Functional sports garment fabric

A sportswear, functional technology, applied in the field of clothing fabrics, can solve the problems of poor scratch resistance, high frequency of replacement, uncomfortable skin, etc., to achieve the effect of increasing wrinkles, increasing convective gaps, and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

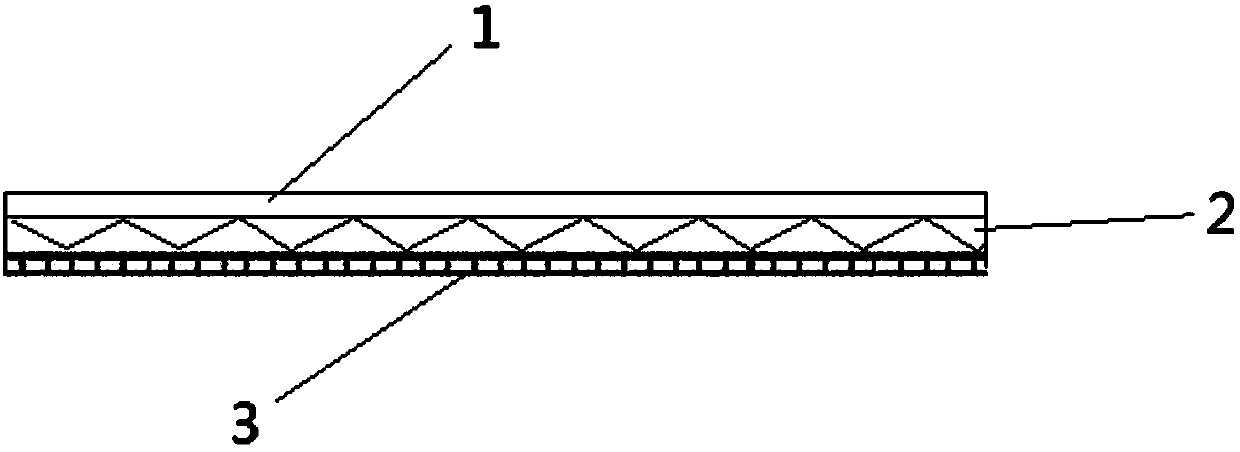

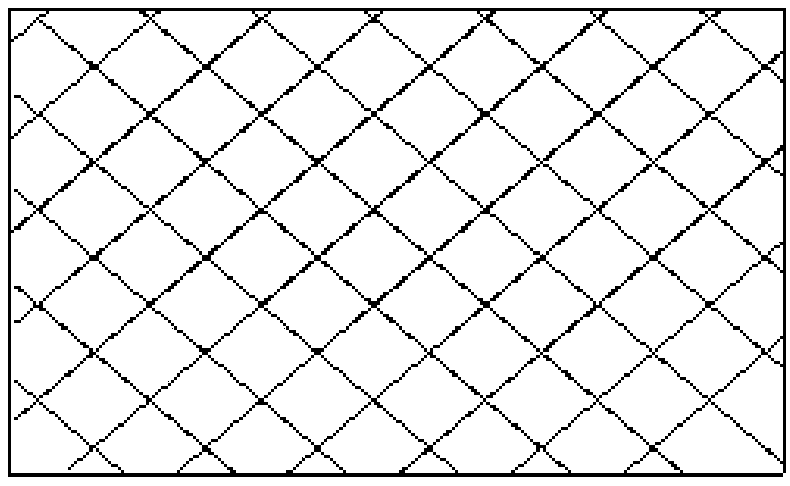

[0031] A functional sportswear fabric, its structure is as figure 1 As shown, it comprises sequentially compounded fabric outer layer 1, fabric middle layer 2 and fabric inner layer 3, wherein, fabric outer layer 1 adopts round fiber as outer layer warp yarn 11, special-shaped fiber as outer layer weft yarn 12, and is formed by outer layer The warp yarn 11 is interwoven with the outer weft yarn 12, and the middle layer 2 of the fabric is woven into a grid cloth structure by twisting hollow polyester filament 21 and high-elastic polyester yarn. image 3 As shown, the inner layer 3 of the fabric uses spandex core-spun yarn as the inner layer warp yarn 31, milk protein fibers 33 and bamboo charcoal fibers 34 arranged at intervals as the inner layer weft yarn 32, and then the inner layer warp yarn 31 and the inner layer weft yarn 32 are interwoven .

Embodiment 2

[0033] On the basis of embodiment 1, this embodiment is further set to:

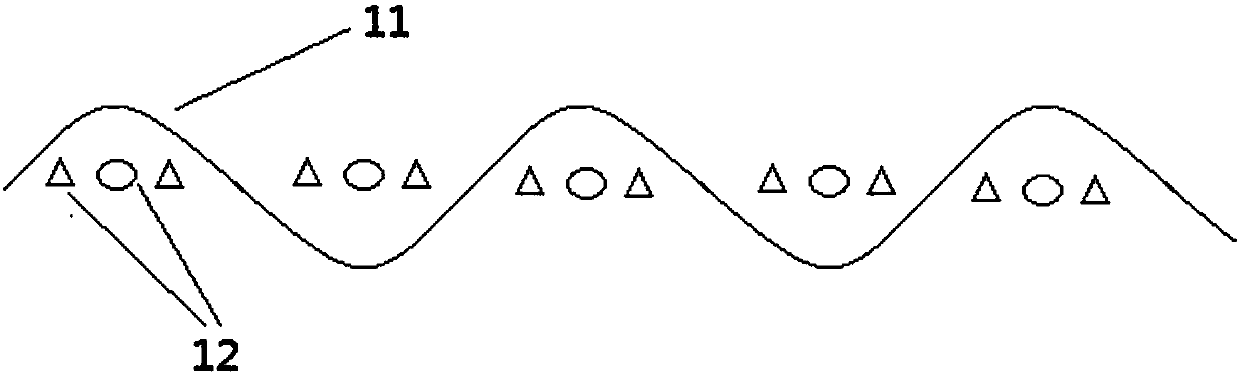

[0034] see figure 2 As shown, the shaped fibers are oval fibers or triangular fibers.

Embodiment 3

[0036] On the basis of embodiment 1, this embodiment is further set to:

[0037] The shrinkage rate of the round fiber is higher than that of the shaped fiber, so that the heat-treated outer warp yarn 11 shrinks and arches the outer weft yarn 12 to form a concave-convex structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com