Processing process of lamp tube with high switching frequency and processing apparatus thereof

A technology of switching times and processing equipment, which is applied in the manufacture of discharge tubes/lamps, electrical components, cold cathodes, etc., and can solve problems such as being too strong, not drying in time, and low switching times of lamp tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

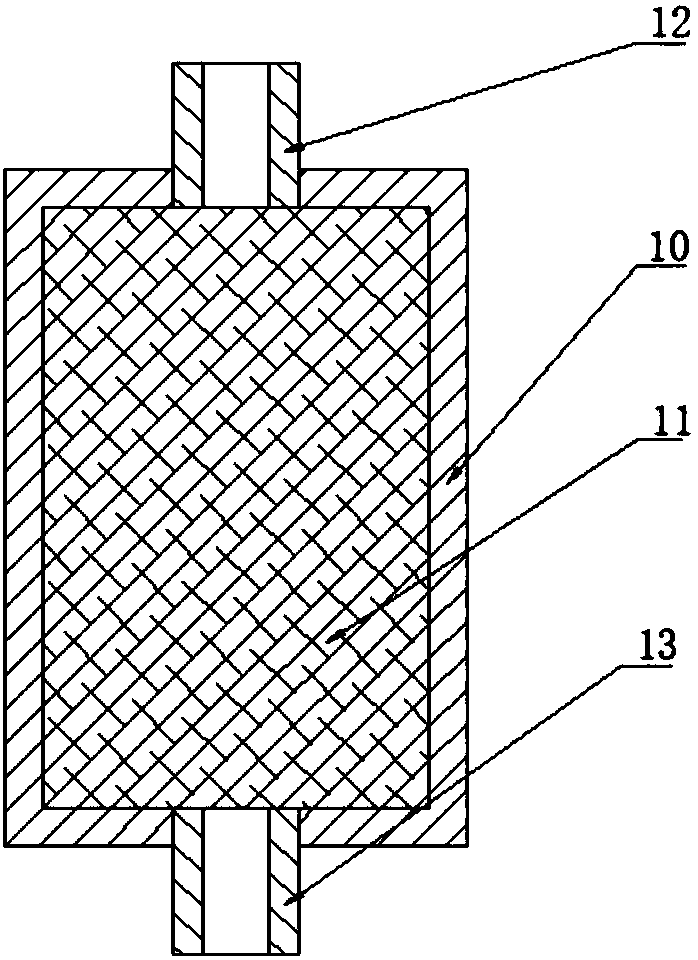

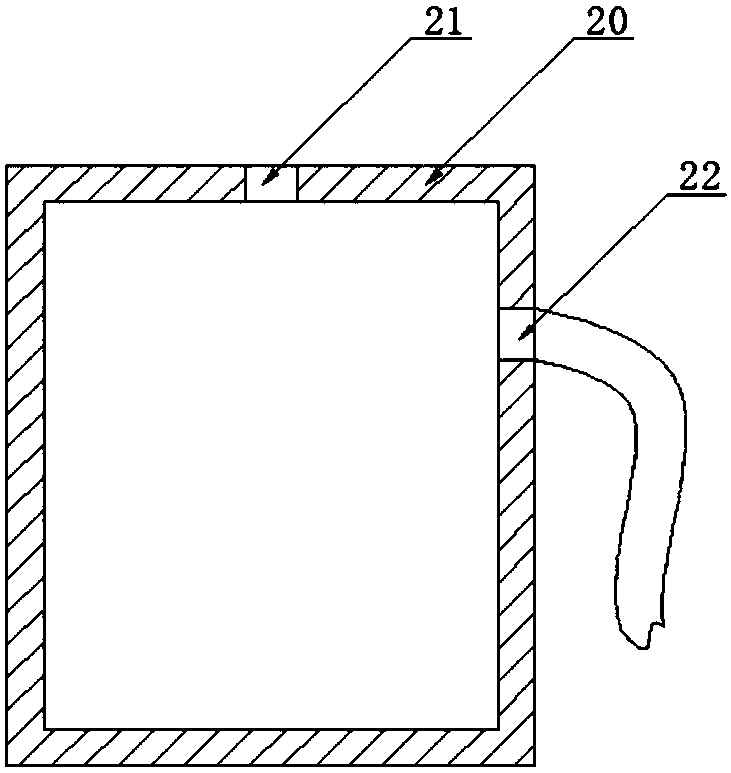

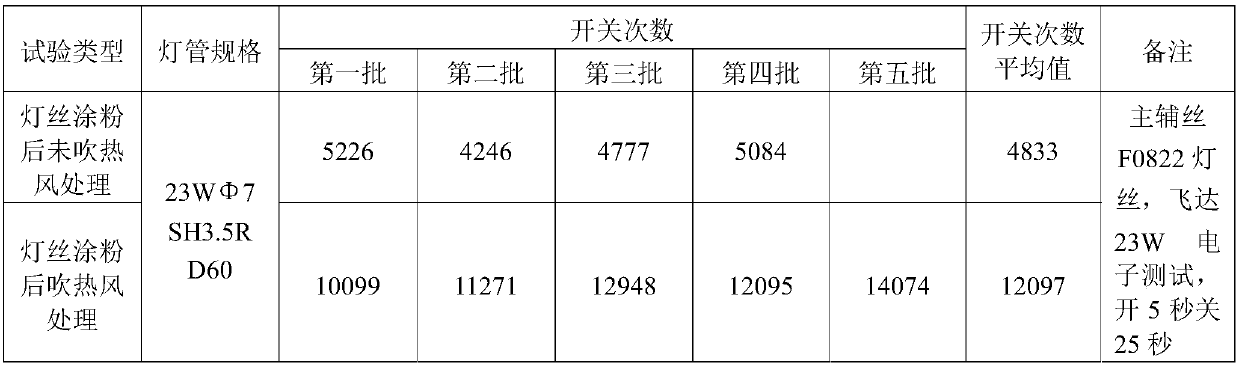

[0029] The invention discloses a processing technology for a high-switching lamp tube, which is characterized in that it comprises the following steps: (1) putting the filament of the lamp tube into a slurry tank for electronic powder coating treatment, and at the same time energizing the slurry tank (2) Put the filament of the lamp tube after the treatment in step (1) on the upper part of the hot air blowing device for hot air blowing treatment, and dry the electronic powder on the lamp tube filament; the temperature of the hot air blown out by the hot air blowing device is: 83°C, the filament blowing hot air time of the lamp tube is controlled at: 1.2 seconds, the electronic powder in the slurry tank is fed with 2 mA DC for electrophoresis coating; the conductivity of the electronic powder slurry is 30us / cm, Such as image 3 As shown, after the filament of the lamp tube is coated with electronic powder, the hot air blowing device immediately blows hot air on the wet electron...

Embodiment 2

[0031] The invention discloses a processing technology for a high-switching lamp tube, which is characterized in that it comprises the following steps: (1) putting the filament of the lamp tube into a slurry tank for electronic powder coating treatment, and at the same time energizing the slurry tank (2) Put the filament of the lamp tube after the treatment in step (1) on the upper part of the hot air blowing device for hot air blowing treatment, and dry the electronic powder on the lamp tube filament; the temperature of the hot air blown out by the hot air blowing device is: 88 ℃, the filament blowing hot air time of the lamp tube is controlled at: 1.4 seconds.

[0032] The electronic powder in the slurry tank is supplied with 8 mA direct current for electrophoretic coating; the electrical conductivity of the electronic powder slurry is 30 us / cm.

Embodiment 3

[0034] The invention discloses a processing technology for a high-switching lamp tube, which is characterized in that it comprises the following steps: (1) putting the filament of the lamp tube into a slurry tank for electronic powder coating treatment, and at the same time energizing the slurry tank (2) Put the filament of the lamp tube after the treatment in step (1) on the upper part of the hot air blowing device for hot air blowing treatment, and dry the electronic powder on the lamp tube filament; the temperature of the hot air blown out by the hot air blowing device is: 78°C, the filament blowing time of the lamp tube is controlled at 1.0 seconds, and the electronic powder in the slurry tank is supplied with 5 mA DC for electrophoresis coating; the conductivity of the electronic powder slurry is 30 us / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com