Flowing-assisting material bin with built-in inclination-angle-adjustable baffle mechanisms

A baffle mechanism and adjustable technology, applied in the directions of containers, packaging, transportation and packaging, can solve the problems of tight space layout at the outlet of the silo, unsteady flow of unloading materials, uneven material discharge, etc., so as to alleviate the flow of materials. Unsmooth, improve the reuse rate, reduce the effect of filling height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited thereto.

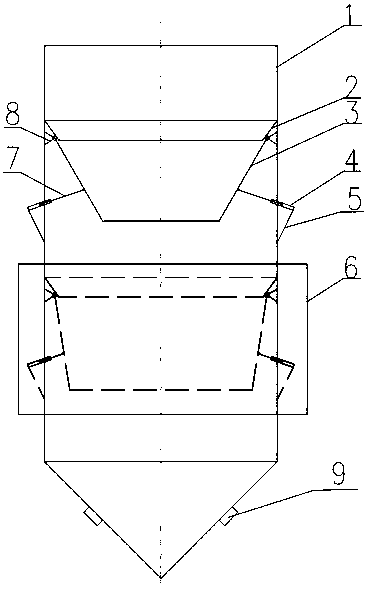

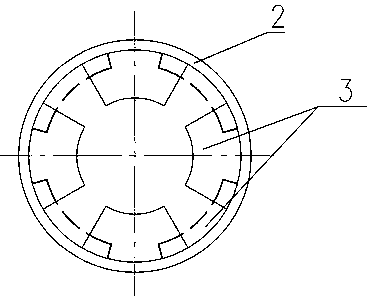

[0023] Such as Figure 1-2 As shown, a flow-aiding silo with a built-in inclination-angle-adjustable baffle mechanism of the present invention includes a flow-aiding silo body 1 formed by connecting a cylinder section and a cone section, and the cylinder of the flow-aiding silo body 1 There are at least two layers of inclination-adjustable baffle mechanism 6 in the section, and the inclination angle of the inclination-angle-adjustable baffle mechanism 6 gradually decreases from top to bottom of the cylinder section, and the inclination-angle adjustable baffle mechanism 6 includes at least 3 pieces Adjustable baffles 3 arranged at even intervals, the upper part of the adjustable baffle 3 is movably set on the inner wall of the cylinder section through the connecting piece 8, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com