Casting composite molding method and application of casting

A compound molding and casting molding technology, which is applied in the direction of casting molding equipment, casting molds, and casting mold components, can solve the problem of accelerating the solidification and cooling rate of the main body of thick and large castings, slowing down the solidification and cooling rate of the riser of castings, and the inability to achieve refinement at the same time Problems such as the metallurgical quality of the core structure of the main body of the casting, to achieve the effect of accelerating the solidification cooling rate, slowing down the solidification cooling rate, and realizing the refinement of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1 Composite molding and casting of a titanium-aluminum supercharger turbine with an outer diameter of 100 mm

[0075] The turbine is formed by vertical centrifugal casting method, the outer diameter of hub 1 is 100mm, and the outer diameter of feeding riser 2 is 80mm; the casting process parameters include:

[0076] The pouring temperature is 1600-1650°C, the mold preheating temperature is 400-600°C, and the centrifugal speed is 600-1000rpm.

[0077] Composite modeling of cast turbines:

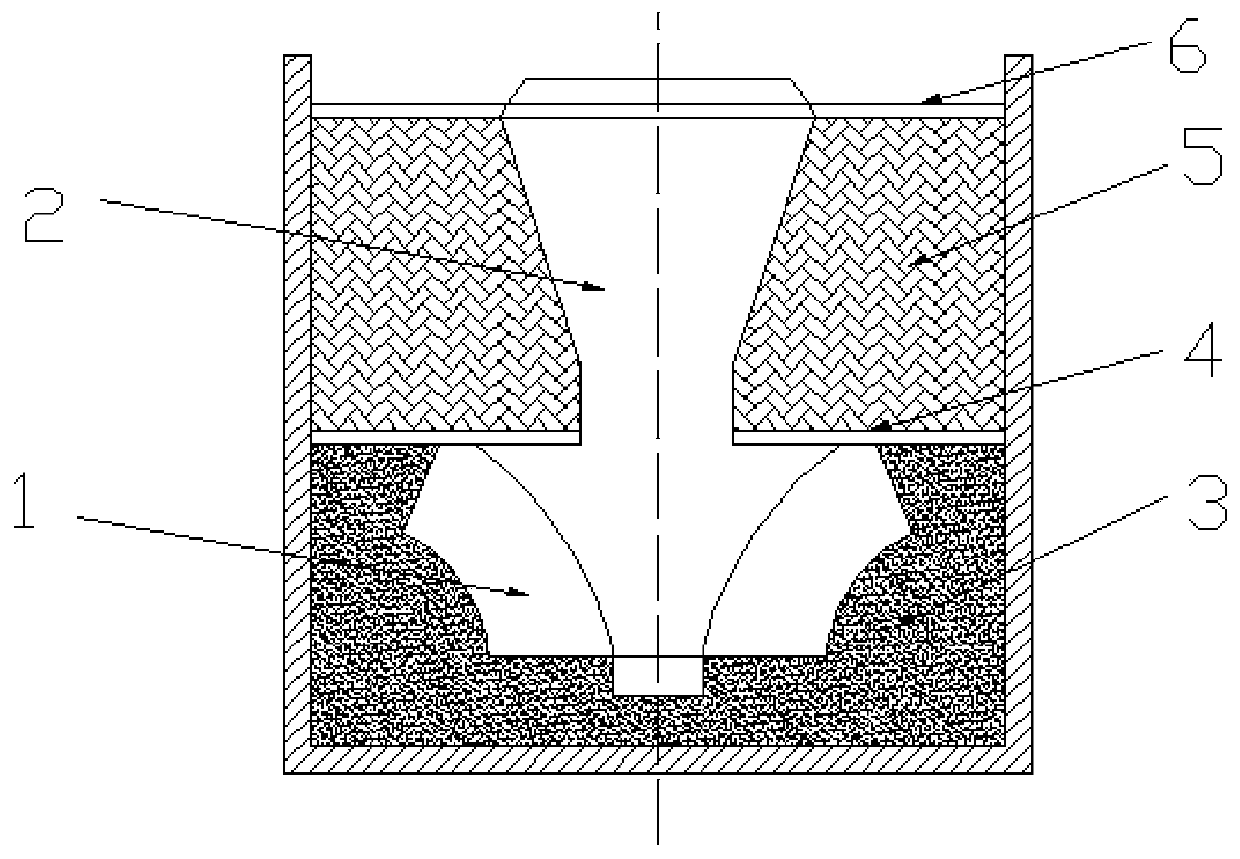

[0078] Such as figure 1 As shown in , the ceramic shell (1+2) of the turbine is placed in the sand box, the turbine hub 1 is on the bottom, the feeding riser 2 is on the top, and the hub surface is connected to the feeding riser;

[0079] Use 1.0~5.0mm granular and the particle size distribution is D 70 =3mm, thermal conductivity 407W·m -1 ·K -1 , heat storage coefficient 325W m -2 ·K -1 Copper molding sand 3 shapes the part below the hub surface of the turbine, and the ...

Embodiment 2

[0083] Example 2 Composite molding and casting of titanium-aluminum supercharger turbine with hub outer diameter of 160mm

[0084] The turbine is molded by vertical centrifugal casting method, the outer diameter of hub 1 is 160mm, and the outer diameter of feeding riser 2 is 100mm; the casting process parameters include:

[0085] The pouring temperature is 1600-1650°C, the mold preheating temperature is 200-400°C, and the centrifugal speed is 300-600rpm.

[0086] Composite modeling of cast turbines:

[0087] Such as figure 1 As shown in , the ceramic shell (1+2) of the turbine is placed in the sand box, the turbine hub 1 is on the bottom, the feeding riser 2 is on the top, and the hub surface is connected to the feeding riser;

[0088] Use 1.0~5.0mm granular and the particle size distribution is D 70 =2mm, thermal conductivity 200W·m -1 ·K -1 , heat storage coefficient 191W m -2 ·K -1 Aluminum molding sand 3 shapes the part below the hub surface of the turbine, and the ...

experiment example

[0097]Cut out the metallographic sample of the turbine hub core obtained by casting in Example 1, Example 2 and Comparative Examples 1 and 2, and after grinding and polishing using the standard metallographic sample preparation method, observe microscopic defects under an optical microscope at 100 times. The backscattered scanning electron microscope is used to count the interlamellar spacing according to the quantitative metallographic method of GB / T5749. Among them, the optical microscope adopts LEICA MEF4A image analyzer, and the backscattered scanning electron microscope adopts JEOL JSM7800 scanning electron microscope of JEOL Company.

[0098] Embodiment 1, 2 and comparative example 1, 2 turbine core quality comparison results are listed in table 1:

[0099] Table 1 Quality comparison results of turbine core

[0100]

[0101] From the results in Table 1, it can be found that:

[0102] Compared with Comparative Example 1, after adopting the composite molding method in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com