Powder metallurgy segment re-punching die

A powder metallurgy and fan-shaped sheet technology, applied in the field of powder metallurgy re-blanking dies, can solve the problems of inconvenient maintenance and repair, poor operation stability, low blanking quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

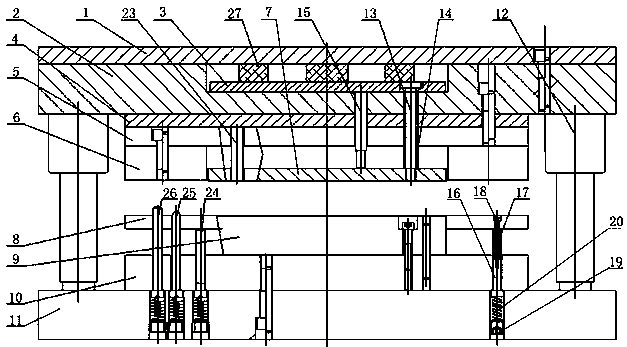

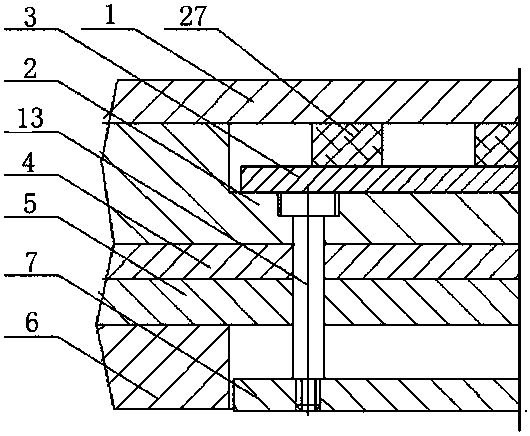

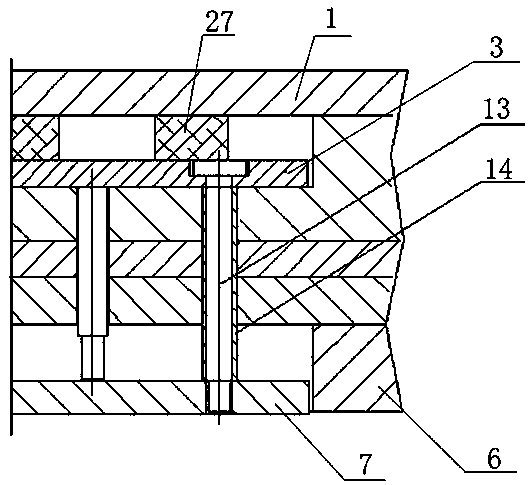

[0014]The powder metallurgy fan-shaped piece compound punching die includes a compound punching die body, and the compound punching die body includes an upper die cover plate 1, an upper die seat 2, a punching plate 3, an upper backing plate 4, an upper fixing plate 5, a die 6, and a push plate 7 , unloading plate 8, punch 9, lower fixing plate 10, lower mold base 11, ball guide post 12, the upper surface of said beating plate 3 has a countersunk through hole, and the bottom of the beating cavity of said upper die base 2 , the upper backing plate 4 and the upper fixing plate 5 are provided with punching bolt holes corresponding to the through holes of the countersunk head, and the punching bolts whose lower ends are screwed on the push plate 7 are provided in the through holes of the countersunk head and the punching bolt holes. The material bolt 13 is covered with a material contour cover 14, the upper end of the material contour cover 14 is supported on the lower surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com