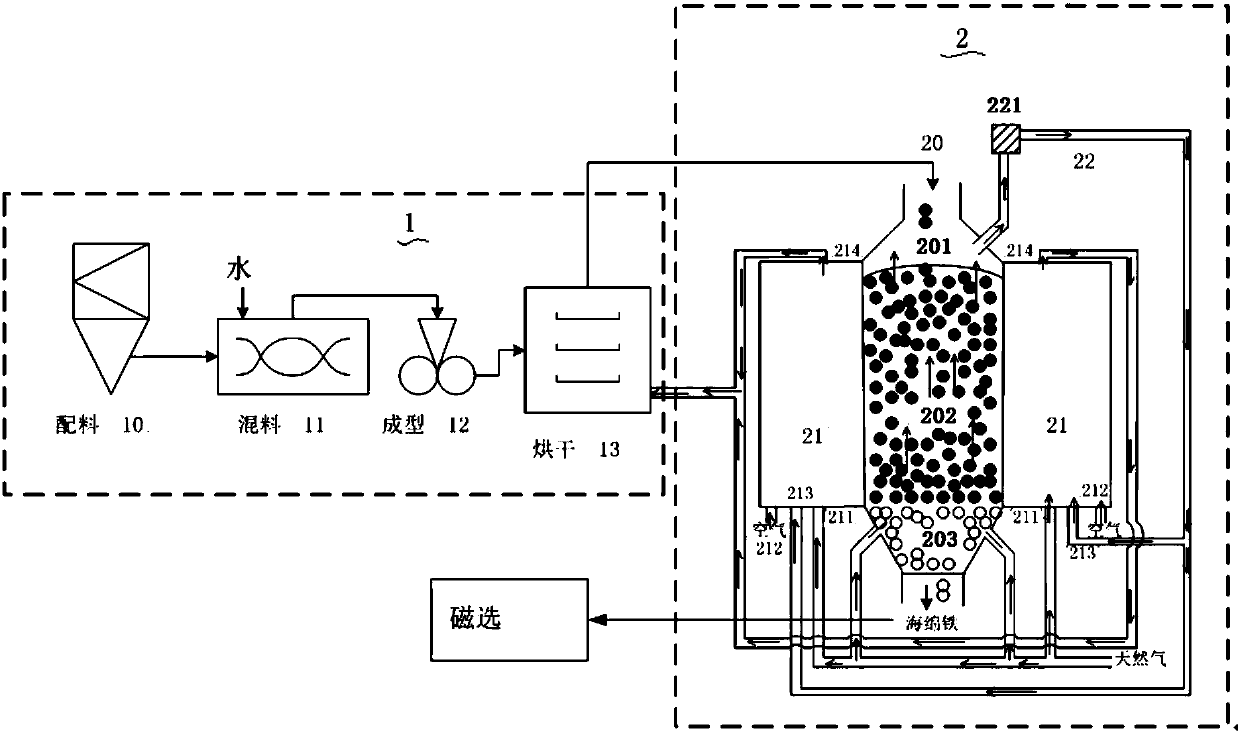

System and method for producing sponge iron by gas-based shaft furnace

A gas-based shaft furnace and sponge iron technology, applied in shaft furnaces, furnaces, furnace types, etc., can solve the problems of long process flow, high requirements on raw material conditions, low heat release, etc., to shorten the process flow and shorten the reaction time. , the effect of increasing the smelting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 5 parts of bentonite and 5 parts of water to 100 parts of hematite powder, mix them evenly, and then send them to a briquette machine for compacting to obtain green pellets with a particle size of 15-20mm. Put it into the drying device for drying, and dry for 2-3 hours, and the dry pellets after drying are sent to the air-based shaft furnace. Before the dry pellets are fed into the gas-based shaft furnace, natural gas and combustion-supporting air are introduced into the combustion chamber of the gas-based shaft furnace to heat the body of the gas-based shaft furnace. After the temperature in the reduction section is measured to be between 900°C and 1000°C, if In this embodiment, the temperature is 980°C, iron ore powder dry pellets are added from the feeding section, and natural gas is fed through the gas inlet at the bottom of the gas-based shaft furnace. After reacting for 20-30 minutes, open the top gas inlet of the combustion chamber, let the top gas and air wa...

Embodiment 2

[0052] Prepare 100 parts of hematite powder, mix with 3 parts of bentonite, 2 parts of starch and 8 parts of water, and then send it to a briquetting machine for pressing to form green pellets with a particle size of 15-20mm. The pellets are sent to the drying device for drying for 2-3 hours, and the dried pellets are sent to the air-based shaft furnace. Before the dry pellets are fed into the gas-based shaft furnace, natural gas and combustion-supporting air are introduced into the combustion chamber of the gas-based shaft furnace to heat the body of the gas-based shaft furnace. After the temperature in the reduction section is measured to be between 900°C and 1000°C, if In this embodiment, the temperature is 900°C, iron ore powder dry pellets are added from the feeding section, and natural gas is fed through the air inlet at the bottom of the gas-based shaft furnace. After reacting for 20-30 minutes, open the top gas inlet of the combustion chamber, let the top gas and air w...

Embodiment 3

[0054] Prepare 100 parts of hematite powder, mix with 4 parts of bentonite, 1 part of starch and 7 parts of water, and then send it to a briquetting machine for pressing to form green pellets with a particle size of 15-20mm. The pellets are sent to the drying device for drying for 2-3 hours, and the dried pellets are sent to the air-based shaft furnace. Before the dry pellets are fed into the gas-based shaft furnace, natural gas and combustion-supporting air are introduced into the combustion chamber of the gas-based shaft furnace to heat the body of the gas-based shaft furnace. After the temperature in the reduction section is measured to be between 900°C and 1000°C, if In this embodiment, the temperature is 1000°C, iron ore powder dry pellets are added from the feeding section, and natural gas is fed through the air inlet at the bottom of the gas-based shaft furnace. After reacting for 20-30 minutes, open the top gas inlet of the combustion chamber, let the top gas and air w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com