Ship bottom model modeling method and molding ship bracket

A modeling method and ship bottom technology, applied in ship construction, ship parts, household components, etc., can solve the problems of poor machining performance, long production cycle, complex process, etc., and achieve low production cost, high safety, production and The effect of simple construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

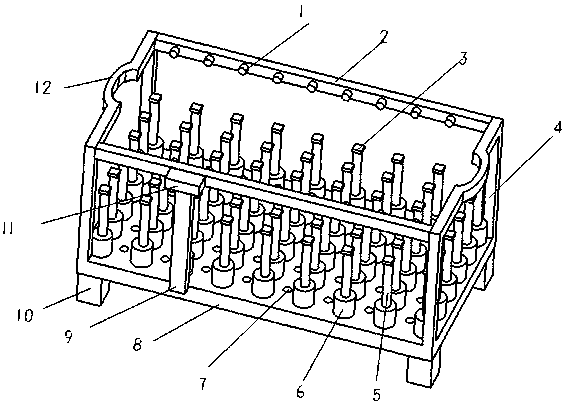

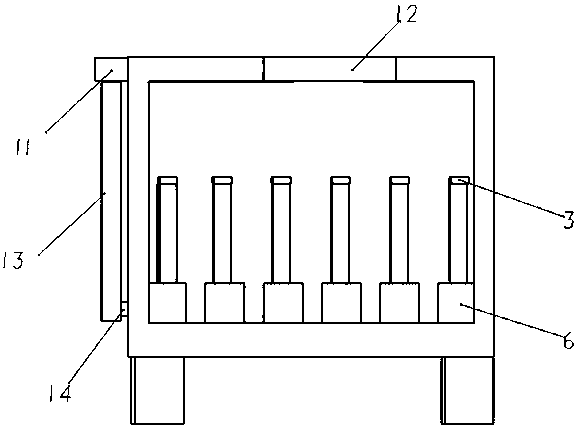

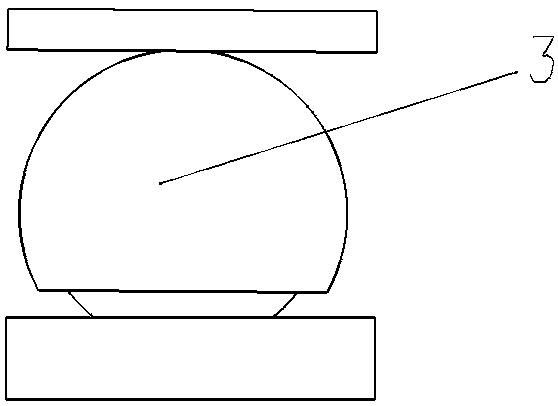

[0032] Such as figure 1Shown, a kind of modeling method of ship bottom model, it is characterized in that: step 1, place the large-scale plastic cloth with good airtightness on the molded ship bracket, the four weeks of described plastic cloth are fixed with stopper and sealant Installed on the frame of the molded ship bracket; step 2, the plastic cloth is covered with at least two layers of plastic film, and then at least two layers of kapok, shredded paper and flexible chain are spread on the plastic film The material forms miscellaneous material layer, and spreads plastic film on the top of miscellaneous material layer; Step 3, puts into the ship bottom mold to be molded, adjusts the height of the hydraulic device on the molded ship bracket according to the bottom shape of the ship bottom mould, At the same time, cooperate with the steering limit device to establish a prototype of the shape of the bottom of the ship, adjust the molded ship bracket to the contour and line of...

Embodiment 2

[0040] The structure and principle of the second embodiment are basically the same as the first embodiment, the difference is that the sequence of operation is changed, the epoxy resin mixture is first poured into the bracket of the molded ship, and then the height of the hydraulic device of the bracket of the molded ship is adjusted. Form the desired shape for the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com