Drilling device for bulletproof helmets

A technology for bulletproof helmets and drilling devices, which is applied in the directions of boring/drilling, drilling/drilling equipment, metal processing, etc., and can solve the problems of affecting the suspension and installation of helmets, time-consuming and laborious, and large errors in drilling position accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

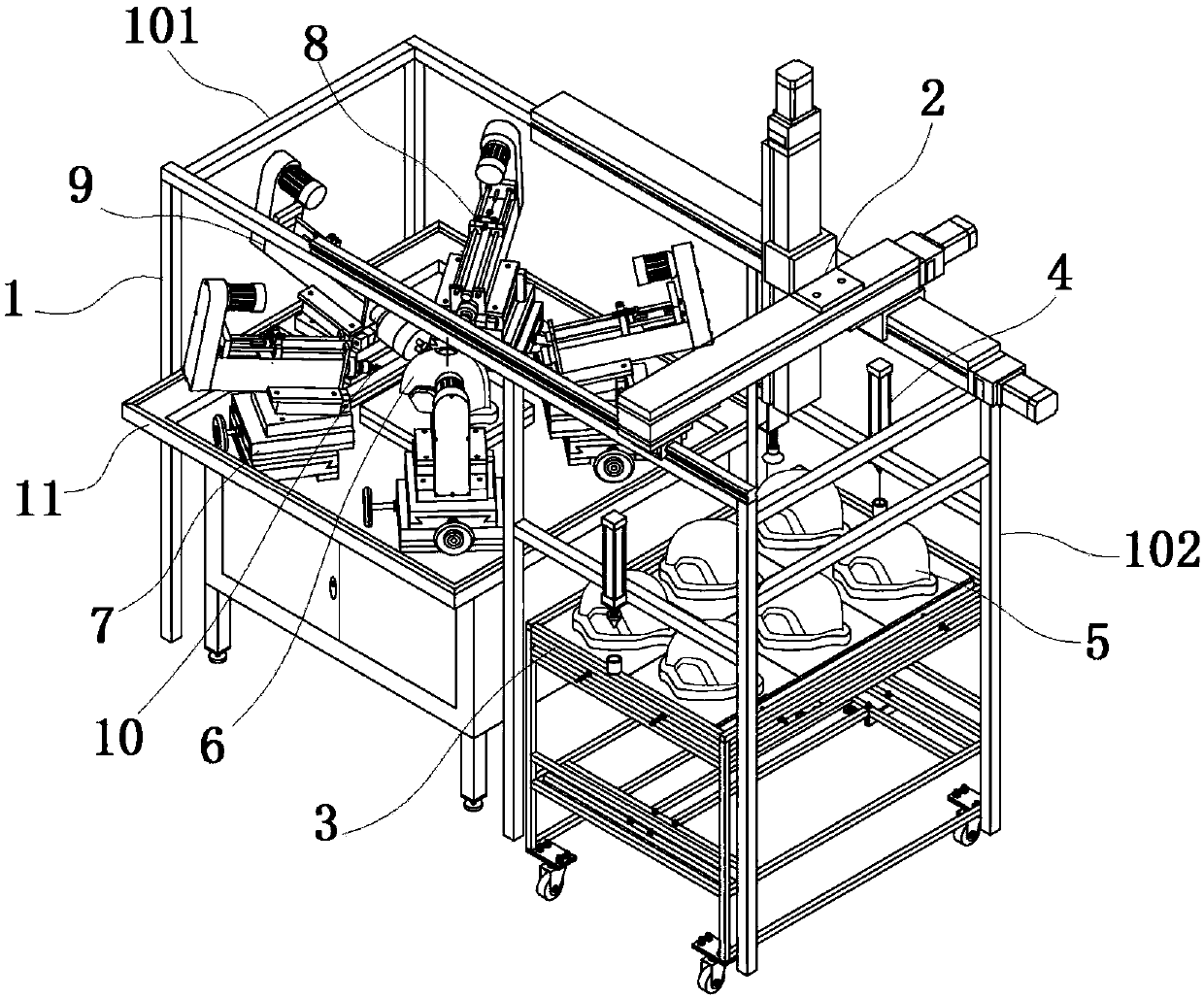

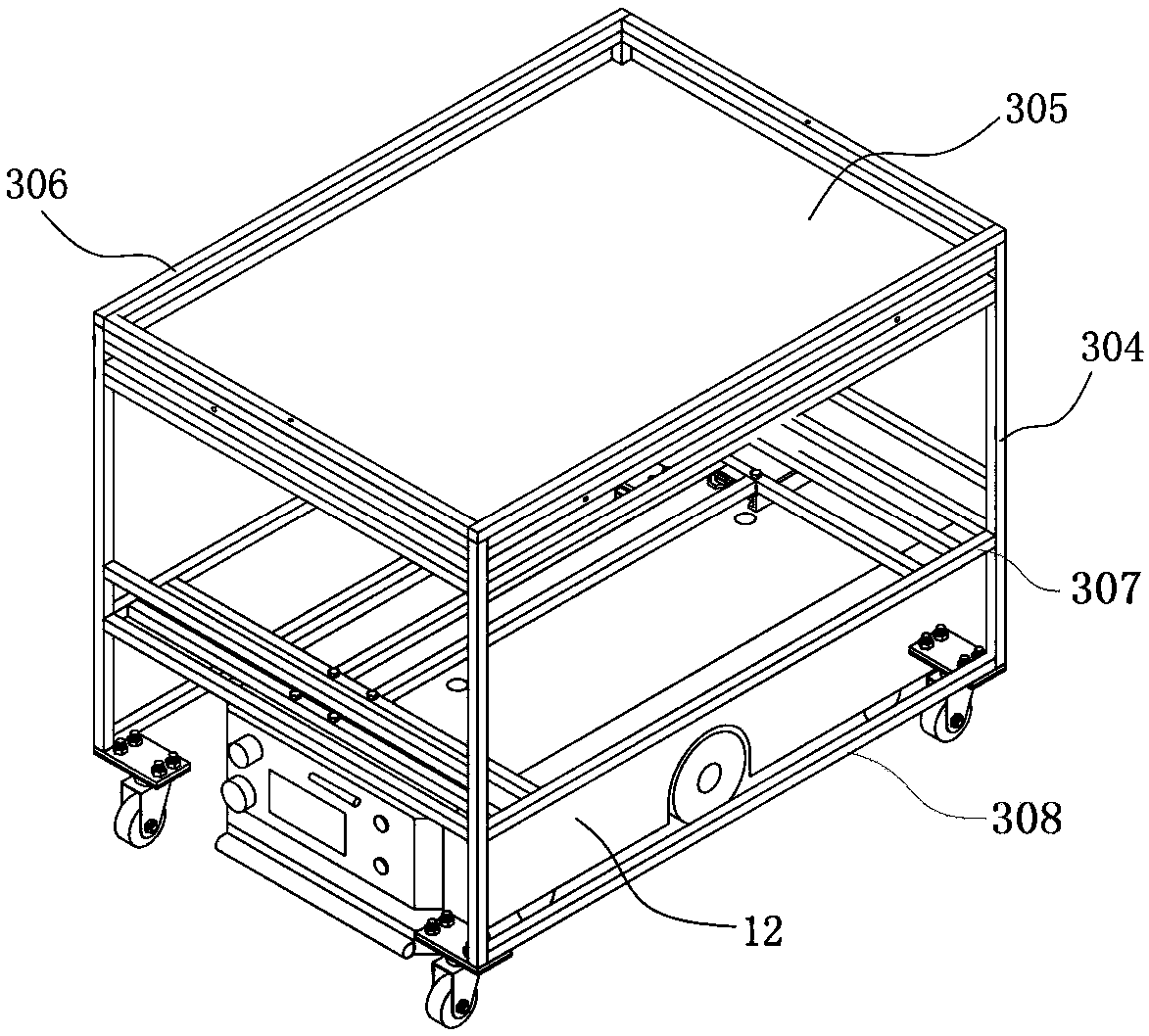

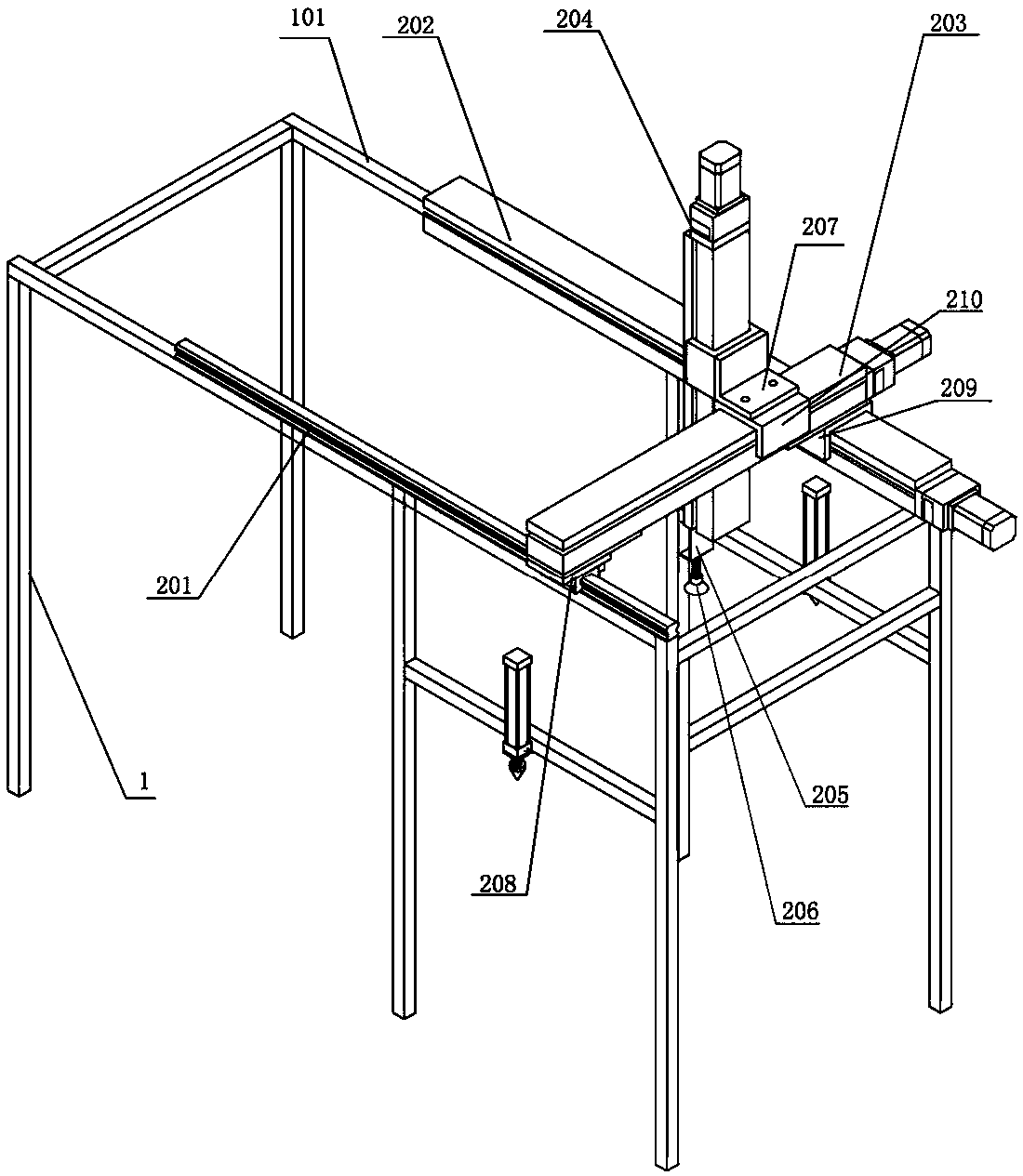

[0041] as attached figure 1 , 2 , 20, the present invention includes a frame, a bulletproof helmet conveying vehicle 3, a bulletproof helmet grabbing and returning device 2, a conveying vehicle positioning device 4, a conveying vehicle bulletproof helmet positioning device 5, a bulletproof helmet drilling and positioning mold and an ejector Device 6, multifunctional adjustment base 7, single-bit gas-electric integrated drilling device 8, double-bit gas-electric integrated drilling device 9, and drill bit 10; On the end of the drill bit gas-electric integrated drilling device 9; the bulletproof helmet conveying vehicle 3 includes a vehicle frame body 304, a bulletproof helmet mold mounting platform 305 and a fence 306, and universal rubber wheels 309 are installed on the four corners of the lower frame 308 The drill bit 10 includes a drill shank 104, a cylindrical connecting body 105 fixedly installed on the end of the drill shank 104 and a drill bit body 106 fixed on the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com