Method for controlling investment casting to solidify

A technology for investment casting and casting, applied in the field of controlling the solidification of investment casting castings, can solve the problems of shrinkage, shrinkage, poor heat dissipation, etc., to avoid shrinkage, improve yield and yield, and speed up solidification and cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

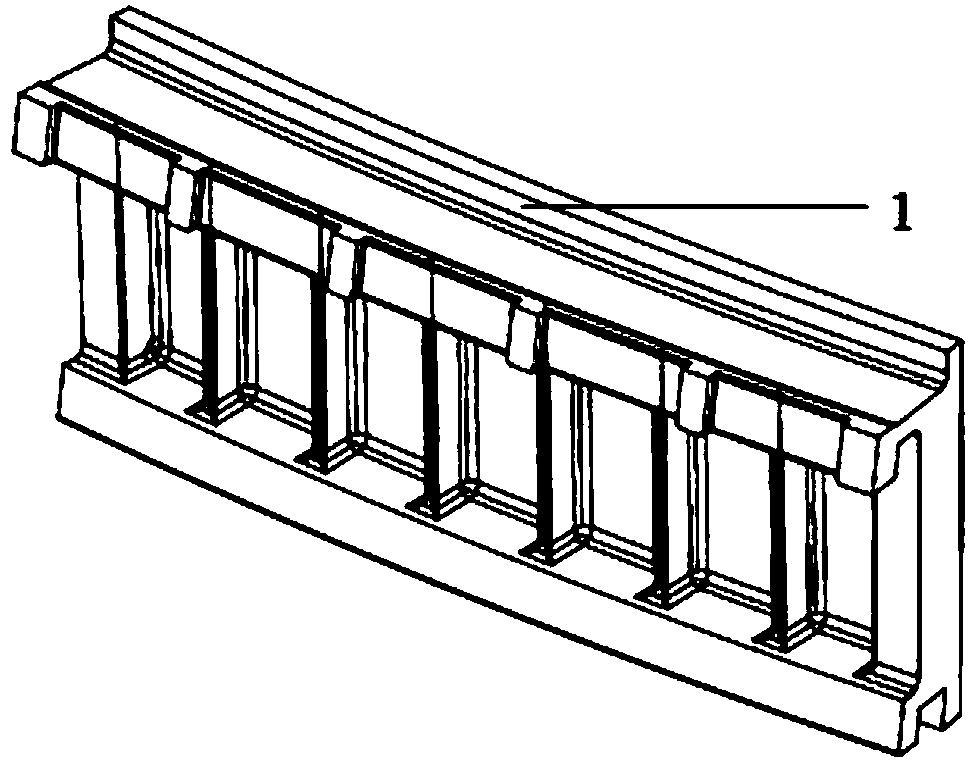

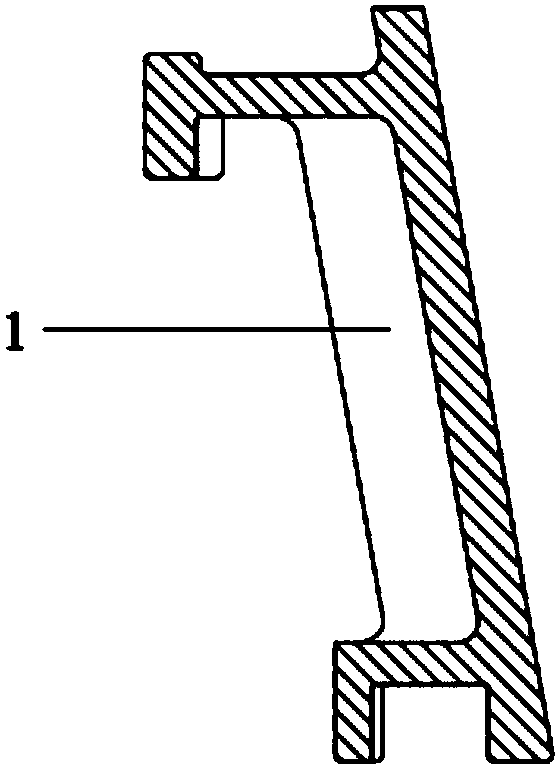

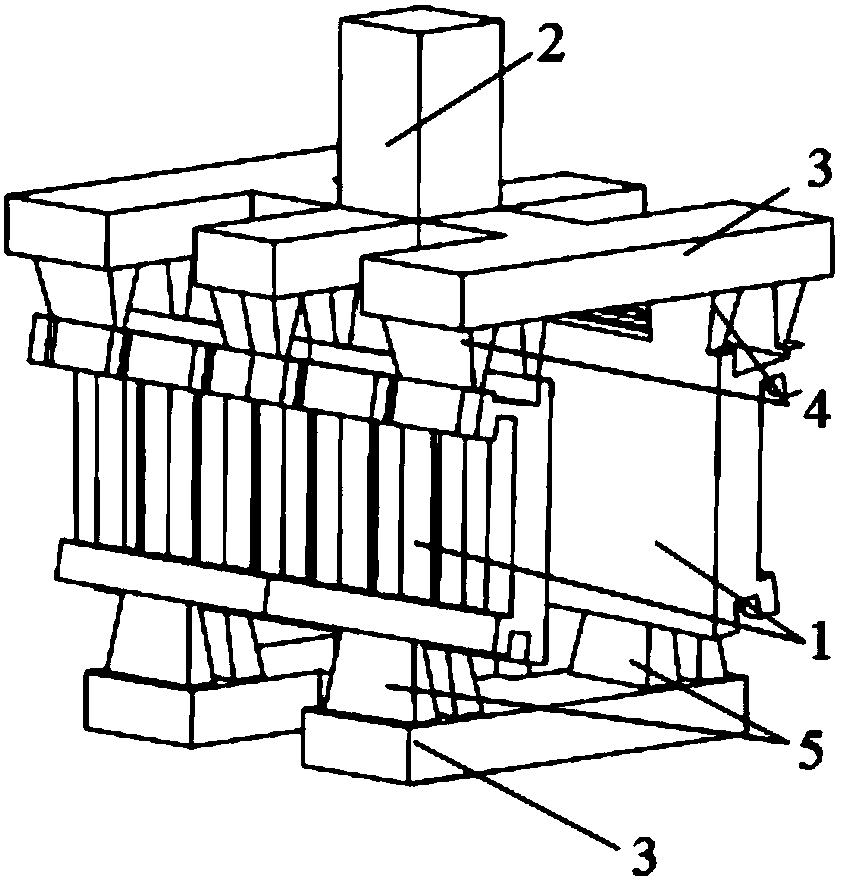

[0033] The casting 1 structure of a type II retaining ring is a ring structure (such as figure 1 shown), the cross-sectional shape is "I"-shaped structure (such as figure 2 As shown), during the process design, there is always a hot spot in the lower triangular area, which is difficult to completely eliminate, and eventually leads to shrinkage cavity and shrinkage porosity defects in this part. According to this invention, using such as image 3 and Figure 4 According to the process scheme shown, according to the shape and process requirements of the casting 1 of the type II retaining ring, set the sprue 2 and the runner 3, as well as the riser 4 and the ingate 5 and determine their positions. First, use the ProCAST software The simulation analysis shows that the immersion process parameters are immersion depth of 30 mm and immersion time of 10 seconds; after the wax model is made and the wax model is assembled, the wax model is coated with paint according to the process. ...

Embodiment 2

[0035] A shell casting 1 such as Figure 5 As shown, the weight of the casting is up to 13Kg, and the top-riser horizontal process is adopted in the process design. During actual pouring, shrinkage cavities or shrinkage defects often appear at the bottom of the flanges on both sides. After applying this invention, it is used to control investment casting castings For the method of solidification, after the simulation of the casting process simulation software, the water immersion process parameters are obtained as the immersion depth of 50mm, and the immersion time is not less than 35 seconds. In actual production, according to this process, when the seventh layer is completed in the coating shell, use The mold shell is reinforced with iron wires, and the distance between the iron wires is about 50mm, and it is reinforced in a mesh shape, and then the shell-making process of the next three layers of paint is completed; then, after dewaxing and roasting, stainless steel water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com