body 1 is arranged obliquely on a plurality of support columns 2, the first buffer frame 3, the spray device 4, the second Buffer block frame 5 and blowing device 6, on described first buffer block frame 3 and described second buffer block frame 5 all be provided with stopper 7, in described groove body 1, two horizontal bars 8 are suspended in the air, and described groove An electric push rod 9 supporting the buffer frame is arranged under the body 1, a drain hole is arranged on the bottom surface of the tank body 1, and a drain pipe 10 is connected to the drain hole, and a moving sensor 11 is arranged on the first buffer frame 3 , the motion sensor 11 and the electric push rod 9 are both electrically connected to the controller 12 .

[0031]Specifically, the spraying device 4 is a cuboid pipe arranged on the tank body, a plurality of holes are arranged on the bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com