DFB laser and manufacturing method thereof

A technology of DFB lasers and manufacturing methods, which is applied in the field of lasers, can solve problems and cannot meet the needs of use, and achieve the effect of easy reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

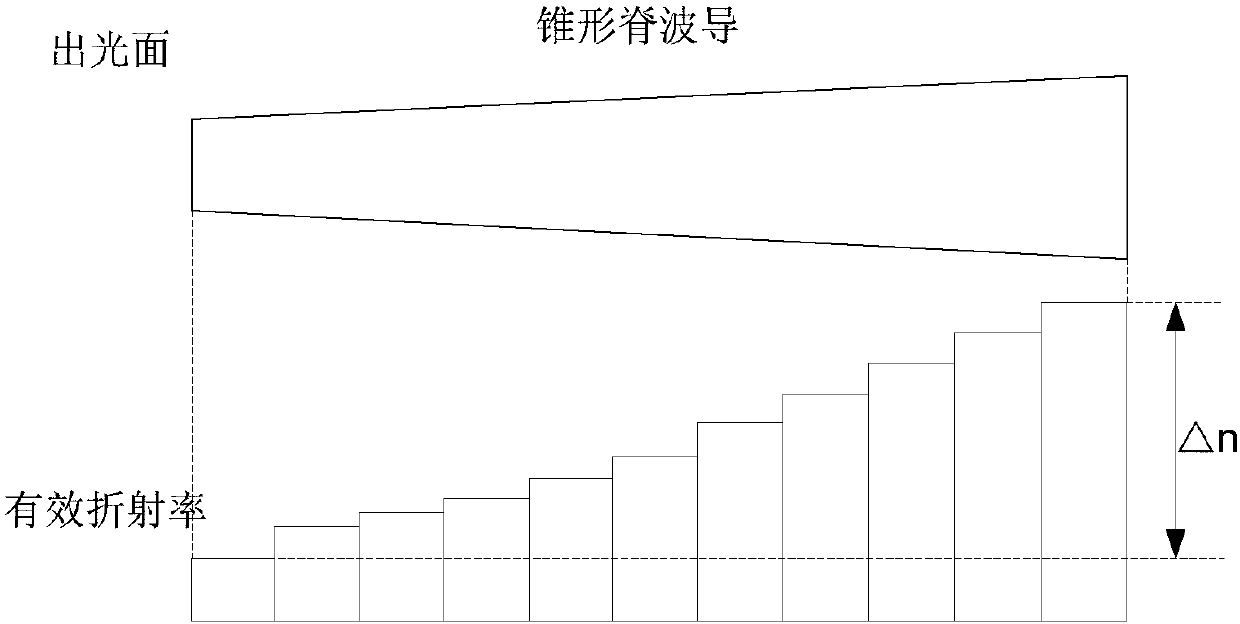

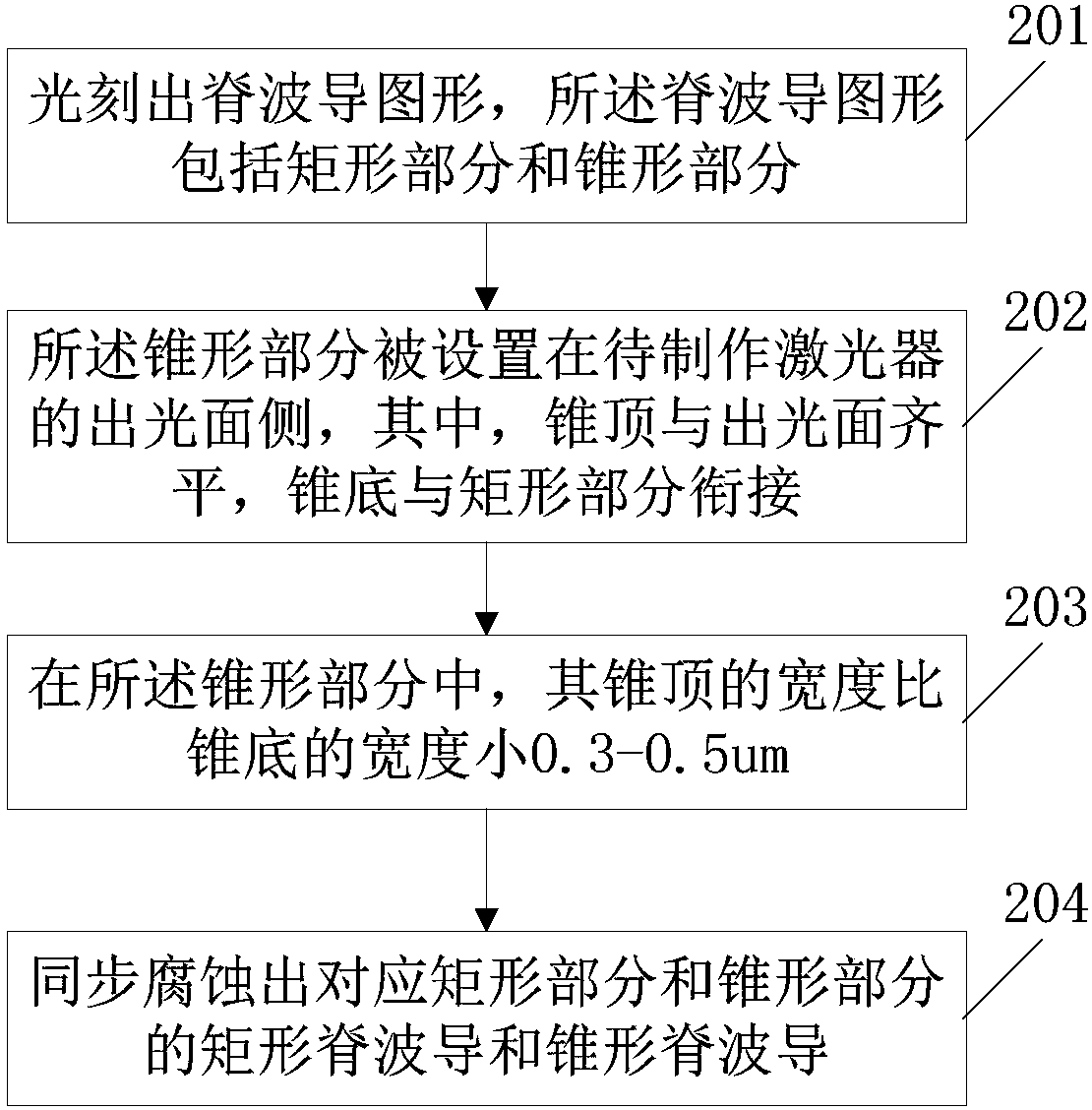

[0086] Embodiment 1 of the present invention provides a method for manufacturing a DFB laser. A buffer layer, a lower confinement layer, an active layer, an upper confinement layer, an etching stop layer, and a grating layer are fabricated on a substrate, and it is characterized in that, in the corrosion ridge waveguide, such as figure 2 As shown, the methods include:

[0087] In step 201, a ridge waveguide pattern is photoetched, and the ridge waveguide pattern includes a rectangular portion and a tapered portion.

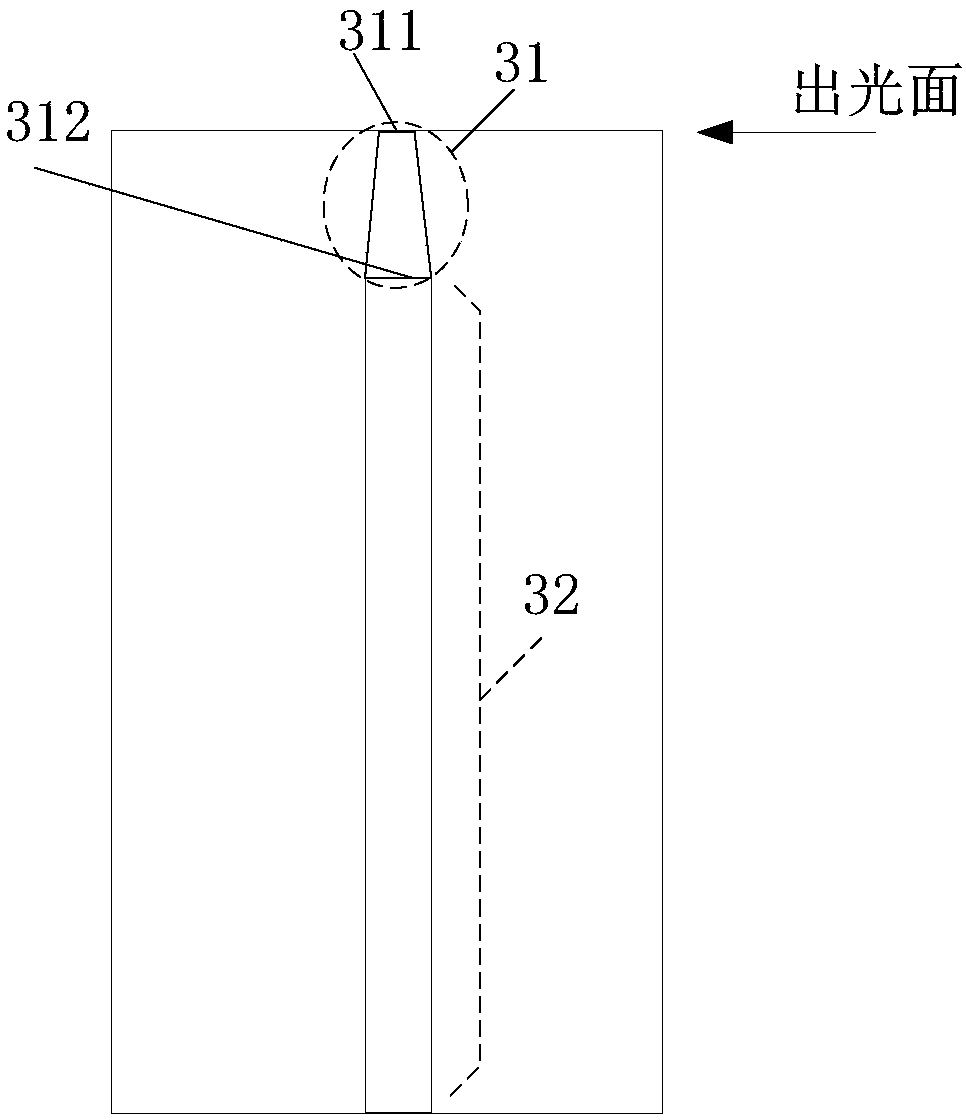

[0088] Such as image 3 As shown, a rectangular portion 32 and a tapered portion 31 in the ridge waveguide pattern are marked by a plan view and a dotted line frame.

[0089] In step 202, the tapered portion is arranged on the light-emitting surface side of the laser to be fabricated, wherein the cone top 311 is flush with the light-emitting surface, and the cone bottom 312 is connected to the rectangular portion.

[0090] In step 203, in the tapered part, the...

Embodiment 2

[0120] In the embodiment of the present invention, in addition to providing the DFB laser manufacturing method as described in Embodiment 1, a DFB laser structure completed by the manufacturing method described in Embodiment 1 is also provided, such as Figure 8 As shown, including substrate, buffer layer, lower confinement layer, active layer, upper confinement layer, etch stop layer and grating layer, specifically including:

[0121] An N-InP buffer layer 2 is grown on the InP substrate 1;

[0122] An N-InAlAs layer 3 and an InAlGaAs layer 4 with a graded Al composition are grown sequentially on the N-InP buffer layer 2;

[0123] growing a multi-quantum well active layer 5 on the graded layer;

[0124] On the multi-quantum well active layer 5, an InAlGaAs layer 6 and a P-InAlAs layer 7 with a graded Al composition are grown sequentially;

[0125] A P-InP space layer 8 and an etching stop layer 9 are sequentially grown on the P-InAlAs layer 7;

[0126] A ridge waveguide st...

Embodiment 3

[0130] In the embodiment of the present invention, in addition to providing the DFB laser manufacturing method as described in Embodiment 1, a DFB laser structure completed by the manufacturing method described in Embodiment 1 is also provided, such as Figure 7 As shown, the structure of each layer from bottom to top includes:

[0131] Substrate 1-0, which is an N-type InP layer;

[0132] a buffer layer 1-1, which is an N-type InP layer and formed on the substrate 1-0;

[0133] The first graded confinement layer 1-2, which is N-type InAl x Ga 1-x The As layer is formed on the buffer layer 1-1, x=0.5-0.1;

[0134] A first waveguide layer 1-3, which is an N-type InP layer and formed on the first graded confinement layer 1-2;

[0135] The second confinement layer 1-4, which is N-type InAl 0.5 Ga 0.5 An As layer is formed on the first waveguide layer 1-3;

[0136] The first quantum well barrier layer 1-5, which is non-doped Al 0.3 Ga 0.7 An InAs layer is formed on the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com