Release sheet and adhesive material

A technology of peeling sheet and peeling agent layer, which is applied in the direction of adhesive products, film/sheet adhesives, adhesives, etc., can solve the problems of difficulty in deployment, static electricity, sparks, etc. Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

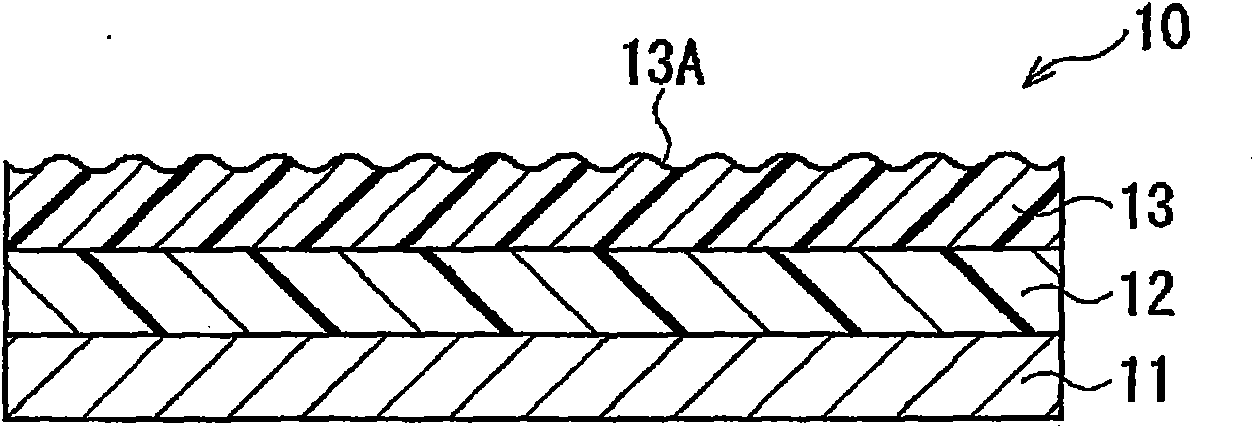

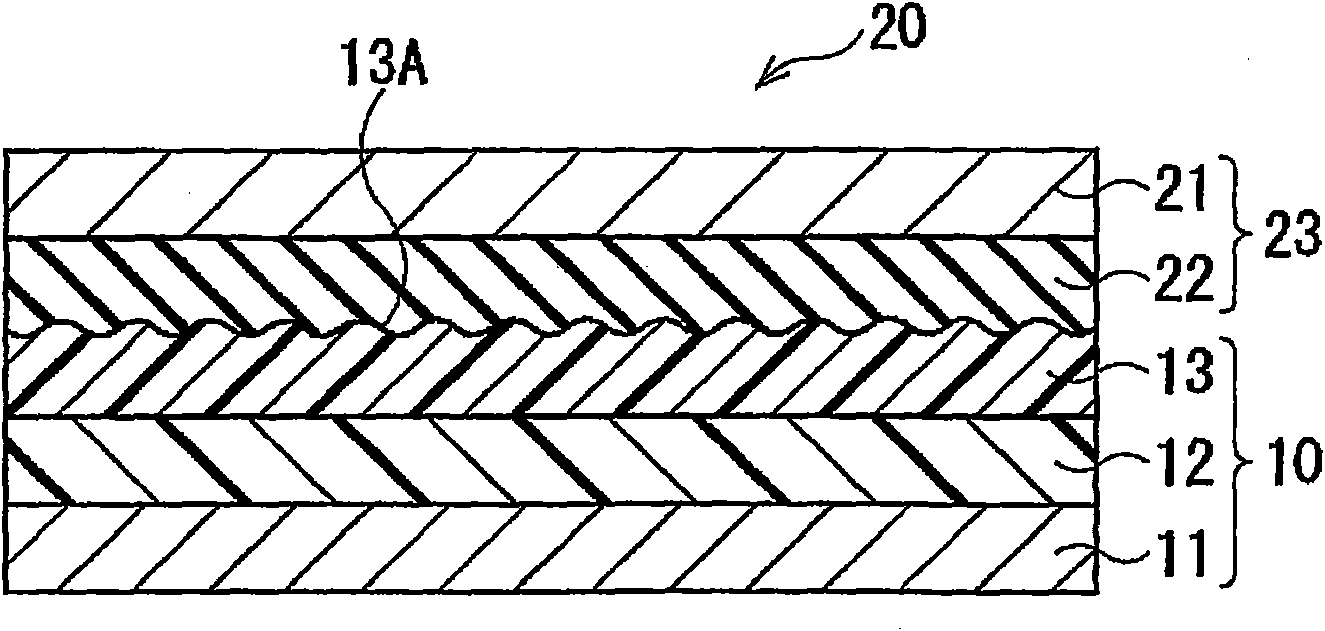

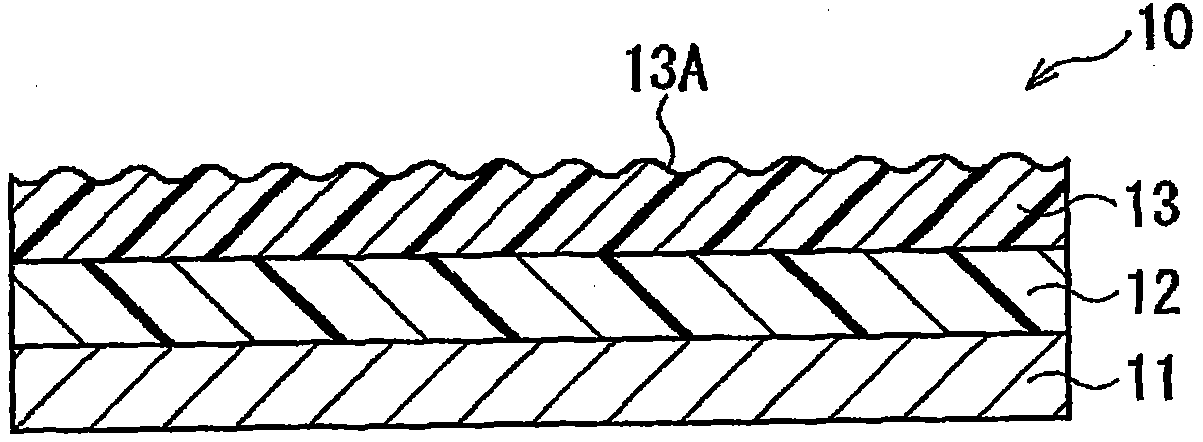

[0041] By mixing 70 parts by weight of low-density polyethylene (trade name: Novatec LD LC605Y, manufactured by Japan Polyethylene Corp.) with a density of 0.918 g / cm3 and 30 parts by weight of an antistatic agent of polyether-polypropylene block copolymer ( Trade name: Pelestat 230, manufactured by Sanyo Chemical Industries, Ltd.) The undercoat composition obtained was melted, then extruded and coated at a temperature of 320° C. on a general-purpose PET film with a thickness of 38 μm (trade name : Lumirror S-28 manufactured by Toray Industries Inc.) to form an undercoat layer with a thickness of 15 μm. Next, by mixing 70 parts by weight of an ethylene-1-butene copolymer (trade name: Excellen EUL731, manufactured by Sumitomo Chemical Co., Ltd) with a density of 0.895 g / cm3 and 30 parts by weight with a density of 0.918 g / cm3 A release agent composition obtained from low-density polyethylene (trade name: Novatec LD LC604, manufactured by JapanPolyethylene Corp.) was extruded an...

Embodiment 2

[0043] The step of embodiment 2 is similar to embodiment 1, different is the mixture resin obtained by mixing 50 parts by weight of low-density polyethylene (trade name: Novatec LD LC605Y) and 50 parts by weight of antistatic agent (trade name: Pelestat 230) Basecoat composition for release sheets.

Embodiment 3

[0045] The step of embodiment 3 is similar to embodiment 1, and difference is that by mixing 50 parts by weight density is the low-density polyethylene (trade name: Novatec LDLC800, manufactured by Japan Polyethylene Corp.) and 50 parts by weight A mixture resin obtained from an ethylene-propylene copolymer (trade name: Tafmer P0280G, manufactured by Mitsui Chemical Inc.) having a density of 0.870 g / cm3 was used as a release agent composition for a release sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com