A preparation method of high-strength, high-modulus, high-temperature-resistant polyurethane elastic fiber

A polyurethane elastic, high-strength and high-modulus technology is applied in the fields of fiber chemical characteristics, single-component synthetic polymer rayon, chemical post-treatment of synthetic polymer rayon, etc., so that it is not easy to break, improve strength, and not easy to break internally. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

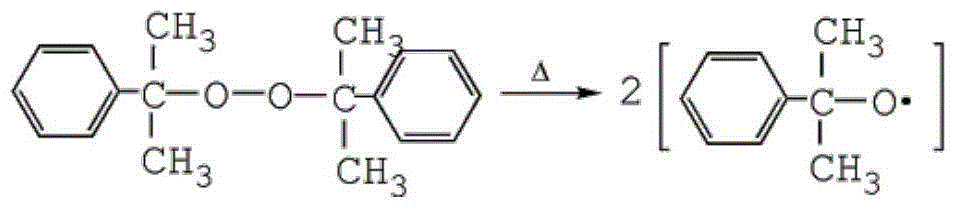

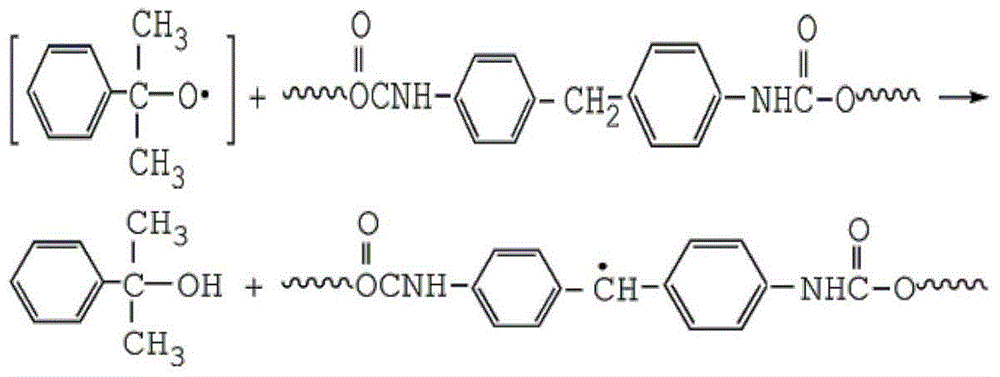

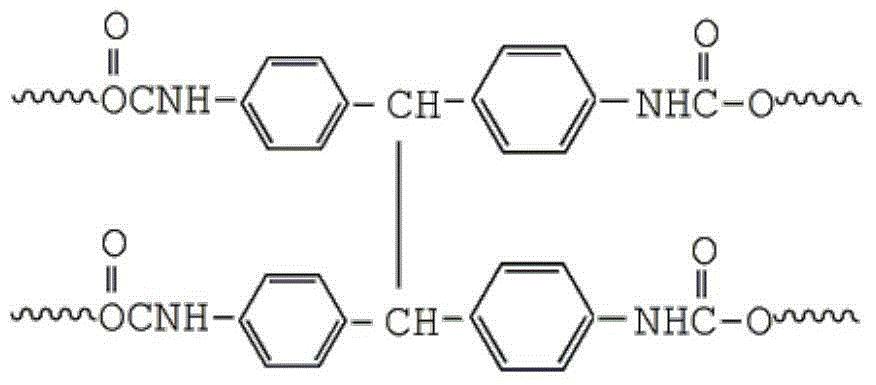

Method used

Image

Examples

specific example

[0048] The following implementation cases are only exemplary implementation cases, and the protection scope of the present invention is not limited thereto.

[0049] Control sample: preparation of control sample

[0050] Measure 5.27Kg of solvent dimethylacetamide (DMAC) into the pre-reaction kettle, start stirring, add 9.50Kg of polytetrahydrofuran ether glycol (PTMEG, number average molecular weight 1810) into the pre-reaction kettle, and cool the reaction kettle to 23°C in a water bath After 15 minutes of constant temperature, 2.495Kg of diphenylmethane diisocyanate (MDI) was added to the pre-reaction kettle. After 20 minutes of reaction, the pre-reaction kettle was heated to 55°C in a water bath and reacted at a constant temperature for 3.5 hours to obtain the prepolymer PPS. Transfer the PPS into the chain extension reactor, add 16.775Kg solvent DMAC to the pre-reactor, clean the pre-reactor, transfer the solvent into the chain extension reactor, start stirring, cool the ...

Embodiment 1-3

[0056] The preparation of embodiment 1-3 experimental sample

[0057] When preparing the samples of Examples 1-3, the experimental operation method is the same as that of the comparison sample, except that before the curing, a certain proportion of organic peroxide dicumyl peroxide (DCP) must be added to the curing kettle. The added ratio is shown in the data in Table 2:

[0058] Table 2 Experimental sample 1-3DCP addition ratio

[0059]

[0060] Among them: 1) Number of moles: nEDA+nPDA=nMDI-nPTMEG-nDEA / 2

[0061] 2) A is the solid content of the polymer polymerized in the chain extension reactor, that is, A is the sum of the mass of the following substances: A=mPTMEG+mMDI+mEDA+mPDA+mDEA

[0062] Each embodiment polyurethane elastic fiber physical index is listed in table 3:

[0063] Table 3 each embodiment polyurethane elastic fiber physical property index

[0064]

[0065]

[0066] Among them: SS300 is the strength when the fiber is stretched by 300%, DS is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com