Multidentate nitrogen-oxygen tertiary amine ligand Ga-In complex and preparation method and application thereof

A polydentate nitroxide tertiary amine and nitroxide tertiary amine technology, which is applied in chemical instruments and methods, compounds containing elements of Group 3/13 of the periodic table, and organic compounds of Group 3/13 without C-metal bonds, etc., It can solve the problem that the catalytic performance of the lactide ring-opening polymerization catalyst needs to be improved, and achieve good activity and stereoselectivity, and improve the catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

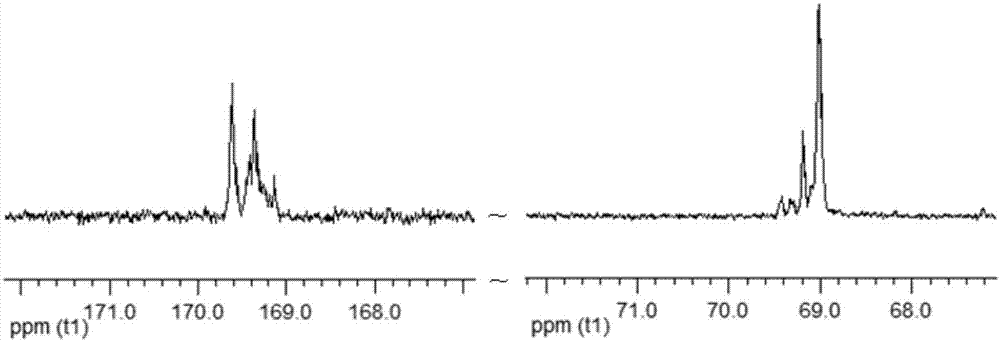

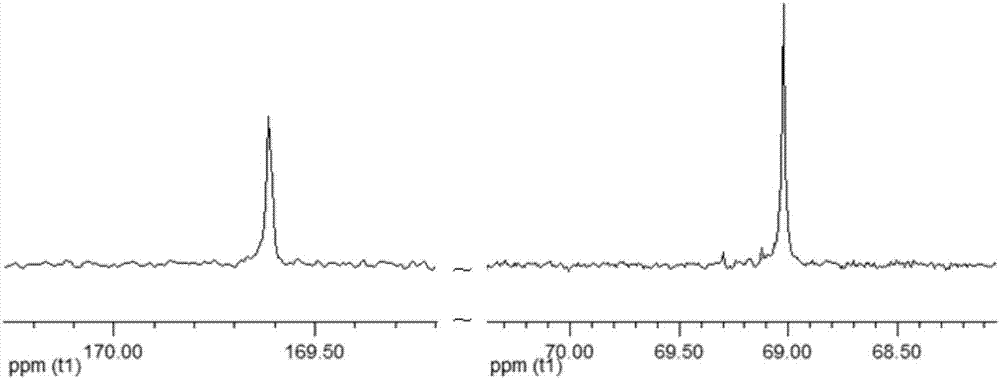

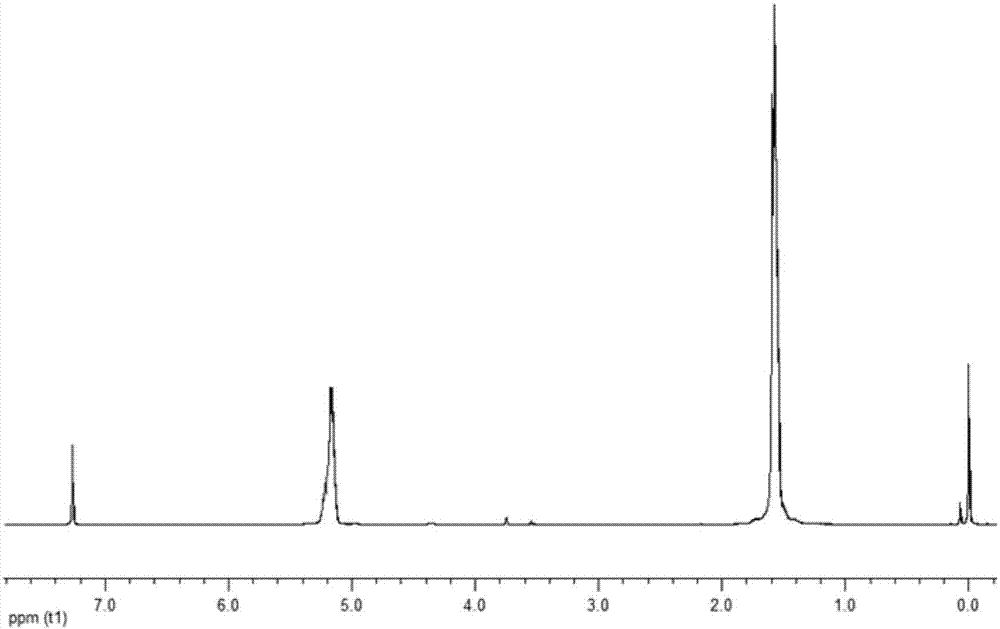

[0030] Specific implementation mode 1: The chemical structural formula of the polydentate nitroxide tertiary amine ligand Ga, In complex in this implementation mode is:

[0031]

[0032] Wherein M=In or Ga, X=Cl, O i Pr, OEt or O t Bu; R 1 is H, Cl, Br, I, Me, i Pr, tBu or cumyl (cumyl), R 2 is H, Cl, Br, I, Me, i Pr, t Bu or cumyl, R 3 for Cl, Br, t Bu or Me, R 4 for Cl, Br, t Bu or Me.

[0033] In this embodiment, asymmetric nitroxide multidentate ligands are used to synthesize lactide ring-opening polymerization metal gallium and indium complex catalysts, which can prepare polylactide with narrow molecular weight distribution and stereoregularity.

specific Embodiment approach 2

[0034] Specific embodiment two: the preparation method of multidentate nitroxide tertiary amine ligand Ga, In complex in this embodiment is implemented according to the following steps:

[0035] Under nitrogen protection, add organic medium to the schlenk bottle, add NaH (at room temperature) and stir for 0.3-0.6 hours, then add asymmetric N 2 o 2 Ligand, continue to stir for 3 to 6 hours, cool down to 0°C, and then add anhydrous GaCl 3 or InCl 3 , stirred at room temperature for 10 to 14 hours, and the filtrate after pressure filtration was precipitated at a temperature of -18 to -22°C to obtain a multidentate nitrogen oxide tertiary amine ligand Ga, In complex;

[0036] where the asymmetric N 2 o 2 The structural formula of the ligand is L A or L B , L A for L B for R in the structural formula 1 is H, Cl, Br, I, Me, i Pr, t Bu or cumyl (cumyl), R 2 is H, Cl, Br, I, Me, i Pr, t Bu or cumyl, R 3 for Cl, Br, t Bu or Me, R 4 for Cl, Br, t Bu or Me.

[0037...

specific Embodiment approach 3

[0038] Specific embodiment three: the difference between this embodiment and specific embodiment two is that NaH and asymmetric N 2 o 2 The molar ratio of ligands is 1:2-1:4. Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com