Microporous diaphragm of external coating of lithium ion battery and matching coating slurry formula

A technology of lithium-ion batteries and microporous diaphragms, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., and can solve problems such as easy wear of the diaphragm, no solution, and deterioration speed. Achieve the effects of simple stacking structure, easy external process, and improved current uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further illustrated below by way of examples.

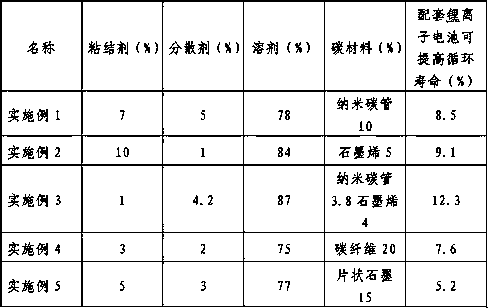

[0014] The invention relates to a microporous diaphragm used for the external coating of the lithium ion battery between the electrodes of the lithium ion battery. The microporous diaphragm is used as the base material, and coatings are respectively provided on the two planes of the microporous diaphragm. The thickness of the coating directly attached to the microporous separator is extremely thin, requiring only 1-5 μm after the coating is dried. The coating applied in the present invention is a kind of conductive coating, which is prepared according to the slurry before painting, and its formula consists of the following components measured by weight percentage, binder 1-10%, dispersant 1-5% , solvent 75-87% and carbon material 5-20%. The carbon material in the component is the core material of the coating slurry, and its quality determines the conductivity on the diaphragm surface. The choice ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com