Method for preparing wave-transparent bn fiber-reinforced si-b-n ceramic matrix composites by cvd/cvi method

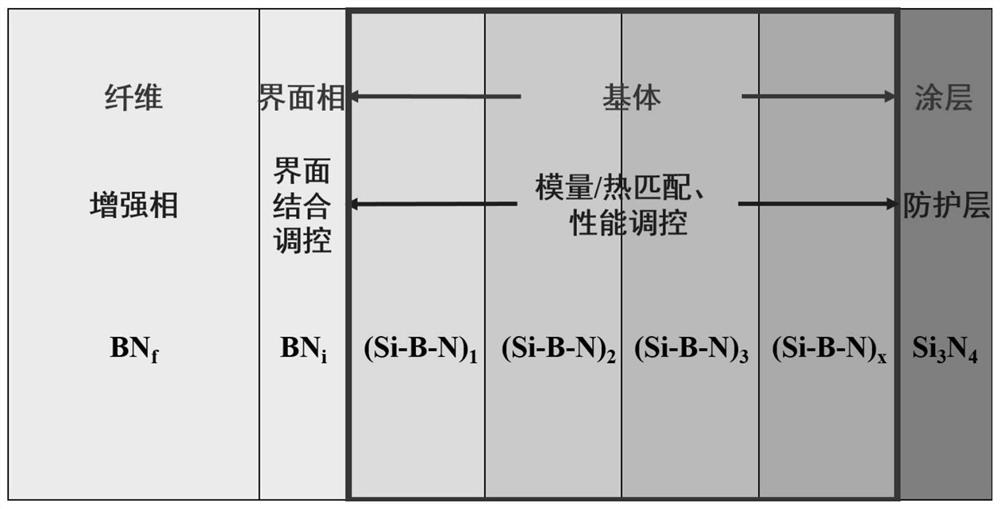

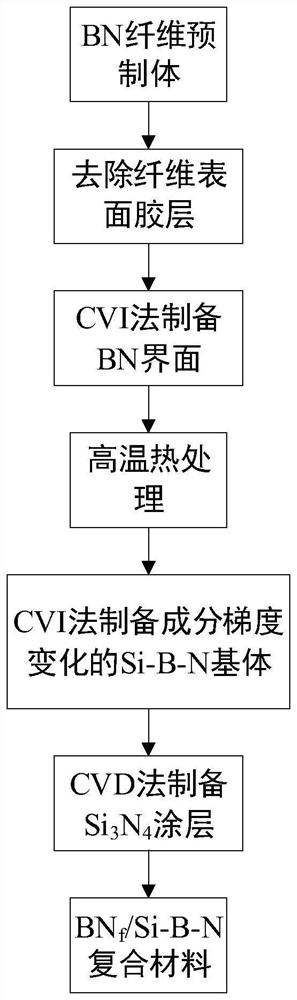

A fiber toughening and composite material technology is applied in the field of wave-transmitting BN fiber toughening Si-B-N ceramic matrix composite materials prepared by CVD/CVI method, which can solve the problem of fiber and matrix modulus and thermophysical properties mismatch, wave transmission Type CFCC lacks interface control, and the cracks and pores are not continuous and dense enough to achieve the effects of regulation and optimization, wave transmission properties and mechanical properties, and improvement of thermophysical properties mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

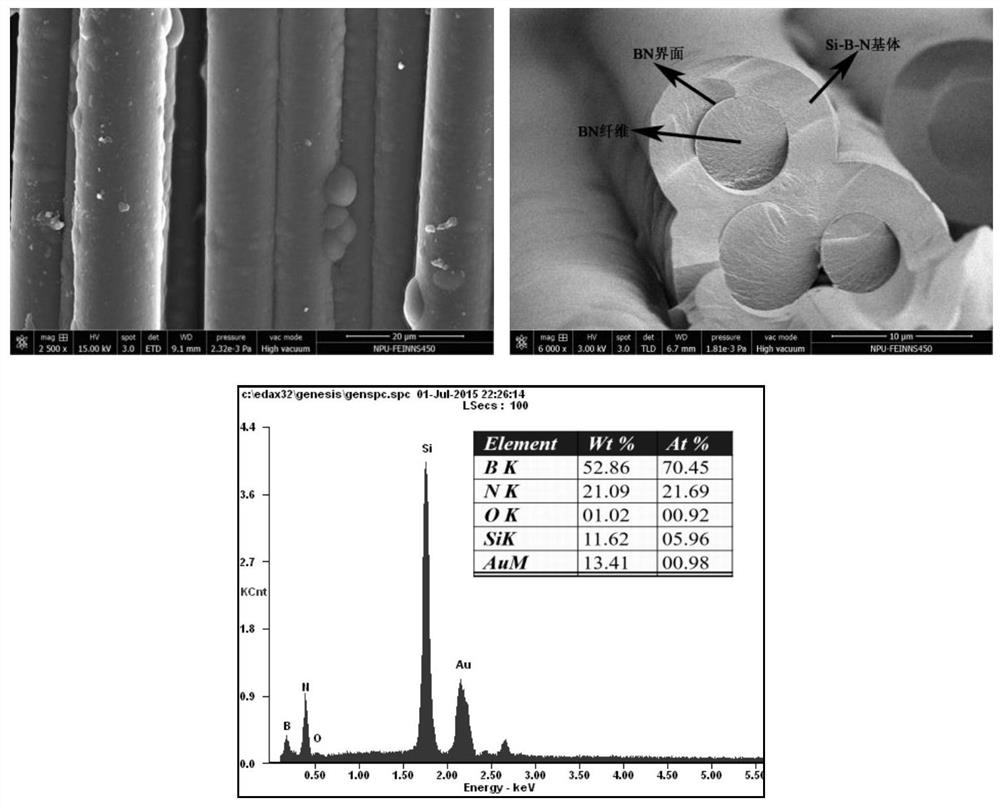

[0034] Step 1. Pretreatment of BN fiber preform. Divide 20 flat sheets into 10×10cm 2 The BN fiber cloth is soaked in xylene for 48 hours, then washed three times with xylene and three times with alcohol, and finally dried at 80°C to remove the adhesive layer.

[0035] Step 2. Preparation of BN interface. Lay the degummed BN fiber cloth in a graphite fixture to form a two-dimensional prefabricated body, and hang the prefabricated body in the isothermal zone of the deposition furnace. The deposition process parameters of the BN interface are: BCl 3 The flow rate is 100ml / min, NH 3 The flow rate is 300ml / min, H 2 The flow rate is 500ml / min, the Ar flow rate is 500ml / min, the furnace pressure is 1kPa, the deposition temperature is 650°C, the deposition time is 50h, and the thickness of the BN interface is 1500nm. Then, the BN fiber preform containing the BN interface was placed in a high temperature furnace for heat treatment, the treatment temperature was 1300°C, and the tr...

Embodiment 2

[0039] Step 1. Pretreatment of BN fiber preform. Entrust the fiber weaving unit to weave BN fiber bundles into a fiber prefabricated body with a two-dimensional and a half structure. Soak the two-dimensional semi-BN fiber prefabricated body in xylene for 48 hours, wash it three times with xylene and three times with alcohol, and finally dry it at 80°C to remove the glue layer.

[0040] Step 2. Preparation of BN interface. Hang the degummed two-dimensional semi-BN fiber preform in the isothermal zone of the deposition furnace. The deposition process parameters of the BN interface are: BCl 3 The flow rate is 100ml / min, NH 3 Flow rate is 300ml / min, Ar flow rate is 500ml / min, H 2 The flow rate is 500ml / min, the pressure in the furnace is 1kPa, the deposition temperature is 650°C, the deposition time is 40h, and the interface thickness of the prepared BN is 1000nm. Then, the BN fiber preform containing the BN interface was placed in a high temperature furnace for heat treatmen...

Embodiment 3

[0044] Step 1. Pretreatment of BN fiber preform. Entrust the fiber weaving unit to weave BN fiber bundles into a fiber prefabricated body with a three-dimensional four-way structure. Soak the three-dimensional four-way BN fiber prefabricated body in xylene for 48 hours, then wash it three times with xylene and three times with alcohol, and finally dry it at 80°C to remove the glue layer.

[0045] Step 2. Preparation of BN interface. Hang the three-dimensional four-directional BN fiber preform after degumming in the isothermal zone of the deposition furnace. The deposition process parameters of the BN interface are: BCl 3 The flow rate is 100ml / min, NH 3 Flow rate is 300ml / min, Ar flow rate is 500ml / min, H 2 The flow rate is 500ml / min, the pressure in the furnace is 1kPa, the deposition temperature is 750°C, the deposition time is 15h, and the interface thickness of the prepared BN is 800nm. Then, the BN fiber preform containing the BN interface was placed in a high temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com