Carbon fiber plate and production method thereof

A carbon fiber board and production method technology, applied in the field of carbon fiber materials, can solve the problems of insufficient strength and shock resistance, and achieve the effects of improving strength, increasing toughness, and increasing shock resistance and buffering capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

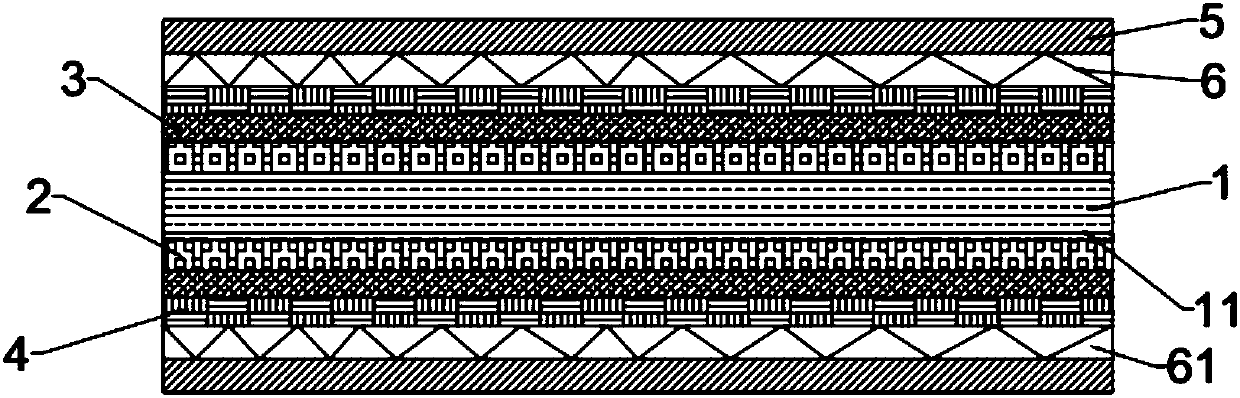

[0020] Such as figure 1 As shown, a carbon fiber plate includes a base plate, the upper and lower surfaces of the base plate are covered with a glass fiber layer, the glass fiber layer is provided with a carbon fiber cloth, the surface of the carbon fiber cloth is provided with a reinforcing plate, and several head and tail plates are arranged between the reinforcing plate and the carbon fiber cloth. The supporting carbon fiber plates are connected and arranged in a zigzag shape, and a filling layer is arranged between the carbon fiber plates.

[0021] Such as figure 1 As shown, a plastic film is arranged between the glass fiber layer and the carbon fiber cloth.

[0022] Such as figure 1 As shown, the substrate includes 30-100 layers of carbon fiber mesh.

[0023] Such as figure 1 As shown, the filled layer is a cured layer of vinyl ester resin.

[0024] Such as figure 1 As shown, the supporting fiberboard and the carbon fiber cloth are integrally formed by weaving.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com