A kind of high flow reinforced flame retardant PBT material and preparation method thereof

A high-flow, PBT resin technology, applied in the field of polymer materials, can solve problems such as odor problems, floating fibers, and poor fluidity, and achieve the effects of improved fluidity, good dispersion, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

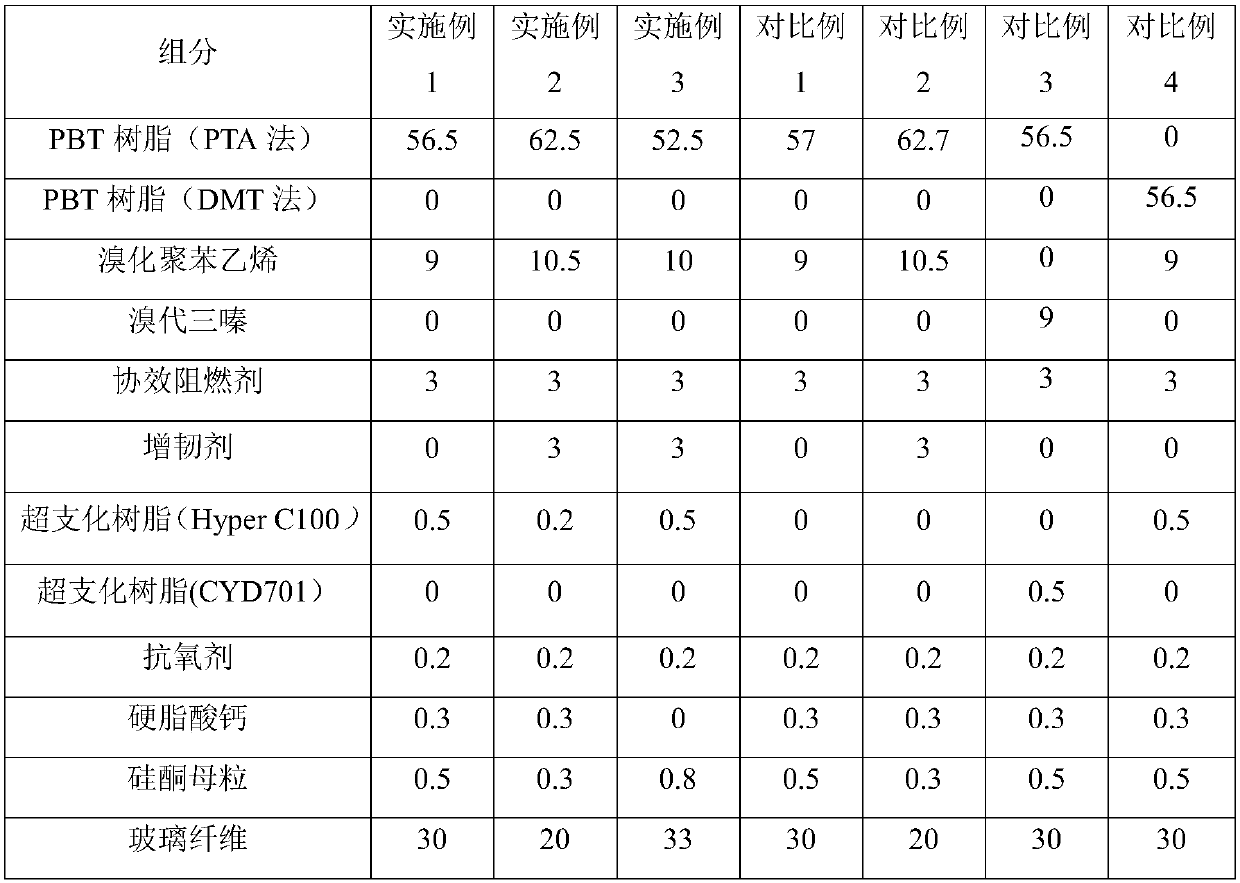

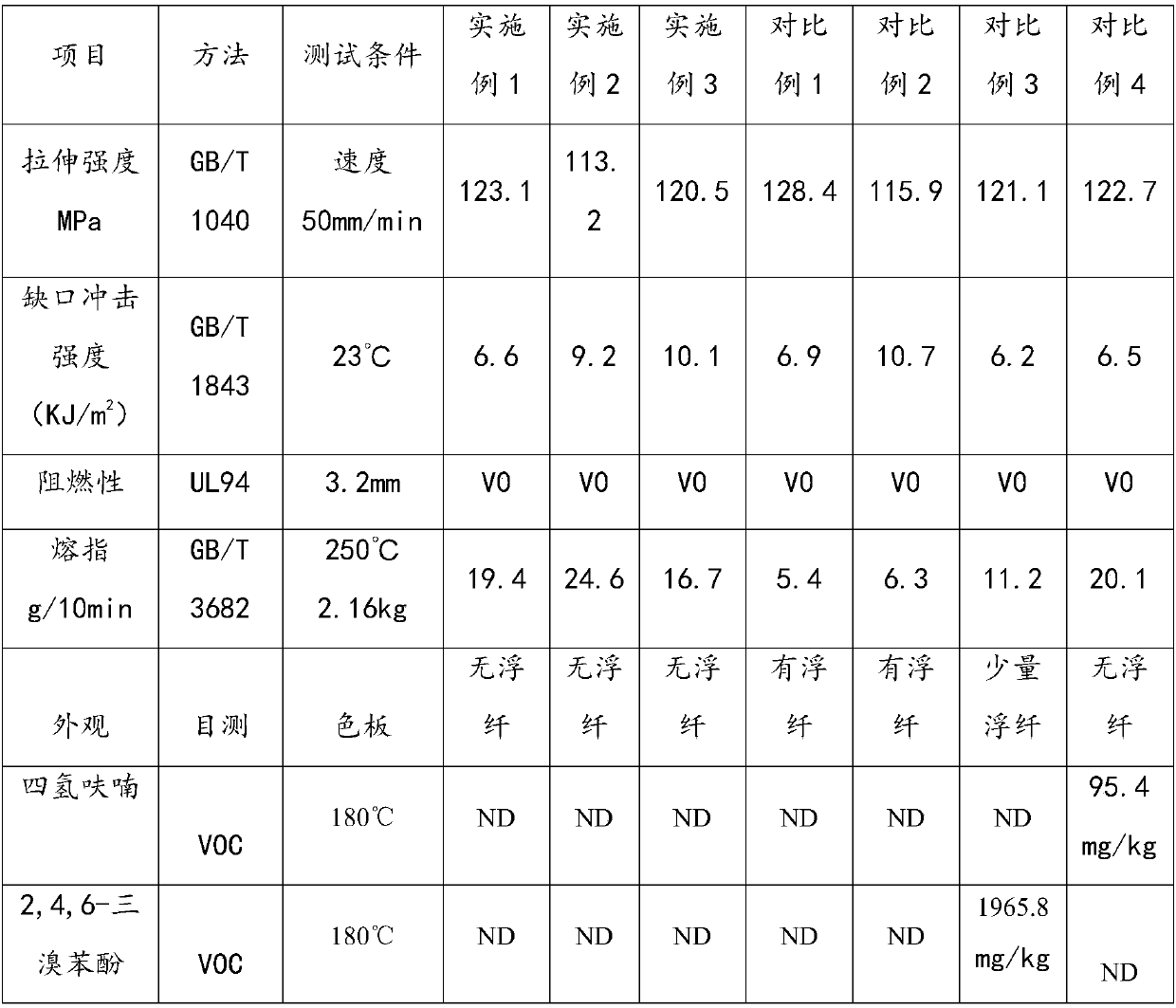

[0020] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, and the given examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0021] The methods adopted in the present invention are conventional methods without special instructions, and the raw materials used in the present invention are commercially available products without special instructions. Specifically, the PBT resin is starester@HQ-Ⅱ produced by Nantong Xingchen Company by PTA method; the main flame retardant is brominated polystyrene B-701 produced in Oseki, Japan; the synergistic flame retardant is Hunan Chenzhou ordinary grade Antimony trioxide, purity 99.8%; toughening agent is DuPont PTW, hyperbranched resin is Hyper C100 from Wuhan Hyperbranched Resin Technology Co., Ltd.; processing aids including silicone masterbatch are Dow Corning MB50-002.

[0022] The inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com