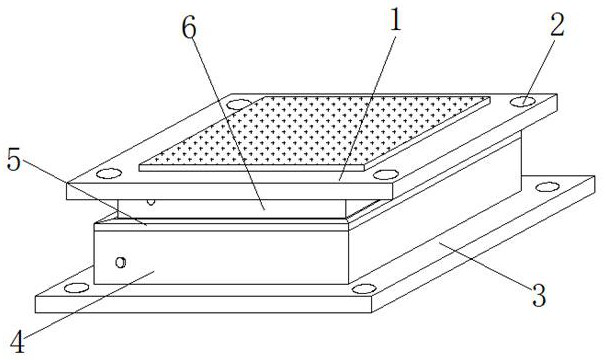

Grid type box soft steel damper applied to bridges and structural engineering

A mild steel damper and structural engineering technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as limited seismic capacity of bridges, damage of bridge support columns, and impact on safe use of bridges, so as to avoid damage and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

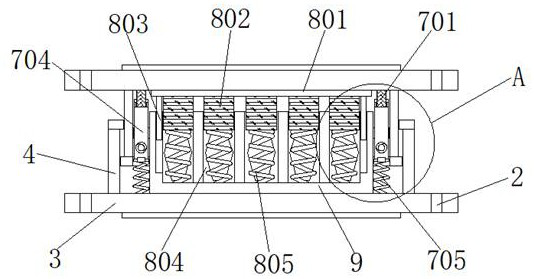

[0030] Example 1, such as figure 1 , 3 , 4, 5 and 7, when the top of the upper connecting plate 1 is subjected to a larger force, the upper connecting plate 1 drops a little distance, the slider 803 slides downward inside the chute 806, and the movable rod 802 moves in the square The inside of the groove 804 slides down a little. At this time, the shock absorbing spring 805 is shortened by force and stores a certain amount of elastic potential energy to buffer the force on the upper connecting plate 1. If the force on the upper connecting plate 1 is relatively large, the upper connecting plate 1 When the bottom of the plate 1 is in contact with the top of the outer limit ring 5, a part of the force received by the upper connecting plate 1 will be transmitted to the body of the installation warehouse 9. Since the inside of the square groove 804 is uniformly provided with a plurality of groups of through holes 808, and through A "Z" shaped ductile steel rod 807 is arranged insi...

Embodiment 2

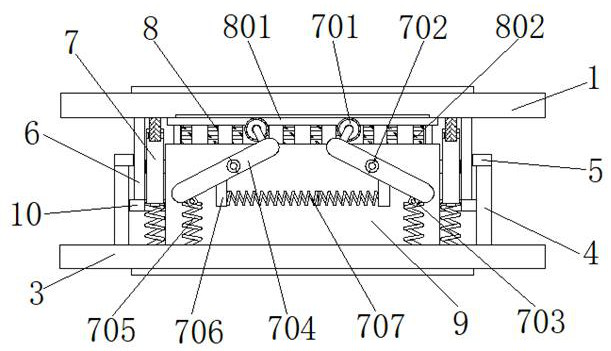

[0031] Example 2, such as Figure 1-3 As shown, when the force on the upper connecting plate 1 is constantly changing, the distance between the upper connecting plate 1 and the lower connecting plate 3 is continuously shortened or elongated slightly, so that the roller 701 is constantly rolling back and forth on the bottom of the upper connecting plate 1 , the connecting rod 704 is forced to continuously rotate forward and backward at a certain angle with the rotating shaft 702 as the axis, and when the two sets of rollers 701 roll close to each other, the buffer spring A 705 is stretched to store elastic potential energy, and the buffer spring B 707 is also connected by the two groups The rod 704 is elongated to store elastic potential energy, and when the distance between the upper connecting plate 1 and the lower connecting plate 3 increases slightly, the two sets of rollers 701 roll away from each other, and at this time, the buffer spring A 705 and the buffer spring B 707 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com