Intelligent hot-spot resistant photovoltaic assembly

A photovoltaic module and hot spot technology, applied in the field of solar photovoltaic power generation, can solve the problems of reduced module output power, increased module power loss, limited protection function, etc., to maximize the overall output, eliminate mismatch, and achieve intelligent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the technical features and content of the present invention, the following description will be made in conjunction with the accompanying drawings.

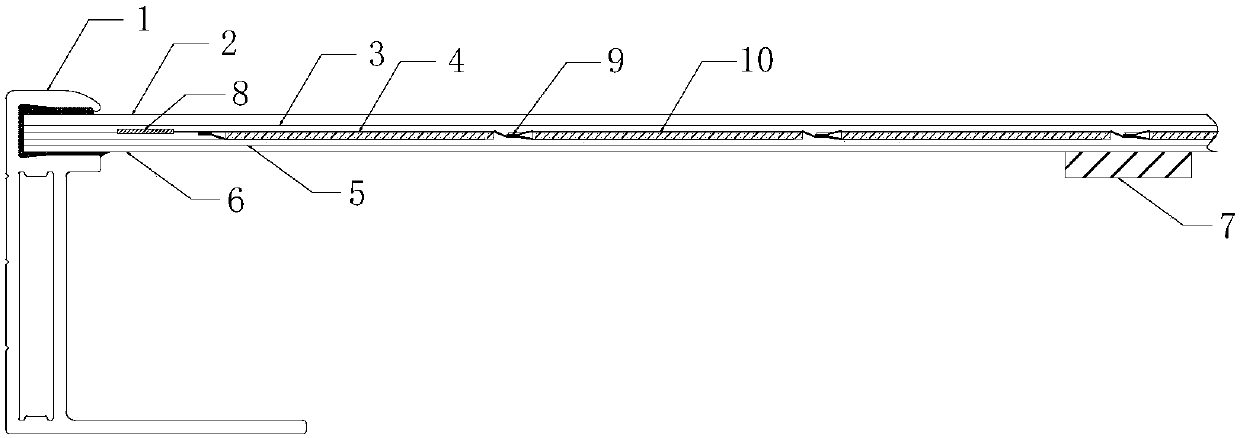

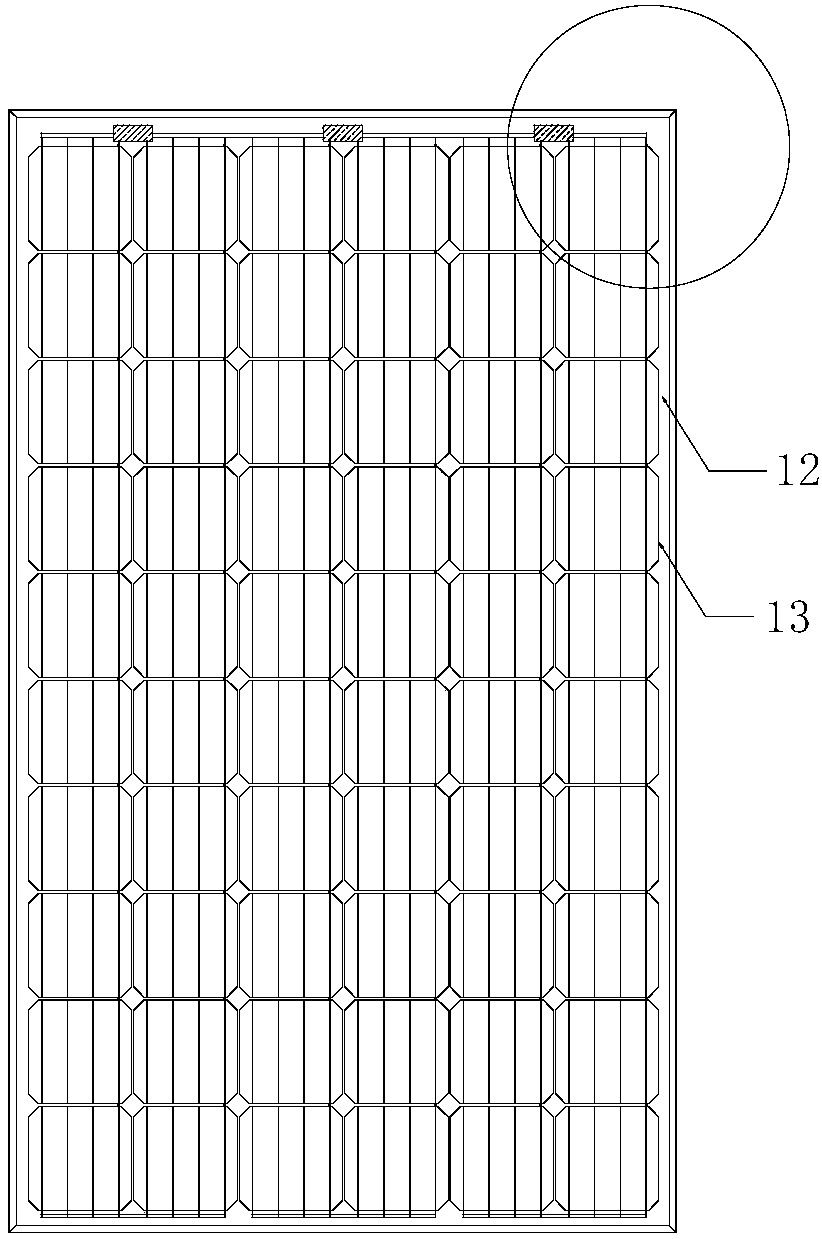

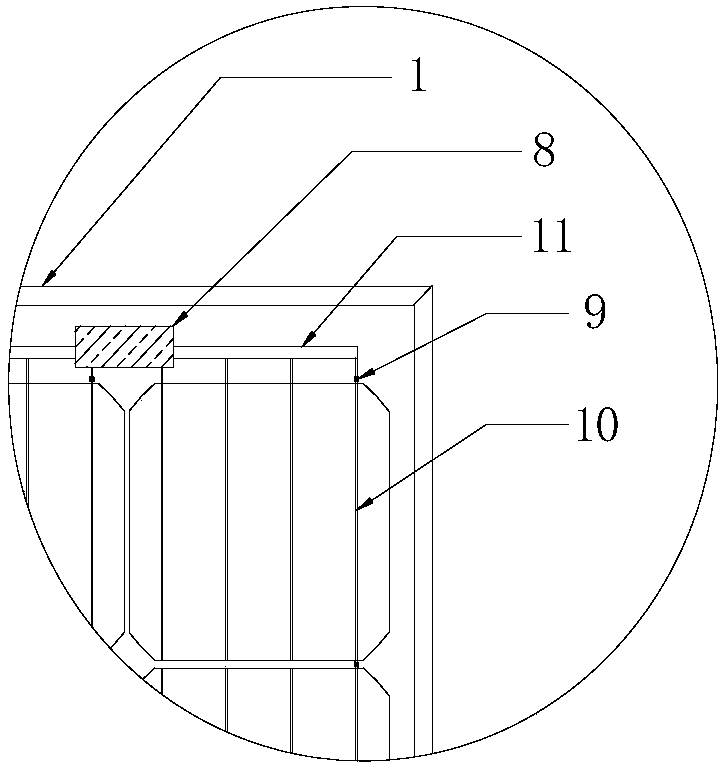

[0029] like figure 1 , figure 2 and image 3 As shown, an intelligent anti-hot spot photovoltaic module includes an aluminum alloy frame 1, a first cover layer 2, a first encapsulation layer 3, a cell layer 4, a second encapsulation layer 5, a second cover layer 6 and wiring Box 7. The battery sheet layer 4 includes a plurality of battery strings 12 , and the battery strings are composed of a plurality of battery sheets welded in series by a plurality of welding ribbons 10 , and the battery strings are connected by bus strips 11 . The battery sheet layer 4 is also provided with a number of power optimization chips 8 and diode chips 9, the power optimization chips are connected in series and parallel with the battery, and the diode chips are connected in reverse parallel with the battery sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com