Glaze capable of releasing negative oxygen ions, tile and preparation method thereof

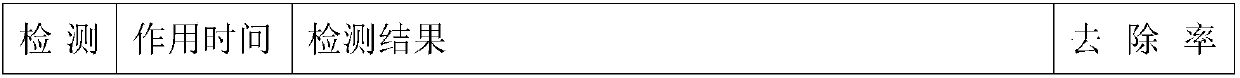

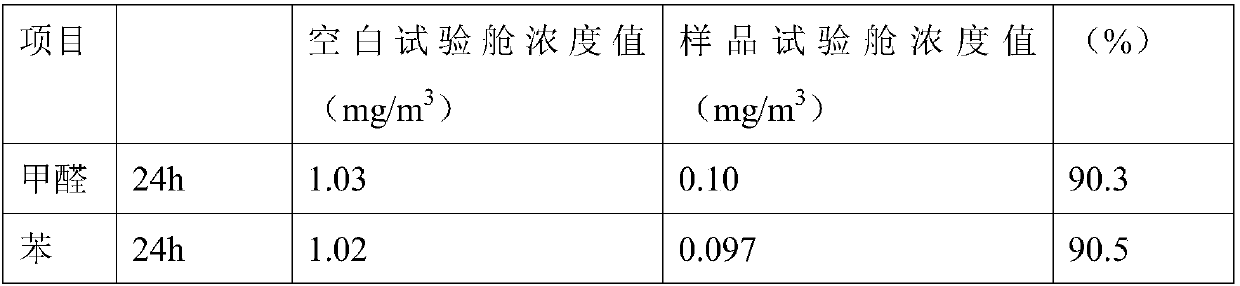

A technology of negative oxygen ions and glazes is applied in the field of interior decoration materials, ceramic tiles and their preparation, and glazes that can release negative oxygen ions. and other problems, to achieve the effect of eliminating toxic gases and sterilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of glaze that can release negative oxygen ions, adding high-energy powder in the glaze raw material, its addition ratio is 1.5wt% of the glaze raw material, and described high-energy powder includes the following components by oxide weight:

[0028] SiO 2 70 parts, Fe 2 o 3 0.5 parts, Al 2 o 3 5 parts, CaO 0.05 parts, MgO 1 part, K 2 O 1 part, Na 2 O 2 parts, TiO 2 0.8 parts, CeO 2 0.5 parts, ThO 2 4 parts.

Embodiment 2

[0030] A kind of glaze that can release negative oxygen ions is added high-energy powder in the glaze raw material, and its adding ratio is 2wt% of the glaze raw material, and described high-energy powder comprises the following composition by oxide weight:

[0031] SiO 2 90 parts, Fe 2 o 3 0.2 parts, Al 2 o 3 3 parts, CaO 0.03 parts, MgO 0.1 parts, K 2 O 0.1 part, TiO 2 0.4 parts, CeO 2 0.1 parts, ThO 2 3 copies.

Embodiment 3

[0033] A kind of glaze material that can release negative oxygen ions, add high-energy powder in the glaze raw material, its adding ratio is 3wt% of glaze raw material, described high-energy powder comprises the following composition by oxide weight:

[0034] SiO 2 80 parts, Al 2 o 3 5 parts, CaO 0.01 parts, TiO 2 0.8 parts, CeO 2 0.5 parts, ThO 22 servings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com