Process for harmless treatment of organic fertilizer

A harmless treatment and organic fertilizer technology, applied in the field of organic fertilizer, can solve the problems of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

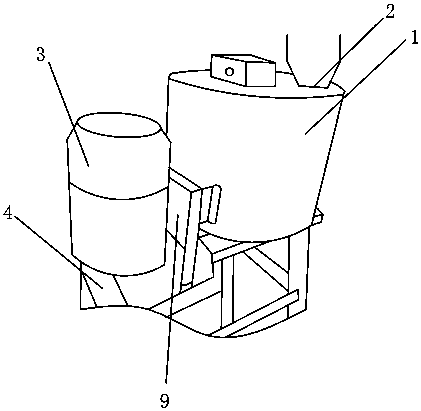

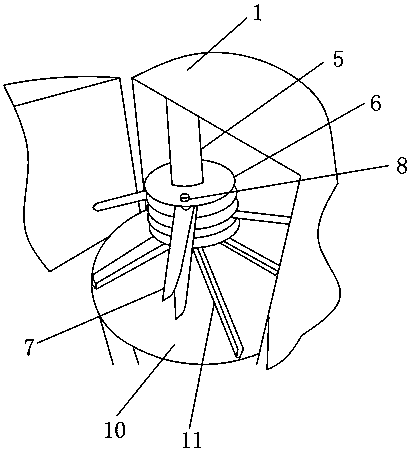

[0022] Reference Figure 1 to Figure 2 As shown, the harmless treatment process of organic fertilizer and the harmless treatment process of organic fertilizer implemented in this case include the following steps: (1) pulverize the raw materials through a pulverizer; (2) then go through natural dehydration. After 2 5-10 days of natural dehydration, the water content of the raw materials is between 60-70%; (3) Add organic fluff, and the prepared organic fluff, the machine fluff is grain chaff, sawdust or crushed straw, Stir well with a shovel to make the moisture content reach about 40-50%, and the mass ratio of fluff to the raw material is 5:1; (4) Inoculate the bacteria, inoculate the raw materials; (5) Initial fermentation, start the inoculation of raw materials Fermentation is heating up, and the temperature of the fertilizer pile is measured at 8 o’clock, 12 o’clock, and 16:00 every day; (6) Turn the pile, when the temperature of the raw material pile rises to 60-70 degrees ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com