Inorganic grease composition and preparation method thereof

A lubricating grease composition and the technology of the composition are applied in the field of lubricating grease to achieve the effect of low raw material cost, wide application range and excellent anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

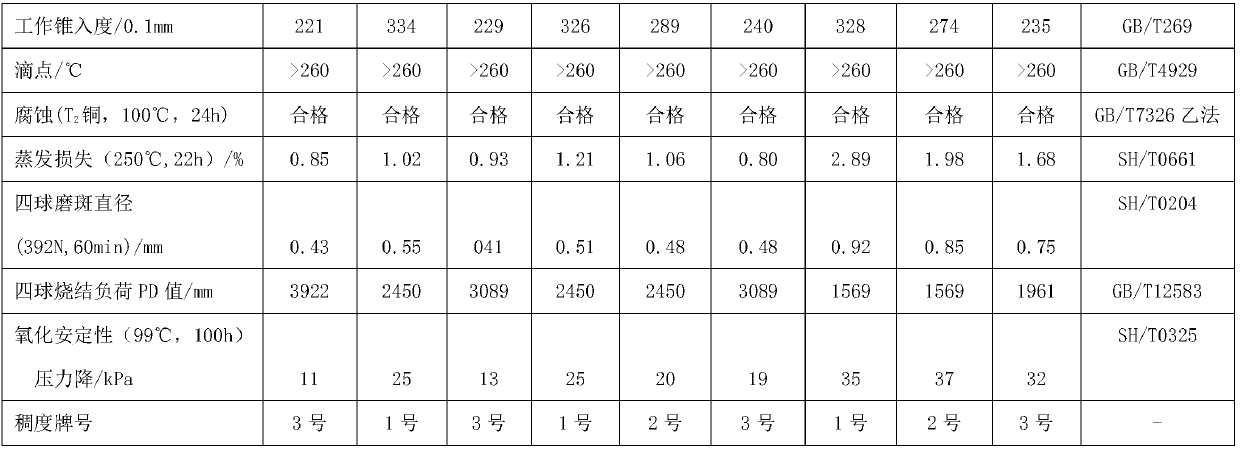

Examples

Embodiment 1

[0027] Inorganic grease composition provided by the invention, each component and mass percentage are as follows:

[0028] (1) No. 1500 synthetic cylinder oil 67.5%

[0029] (2) Modified bentonite 15.0%;

[0030] (3) active calcium carbonate 12.0%;

[0031] (4) Methanol 4.0%;

[0032] (5) phenothiazine 1.5%;

[0033] Put 380g of No. 1500 synthetic cylinder oil into the kettle, raise the temperature to 95°C, add 150g of aminated bentonite and 120g of activated calcium carbonate, and stir for 10 minutes to disperse the materials. Add methanol 40g, keep the temperature and stir for 35min. Put the remaining base oil into the kettle and stir for 120min. At a temperature of 90°C, 15 g of phenothiazine was added. Stir evenly, you can get out of the kettle. Finally, the finished product is obtained after grinding 3 times with a three-roll mill. The properties of the grease obtained are shown in Table 1.

Embodiment 2

[0035] Inorganic grease composition provided by the invention, component and mass percent are as follows:

[0036] (1) No. 1500 synthetic cylinder oil 91.1%;

[0037] (2) Modified bentonite 5.0%

[0038] (3) Active calcium carbonate 3.0%;

[0039] (4) 0.5% ethanol;

[0040] (5) phenothiazine 0.4%;

[0041] Put 460g of No. 1500 synthetic cylinder oil into the kettle, raise the temperature to 60°C, add 50g of aminated bentonite and 30g of activated calcium carbonate, and stir for 5 minutes to disperse the materials. Add 5 g of ethanol, keep the temperature and stir for 25 min. Put the remaining base oil into the kettle and stir for 60 minutes. At a temperature of 80° C., 4 g of phenothiazine was added. Stir evenly, you can get out of the kettle. Finally, the finished product is obtained after grinding 3 times with a three-roll mill. The properties of the grease obtained are shown in Table 1.

Embodiment 3

[0043] Inorganic grease composition provided by the invention, component and mass percent are as follows:

[0044] (1) No. 1500 synthetic cylinder oil 69.5%;

[0045] (2) Modified bentonite 14.0%;

[0046] (3) Active calcium carbonate 11.5%;

[0047] (4) Acetone 3.8%;

[0048] (5) phenothiazine 1.2%;

[0049] Put No. 1500 synthetic cylinder oil into the kettle, raise the temperature to 70°C, add 140g of aminated bentonite and 115g of activated calcium carbonate, and stir for 8 minutes to disperse the materials. Add auxiliary dispersant, keep the temperature and stir for 30min. Put the remaining base oil into the kettle and stir for 80 minutes. At a temperature of 83°C, the phenothiazine was added. Stir evenly, you can get out of the kettle. Finally, the finished product is obtained after grinding 3 times with a three-roll mill. The properties of the grease obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com