An automatic laminating machine

A technology of a laminating machine and a transmission mechanism, which is applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of high labor intensity, low economic benefits, and influence on the quality of lamination, and achieve cost savings, structural Simple, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

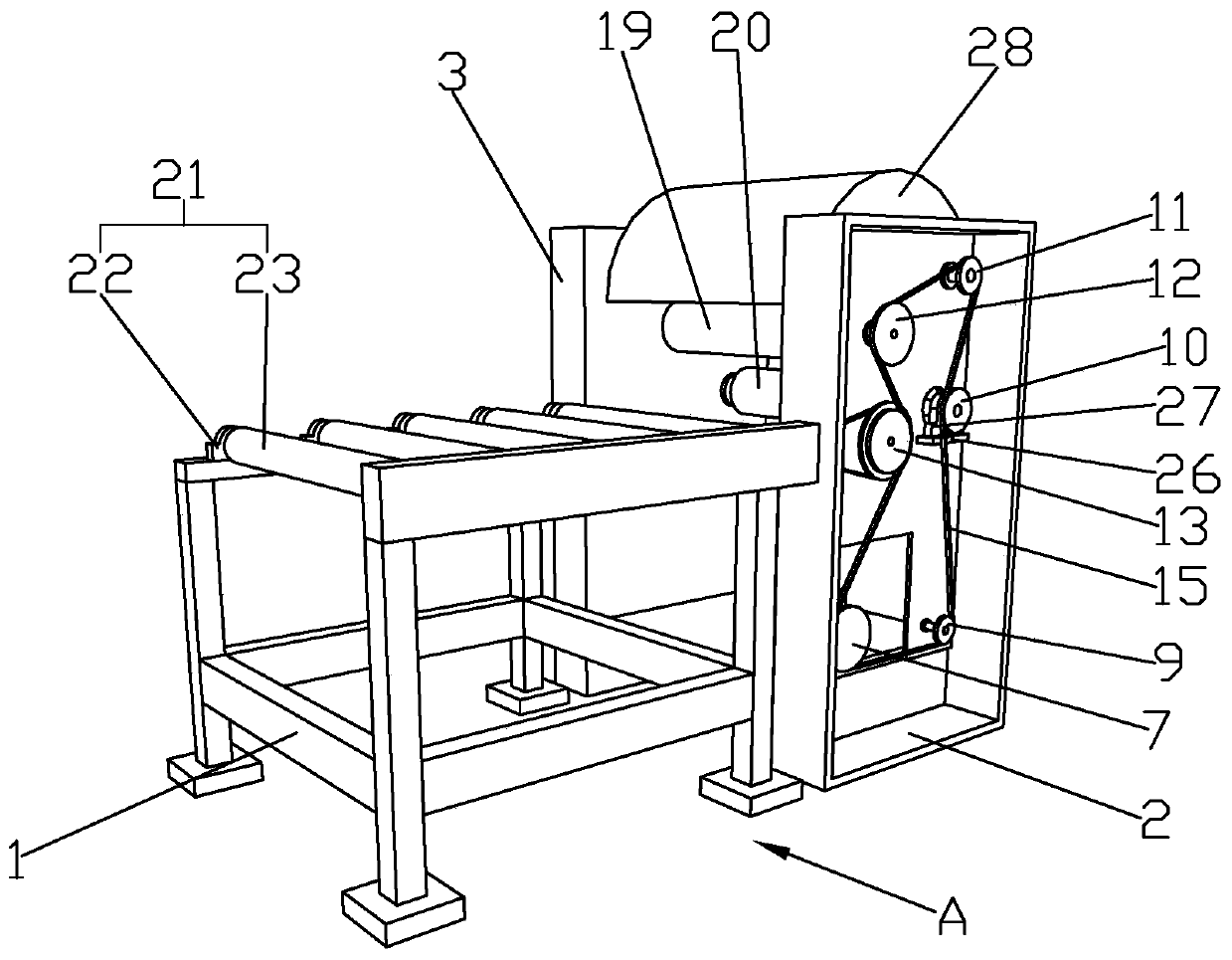

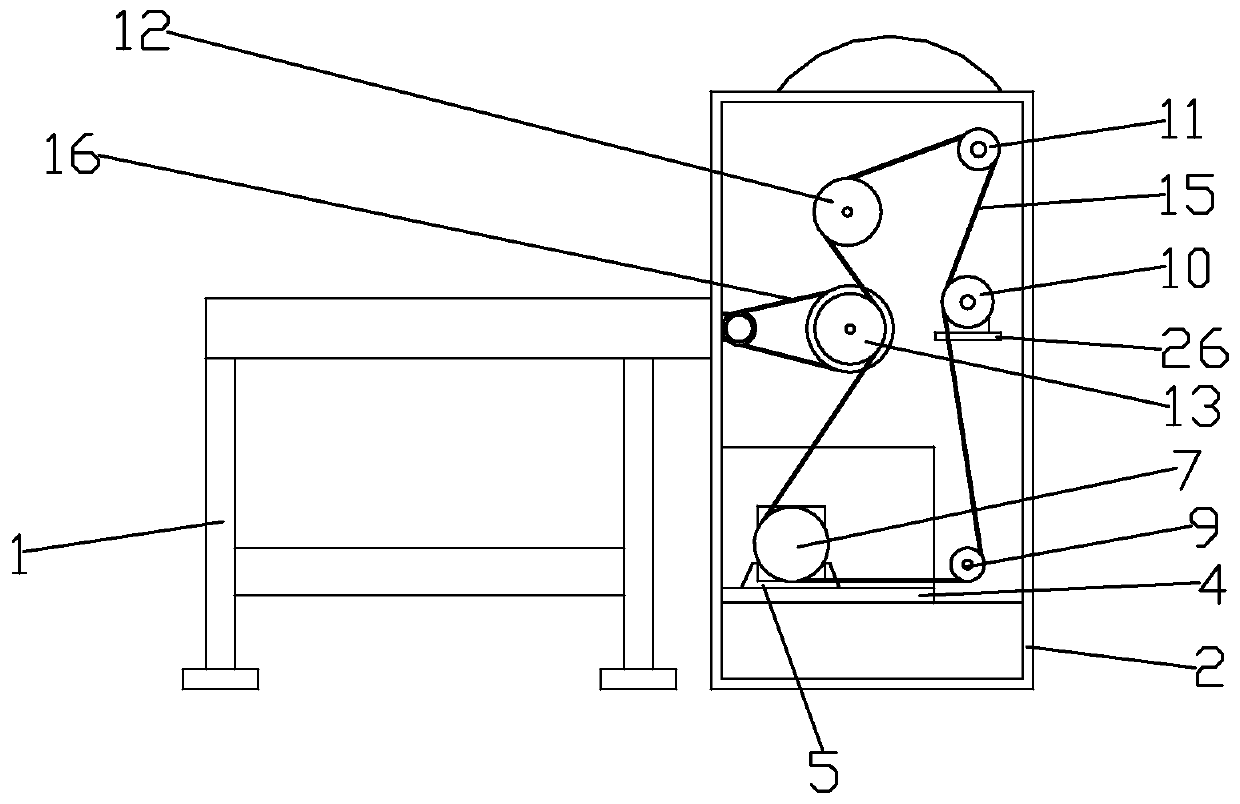

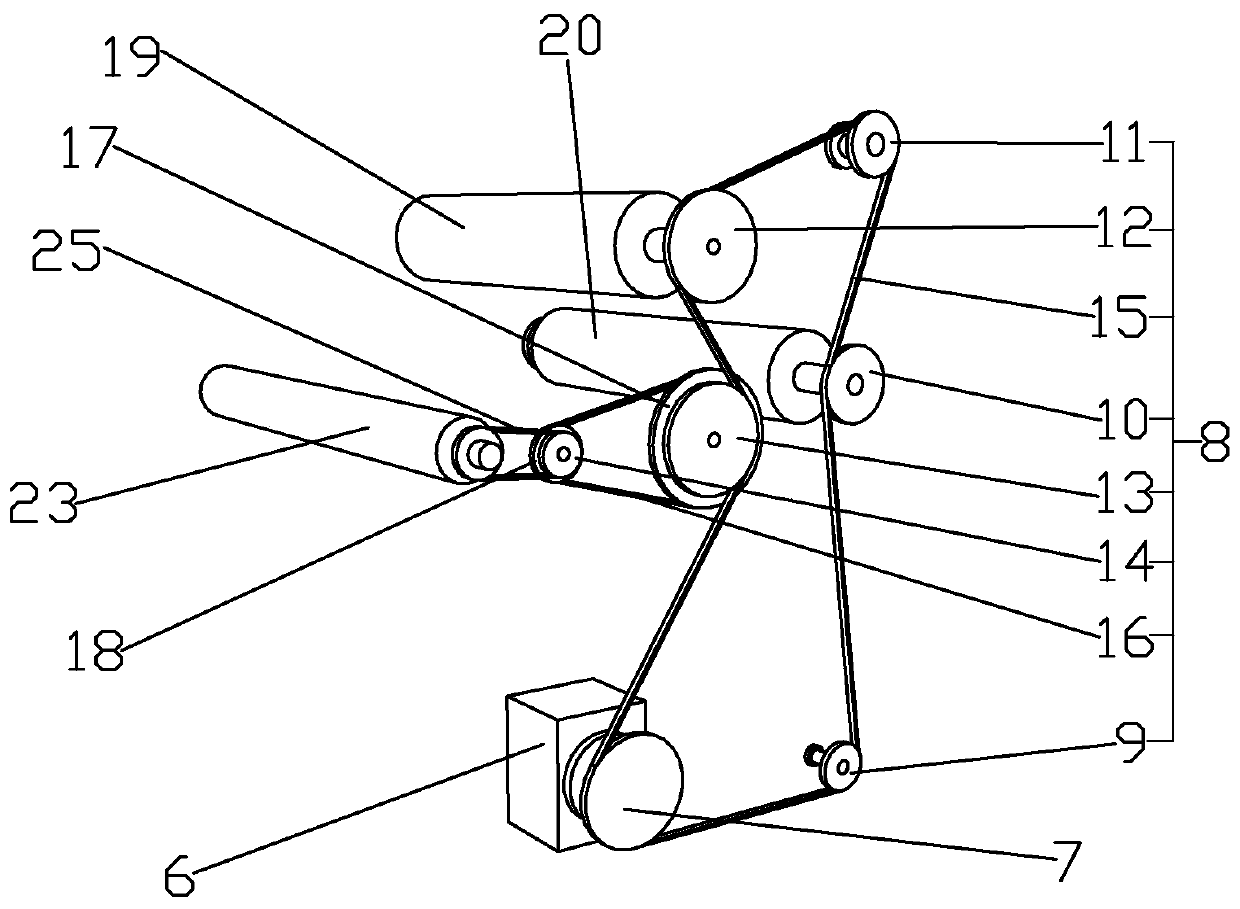

[0018] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

[0019] like Figure 1-5 The described automatic laminating machine comprises a base frame 1, a first support platform 2 and a second support platform 3, and the first support platform 2 and the second support platform 3 are respectively arranged on the base frame 1 On one side, a balance plate 4 is provided between the first support platform 2 and the second support platform 3, a support base 5 is provided on the balance plate 4, a motor 6 is provided on the support base 5, and a motor 6 Vibration will be generated during operation, and the setting of support base 5 can disperse these vibration effects and improve the stability of motor 6 during operation. The motor 6 is connected with a driving wheel 7, and the first supporting platform 2 is provided with a transmission mechanism 8, and the transmission mechanism 8 includes a first tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com